M A E D A Mini-Crawler Crane Section 5 – GENERAL MACHINE MAINTENANCE

9/2020 MC285CB-3 5-41

Wire Rope

General Information and Precautions

Contact us or our sales service agency for

additional information on replacing and repairing

wire rope.

WARNING! Exposure Hazard. Always wear

leather gloves when handling wire rope.

NOTICE: Do not use old wire ropes, even if they

have not been used.

Always use the Maeda genuine wire rope as

specified for the application by Maeda.

Inspecting Wire Rope

Inspect all wire ropes daily before work and

inspect the sheave at the tip of the boom and the

sheave of the hook block. Damaged sheaves

accelerate the damage of the wire ropes. Replace

components immediately if at or beyond the

replacement standard.

The benchmark for replacing wire ropes is

common to all wire ropes for winching,

telescoping the boom and slinging.

Wire rope fatigues with normal use. Change wire

ropes when they show the following signs:

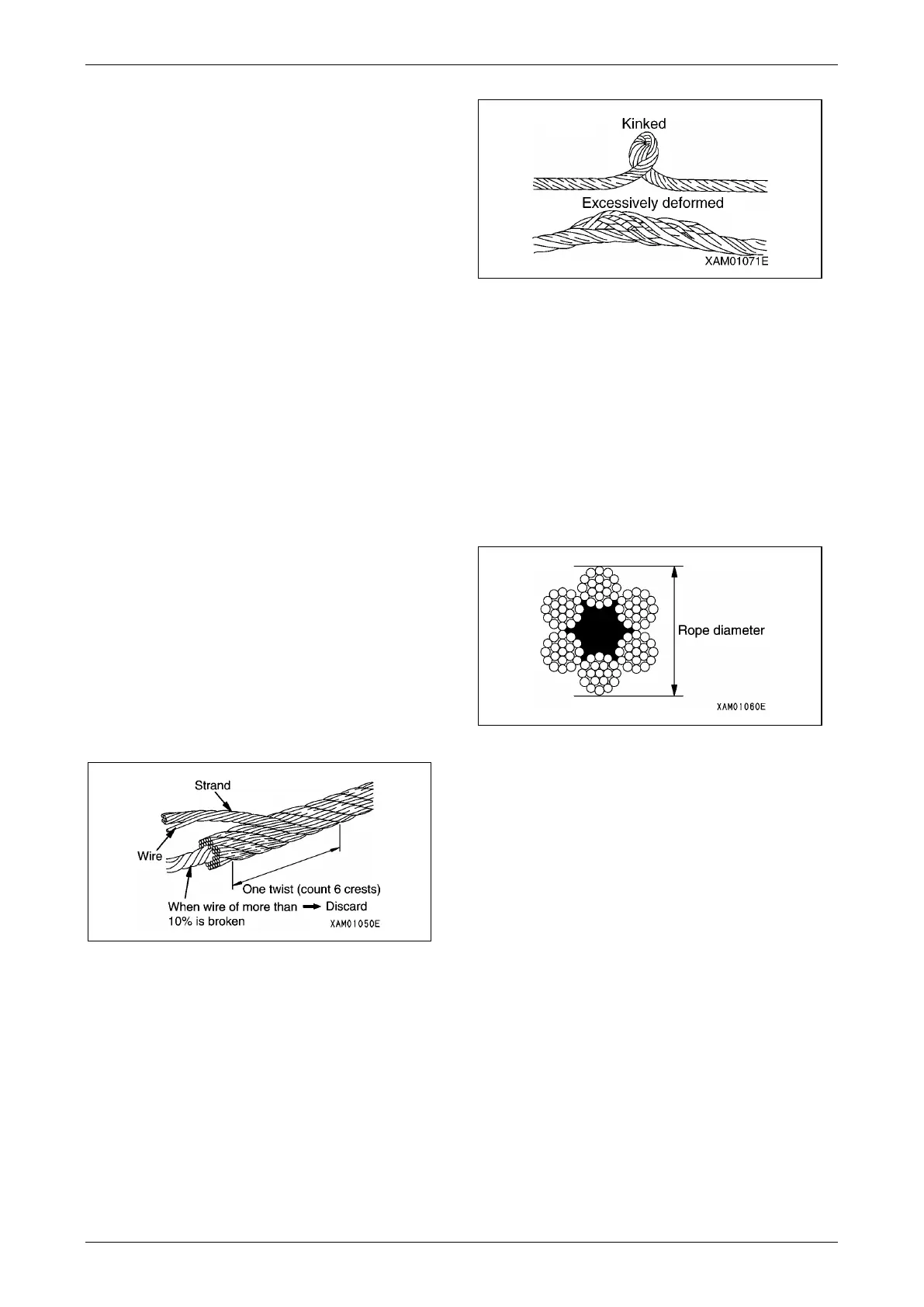

• Broken wire

• In running rope, six randomly distributed broken

wires in one lay or three broken wires in one

strand in one lay

Fig. 5-83

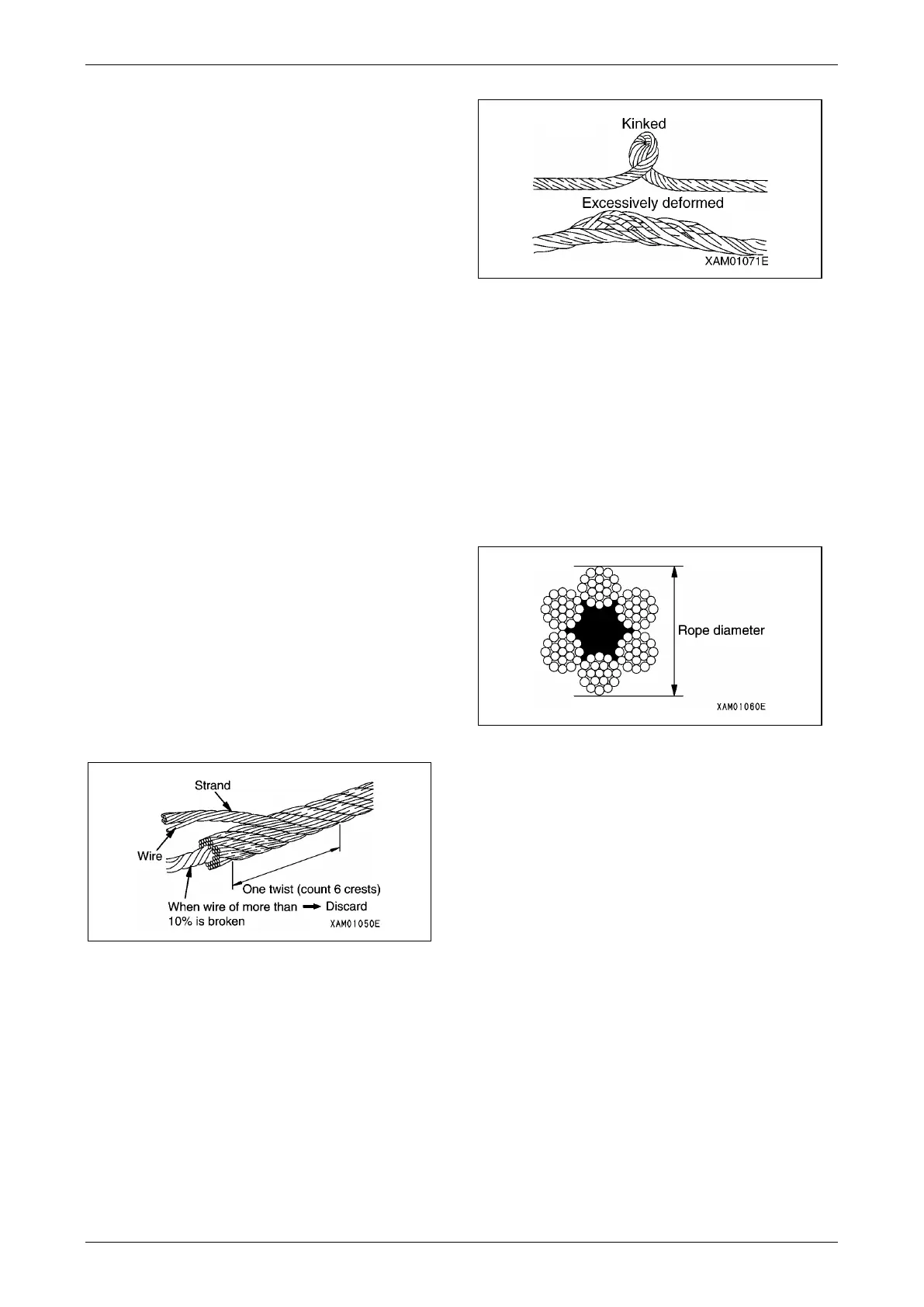

• Kinking, crushing, birdcaging or any other

damage resulting in distortion of the rope

structure

• Evidence of any heat damage

Fig. 5-84

• Wire rope with a diameter of 9 mm should be

replaced when it becomes 8.4 mm.

• Wire rope with a diameter of 8 mm should be

replaced when it becomes 7.5 mm.

• Wire rope with a diameter of 7 mm should be

replaced when it becomes 6.6 mm.

• Wire rope with a diameter of 6 mm should be

replaced when it becomes 5.6 mm.

• Wire rope with a diameter of 5 mm should be

replaced when it becomes 4.7 mm.

Fig. 5-85

Loading...

Loading...