Section 5 – TROUBLESHOOTING

Mini-Crawler Crane M A E D A

5-58 9/2020 MC285CB-3

TROUBLESHOOTING

The following troubleshooting charts and procedures are provided to assist in diagnosing problems in the

event of a malfunction or failure.

Contact us or our sales service agency to request inspection and repair services as indicated with a * in

the Actions column, or if you suspect other problems or causes than those given below.

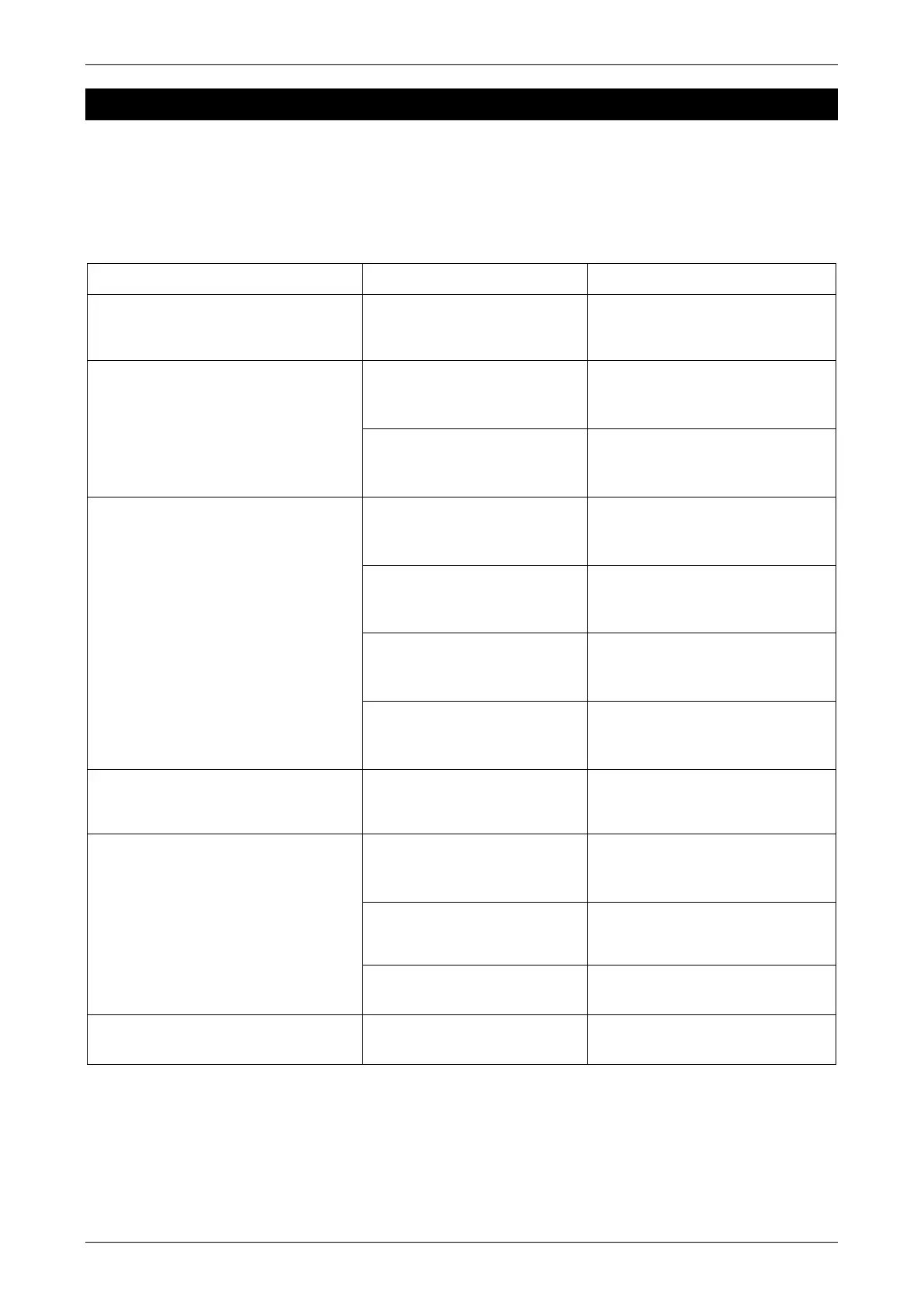

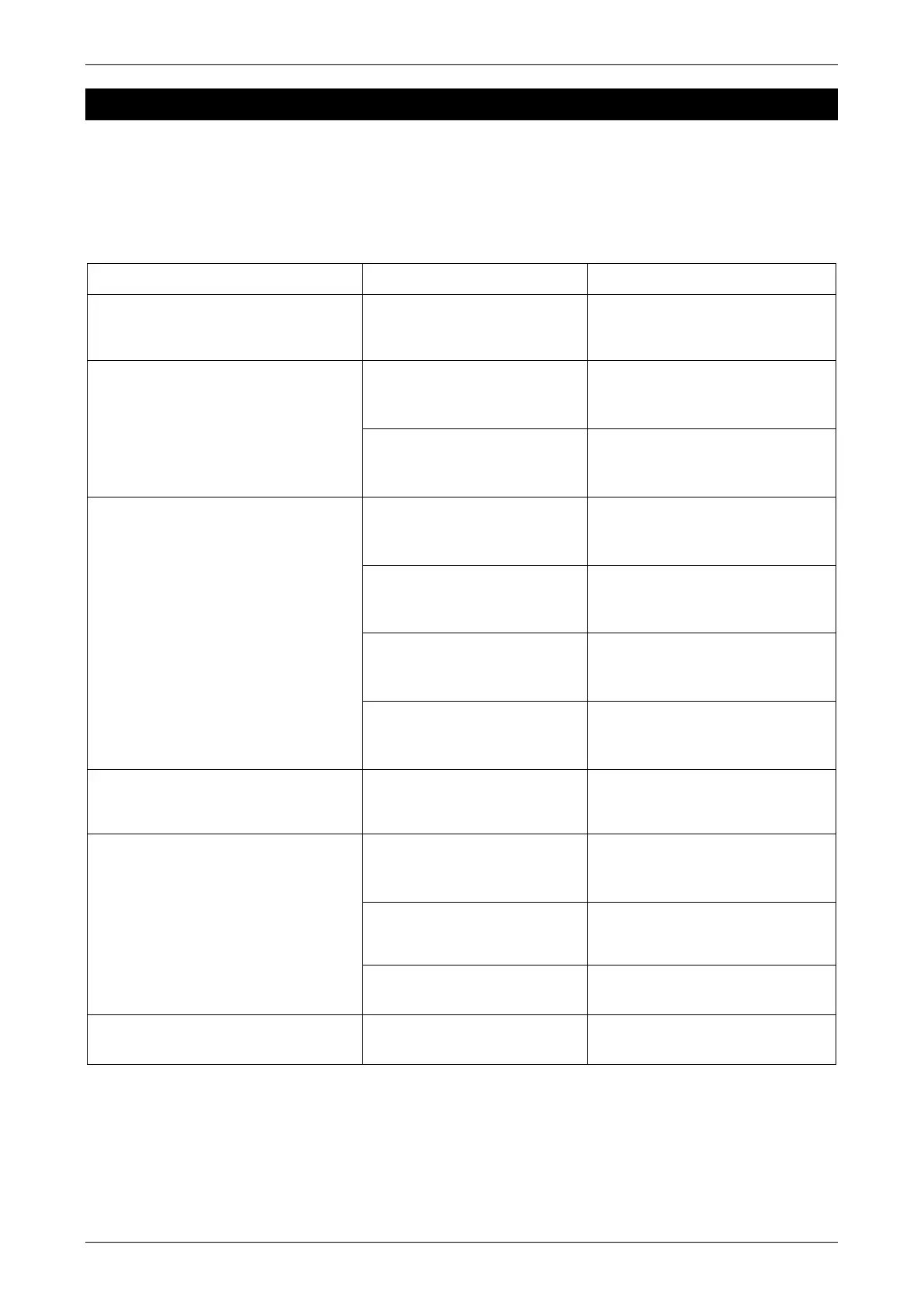

Machine Body

Problem Major Cause(s) Actions

Crane and outriggers do not operate

but machine travels

Travel lever not in

Crane/Outrigger position

Move travel lever to

“Crane/Outrigger”.

Travelling speed, boom and hook

block operation speed slow or

abnormal pump noise

Low hydraulic oil level

Fill hydraulic oil to specified level.

See “Check / Add Hydraulic Oil”

on page 5-16.

Hydraulic oil tank strainer and

element clogged

Clean and replace filter. See

“Replace Hydraulic Oil Return

Filter” on page 5-29.

Hydraulic oil temperature high

Low hydraulic oil level

Fill hydraulic oil to specified level.

See “Check / Add Hydraulic Oil”

on page 5-16.

High working load

Reduce working load.

Increase interval between tasks.

High ambient temperature

Take measures to protect against

high temperatures.

Warming up is turned on. Turn off warming up.

Rubber tracks fall off or abnormal

wear of sprockets

Rubber tracks loose

Adjust track tension. See

“Checking Rubber Track Tension”

on page 5-39.

Outriggers do not operate

Outrigger not rotated to

EXTENSION position

(outward)

Secure the outrigger at the

EXTENSION position.

Travel lever not in

Crane/Outrigger position

Move travel lever to

“Crane/Outrigger”.

Boom is not in stow position

Set (operate) boom in stow

position.

Crane does not operate

Outriggers are not in setting

position

Set (operate) all four outriggers.

Loading...

Loading...