Section 5 – LEGAL INSPECTION

Mini-Crawler Crane M A E D A

5-6 9/2020 MC285CB-3

LEGAL INSPECTION

1. Verify all safety devices are operating

properly.

2. Check the hoist accessories, including the

hook block, for problems or damage.

3. Check the winch wire rope end and wire clip

for damage.

4. Replace the wire rope immediately if

damaged.

5. Check the hydraulic hoses for oil leaks and

damage on the outer surfaces. Replace if any

surface damage is detected.

6. Check the structural parts of the machine,

including the frame and boom, for cracks,

deformation and damage.

7. Check for loose or missing mounting bolts

and joints.

8. Verify the boom operates properly by

stopping, extending, retracting, raising,

lowering and slewing the boom.

Contact us or our sales service agency to request

inspection and repair service as needed.

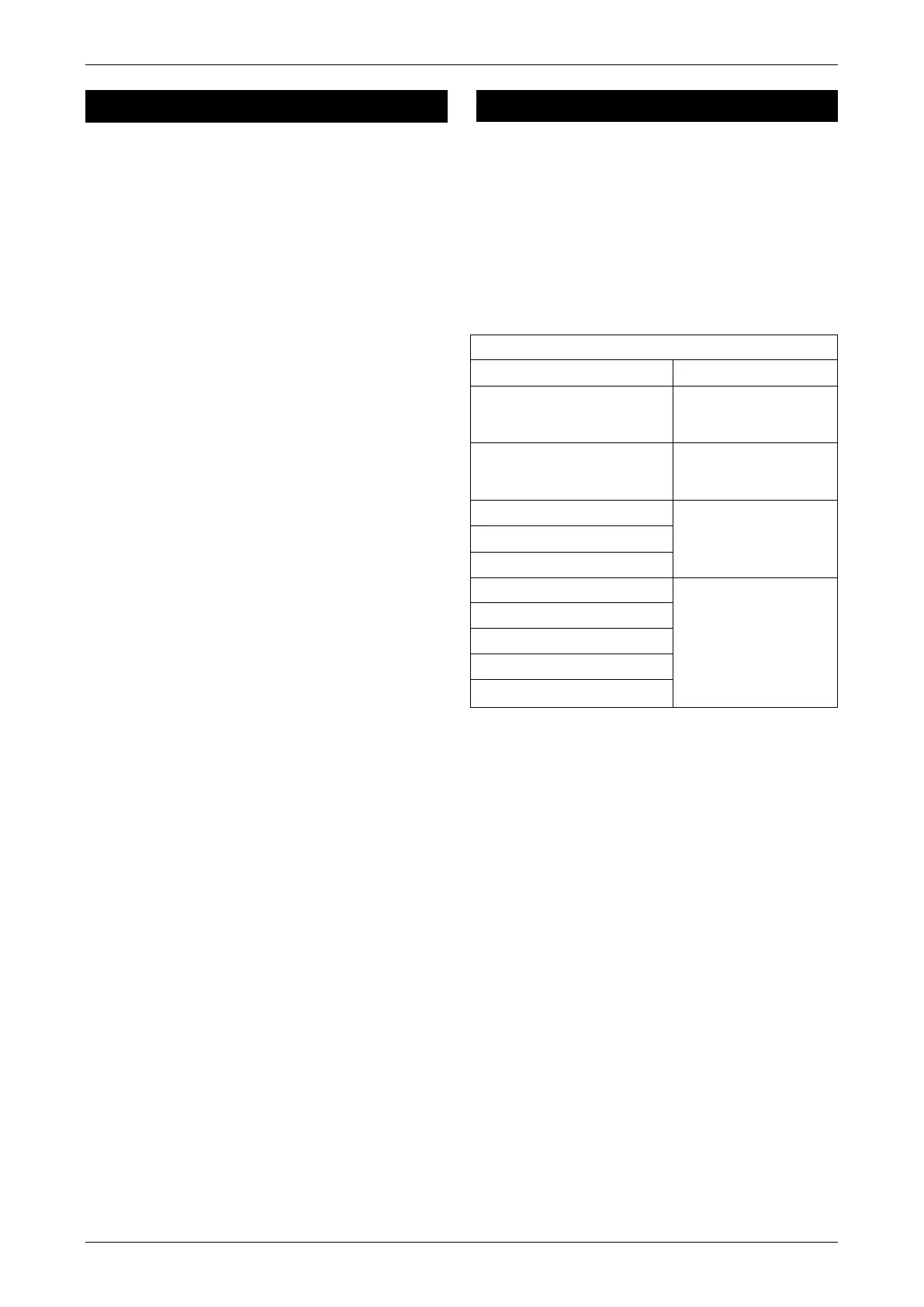

CONSUMABLES

Consumables such as filter elements and wire

ropes are to be replaced at designated periodic

maintenance intervals or prior to reaching their

wear limit. Proper replacement of consumables

ensures increased machine performance and

efficiency.

Always use Maeda genuine parts for part

replacement. See the Maeda genuine parts book

for part numbers when ordering parts.

Hydraulic oil return filter

and then every 500

Hydraulic oil

and then every

Slewing gear oil

After initial 250 hrs

and then every

1,000 hrs

Travel gear oil

Boom slide plate

As required or every

3 years

Winch wire rope

Boom extending wire rope

Boom retracting wire rope

Cylinder packings

The remaining time until replacement of

consumables displayed on the monitor is based

on operating time. Replace items when they are

depleted or worn, even if the indicated

replacement time is not reached.

Loading...

Loading...