Section 5 – GENERAL MACHINE MAINTENANCE

Mini-Crawler Crane M A E D A

5-40 9/2020 MC285CB-3

8. To confirm that the tension is proper, proceed

with following:

• With the outrigger stowed, ground the

machine. See "OUTRIGGER STOWING"

on page 4-53.

• Let the machine travel back and forth.

• Set up the outrigger and lift the machine

about 80 mm off the ground. See

“OUTRIGGER SETTING” on page 4-43.

9. Again, conduct the rubber track tension

check. If it is not proper yet, repeat the

procedure again.

10. Using the two mounting bolts, reinstall the

inspection cover.

11. Stow the outrigger and lower the machine to

the ground. See "OUTRIGGER STOWING"

on page 4-53.

In case the tension is strong (to reduce

tension)

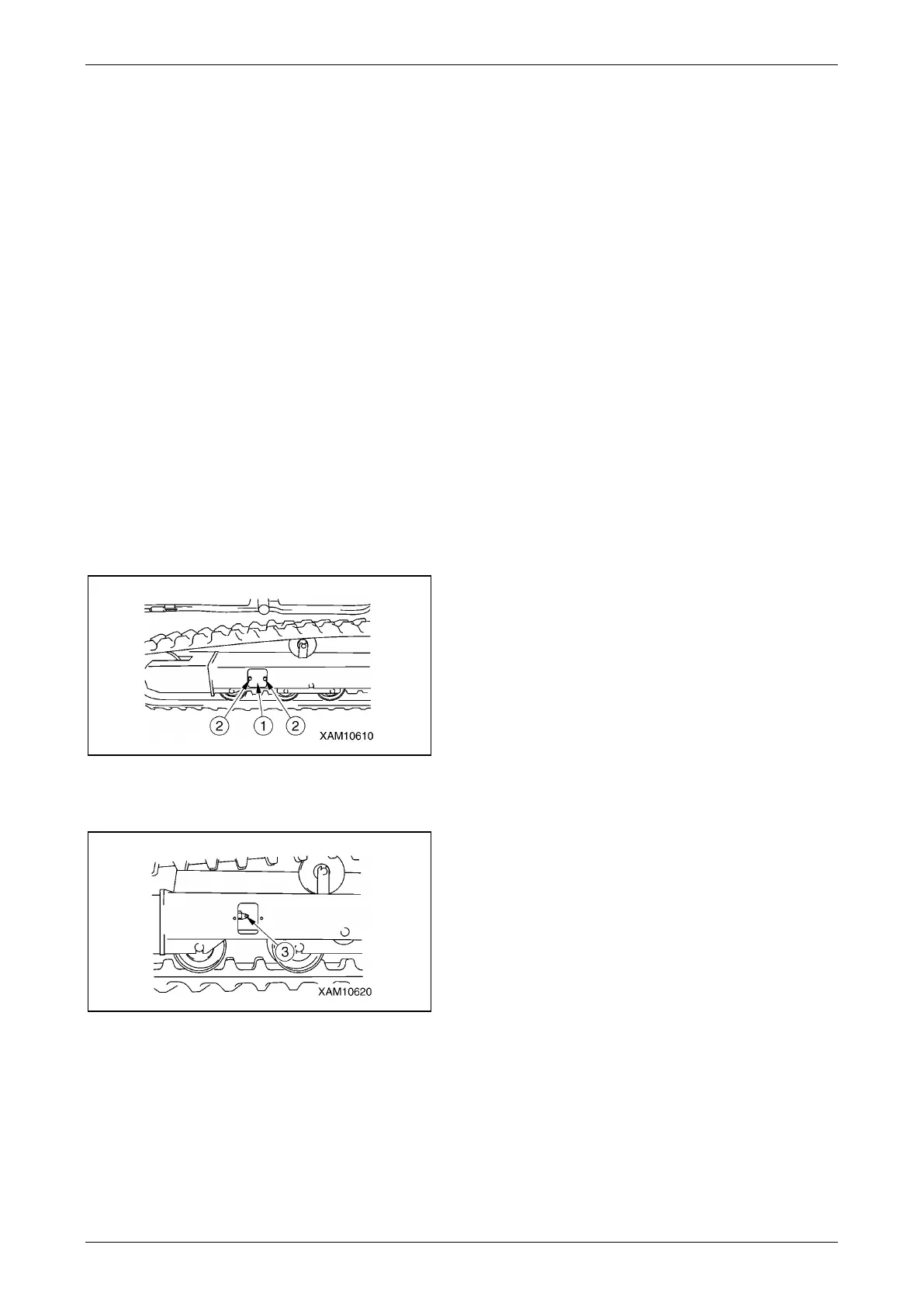

1. With two mounting bolts (2) removed, remove

the inspection cover (1).

Fig. 5-81

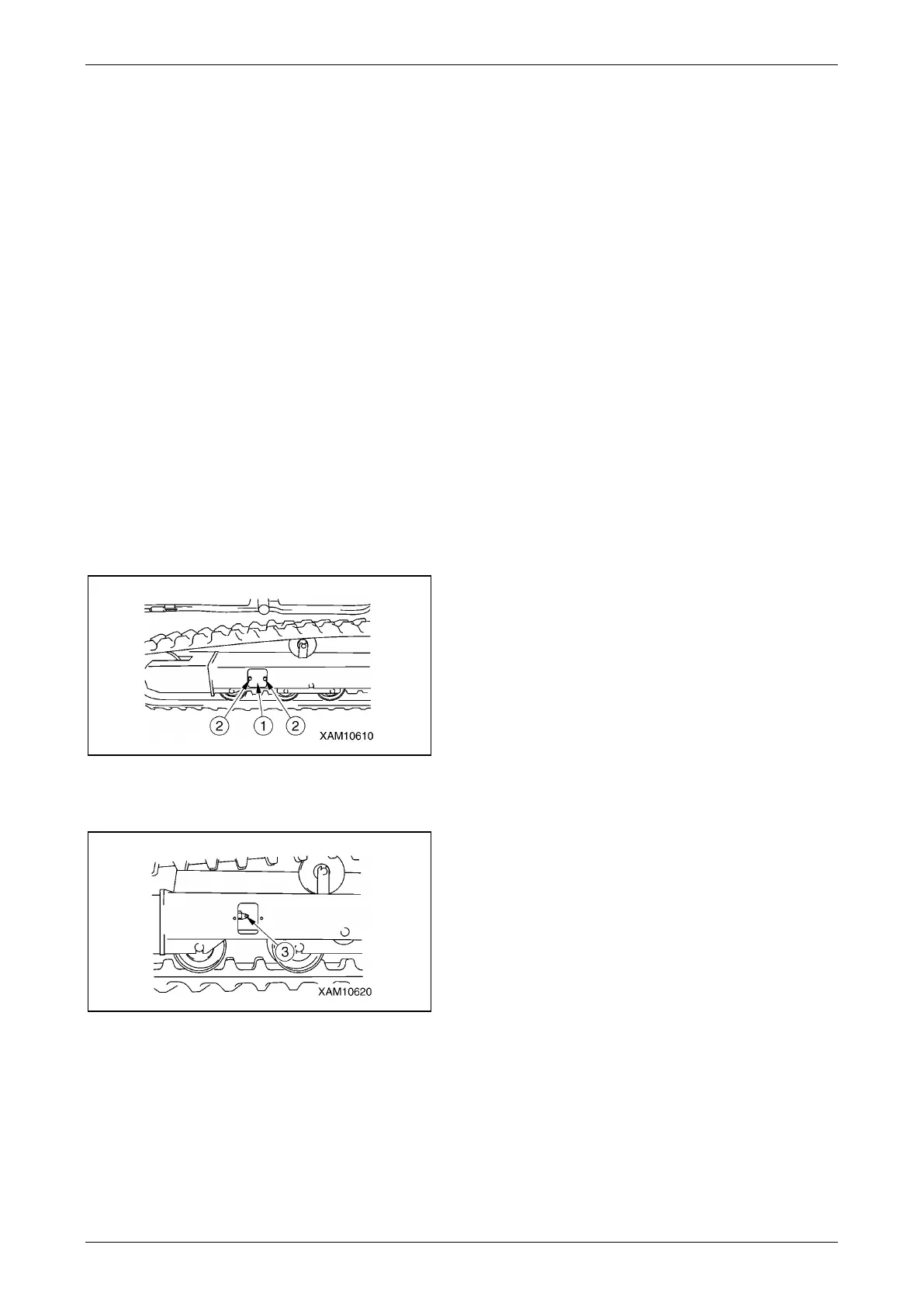

2. Loosen grease valve (3) slowly to let the

grease come out.

Fig. 5-82

3. Use care not to loosen the grease valve by

more than one turn.

4. If the grease does not come out smoothly,

take following measures:

a. Stow the outrigger and lower the machine

to the ground. See "OUTRIGGER

STOWING" on page 4-53.

b. Move the machine back and forth.

c. Set up outrigger and lift the undercarriage

off the ground about 80 mm. See

“OUTRIGGER SETTING” on page 4-43.

5. Tighten the grease valve).

6. Conduct the rubber crawler tension check. If

the tension is still improper, repeat the

adjustment again.

7. Using the two mounting bolts, reinstall the

inspection cover.

8. Stow the outrigger and lower the machine to

the ground.

Loading...

Loading...