214325 108 Revision A

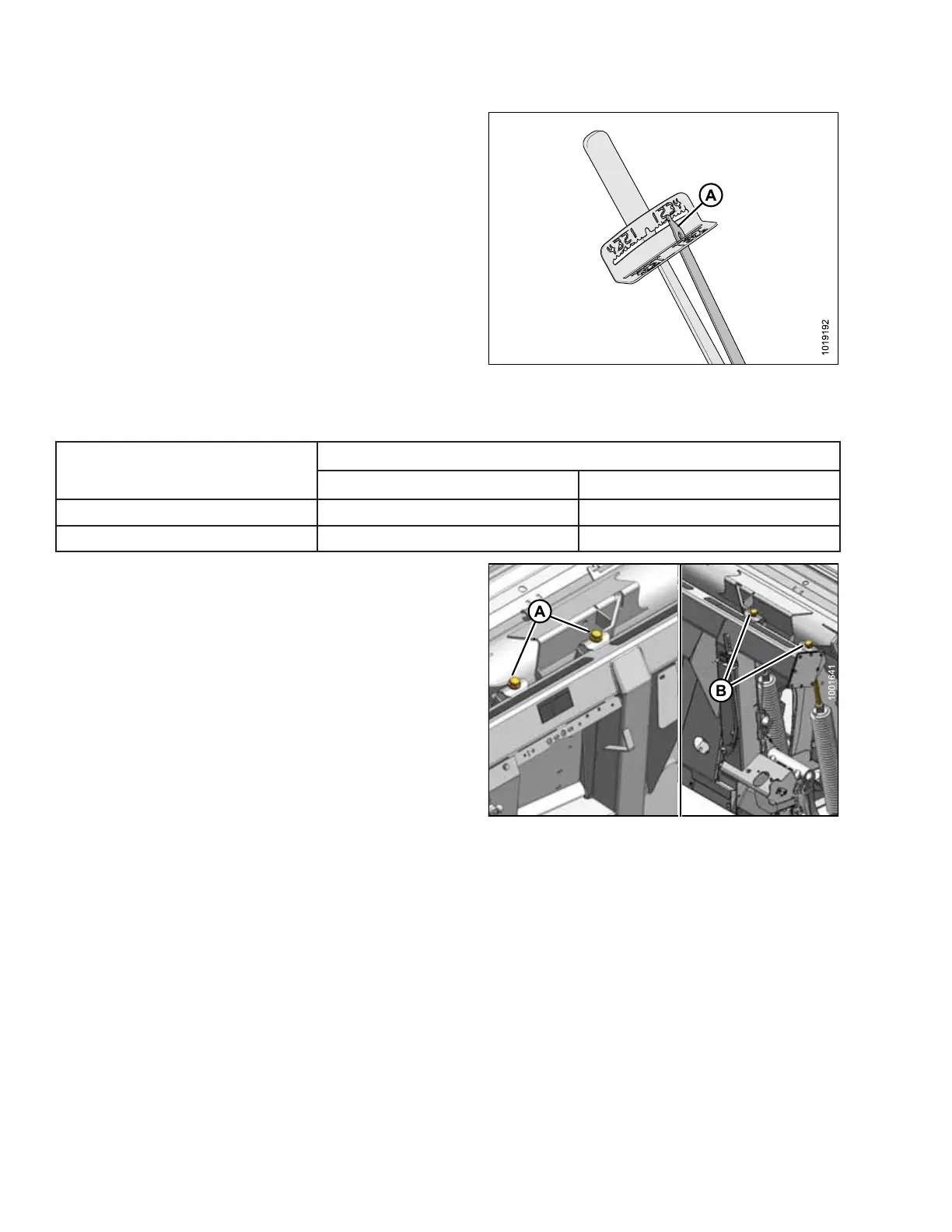

Figure 4.36: Indicator

12. Push down on wrench until indicator (A) reaches a

maximum reading and then begins to decrease. Note

maximum reading and repeat at opposite side.

13. Use following table as a guide for float settings:

• If reading on wrench is high, header is heavy

• If reading on wrench is low, header is light

Table 4.3 Float Settings

Header Size (feet)

Torque Settings

Cutting on Ground Cutting off Ground

30 and 35

1-1/2 to 2 2 to 2-1/2

40 and 45

2 to 2-1/2 2-1/2 to 3

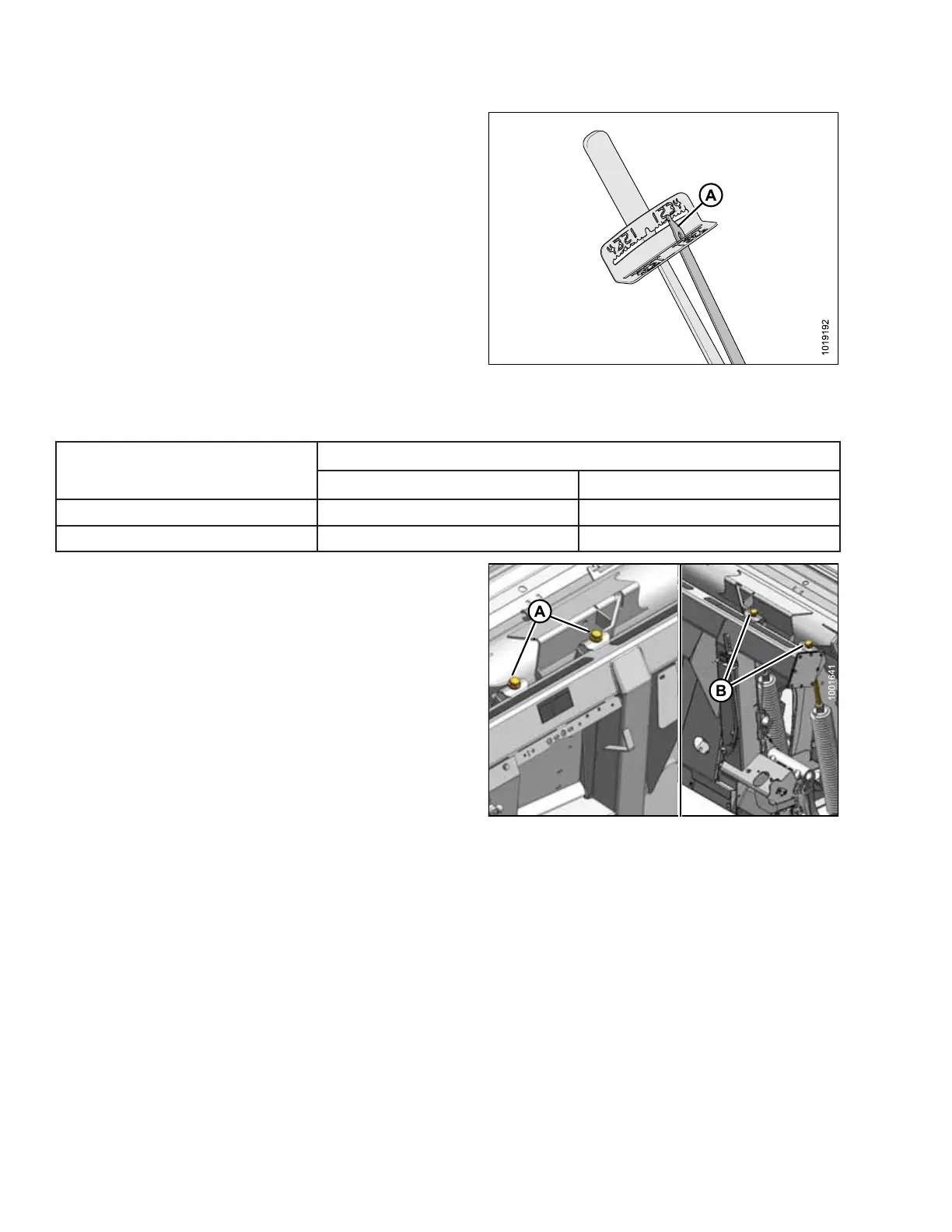

Figure 4.37: Float Adjustment

14. To increase float (decrease header weight)

a. Loosen jam nuts.

b. Turn left adjustment bolts (A) and right adjustment

bolts (B) clockwise.

c. Tighten jam nuts.

15. To decrease float (increase header weight)

a. Loosen jam nuts.

b. Turn left adjustment bolts (A) and right adjustment

bolts (B) counterclockwise.

c. Tighten jam nuts.

16. Use following guidelines when adjusting float:

• Adjust float so wrench readings are equal on both sides of the header.

• For 40- and 45-foot double-knife headers: adjust float so wrench readings are equal at both sides, and

then loosen both right spring bolts two turns.

• Turn each bolt pair equal amounts. Refer to Step 12, page 108, and repeat torque wrench

reading procedure.

NOTE:

If adequate header float cannot be achieved using all of available adjustments, an optional heavy duty spring is

available. Refer to parts catalog for ordering information.

PERFORMING PREDELIVERY CHECKS

Loading...

Loading...