M A E D A Mini-Crawler Crane Section 5 – GENERAL MACHINE MAINTENANCE

9/2020 MC285CB-3 5-51

Drain Water and Sediment Inside

Hydraulic Oil Tank

WARNING! Parts will still be hot immediately

after the machine has been operating. Do not

change the oil immediately, but wait until the

oil has cooled.

Oil may spray out when removing the air

breather cap on the hydraulic oil tank.

Unscrew the cap slightly to relieve the internal

pressure before removing it.

Tighten the cap securely after replenishing

the oil. If not fully tightened, the cap may come

loose and fall off during operation, potentially

causing burn injuries if hot oil spurts out.

CAUTION: See “LUBRICATING OIL” on page

5-7 for the oil to be used.

Be sure to arrange the machine in its

travelling posture when checking the oil level.

Checking the oil level while in the working

posture will result in overfilling, as the oil level

will be underestimated.

After replacing the hydraulic oil, do not start

the machine for a while until the pipes and

hydraulic equipment are filled with oil.

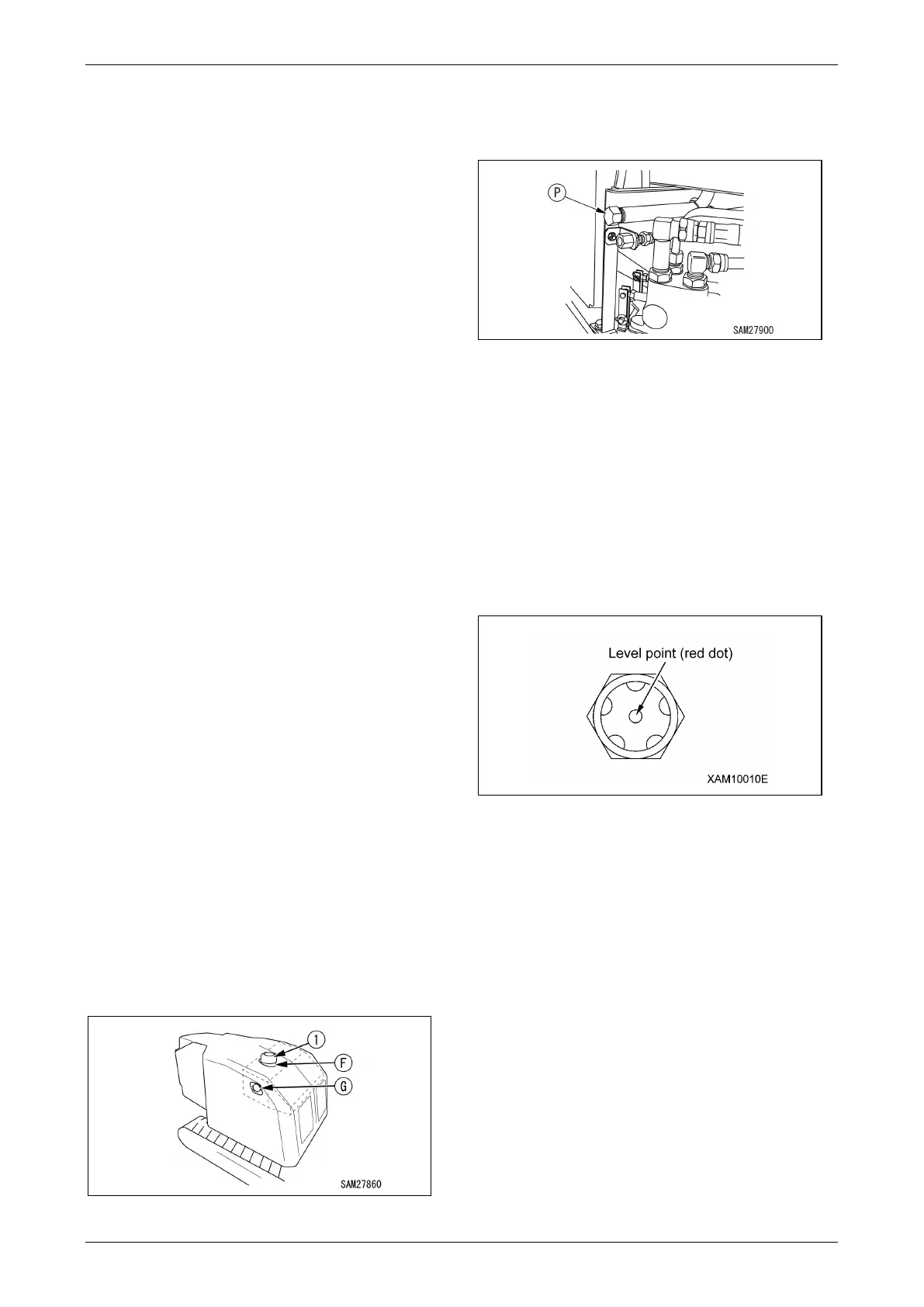

Do not fill with oil above the level point (red

dot) on the level gauge (G).

Be careful to avoid allowing any foreign

matter into the oil inlet opening when

replenishing the oil.

Container to catch contaminating water: Prepare

a container with a capacity of at least 5 L.

1. Stop the machine on a level surface.

2. See “TRAVELLING POSITION” on page 4-29

and put the machine in the “Travelling

posture”.

3. See “Removing Machinery Cover” on page

5-11 and remove the machinery cover.

4. See “Air Breather Inspection” on page 5-49

and remove the air breather cap (1) from the

oil inlet (F) on the top of the hydraulic oil tank.

Fig. 5-116

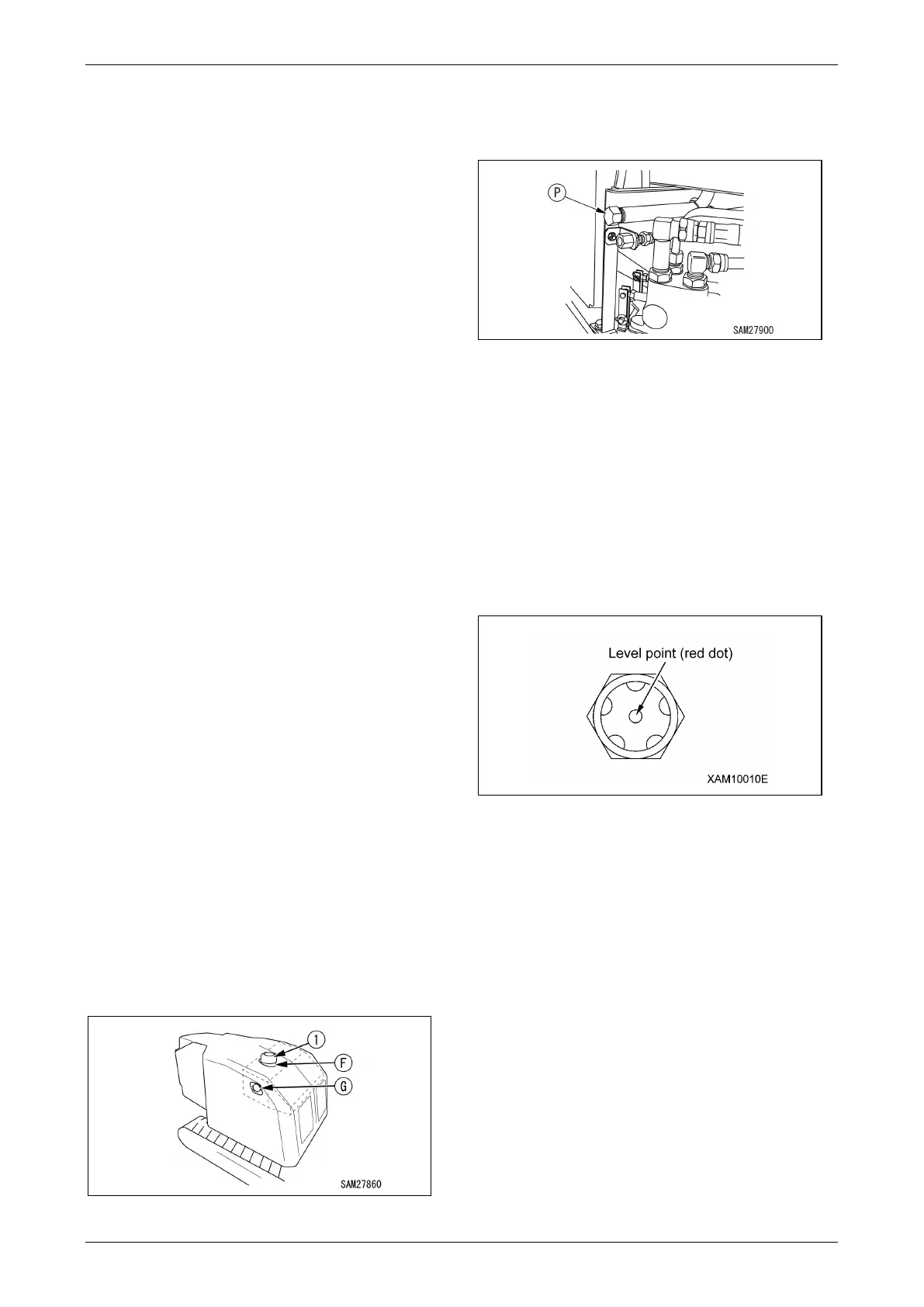

5. Place the container to catch the

contaminating water immediately below the

drain outlet cap (P).

Fig. 5-117

6. Slowly rotate the drain outlet cap (P) to avoid

splashing oil or water on yourself, and drain

the contaminating water.

7. If the drained contaminating water is found to

contain large amounts of metal particles or

other foreign matter when inspected, contact

us or our sales service agency.

8. Reattach the drain outlet cap (P).

9. Replenish the hydraulic oil via the oil inlet (F)

up to the level point (red dot) while watching

the oil level gauge (G).

10. After replenishing the oil, see “Air Breather

Inspection” on page 5-49 and securely

reattach the air breather cap (1) on the oil

inlet (F).

11. See “Installing Machinery Cover” on page

5-11 and install the machinery cover.

Loading...

Loading...