Section 5 – INSPECTION

Mini-Crawler Crane M A E D A

5-16 9/2020 MC285CB-3

Check Fuses

NOTICE: If fuses blow frequently, inspect and

repair the cause of failure immediately before

continuing operation.

See “FUSES” on page 5-12 for more information

on fuse locations.

If a fuse has blown or an open/short circuit is

found in the electrical wiring, contact us or our

sales service agency to request inspection and

repair service.

Check Cracks, Deformation or Damage

of Boom and Frame

Check the boom and frame for cracks,

deformation or any other damage, and correct

them if anything abnormal is found.

Check Deformation, Damage or Wear of

Wire Rope

Check the rope end fixing, rope take up condition

and contact between the ropes. For the check and

inspection of wire rope while winch and boom

telescoping, see “Wire Rope” on page 5-41.

Check Electric Wiring

Check the electric wiring and inspect to ensure

that wiring has not been disconnected, damaged,

or burnt out, and that connectors are not

disconnected.

Pre-Start Inspection

Check / Add Hydraulic Oil

Before checking or adding hydraulic oil, read the

maintenance precautions in “Handling and

Service of Hydraulic Oil and Filters” on page 5-4.

WARNING! The following safety messages

address a potential Burn Hazard:

• Parts will still be hot immediately after

stopping machine operation. Do not carry

out work immediately. Wait until the oil has

cooled. (45°C or less)

• Relieve internal pressure by slowly rotating

the hydraulic tank air breather cap during

removal.

• Make sure the hydraulic tank air breather

cap is closed properly after adding oil.

• When filling the hydraulic oil tank, do not fill

above the upper limit on the level gauge.

Overfilling may cause oil to gush from the

tank during machine operation.

If the tank interior is still pressurized when the air

breather cap is removed, the element may be

clogged. Inspect the air breather.

For information on the air breather inspection, see

“Air Breather Inspection” on page 5-49.

1. Stop the machine on a level surface in the

travelling posture.

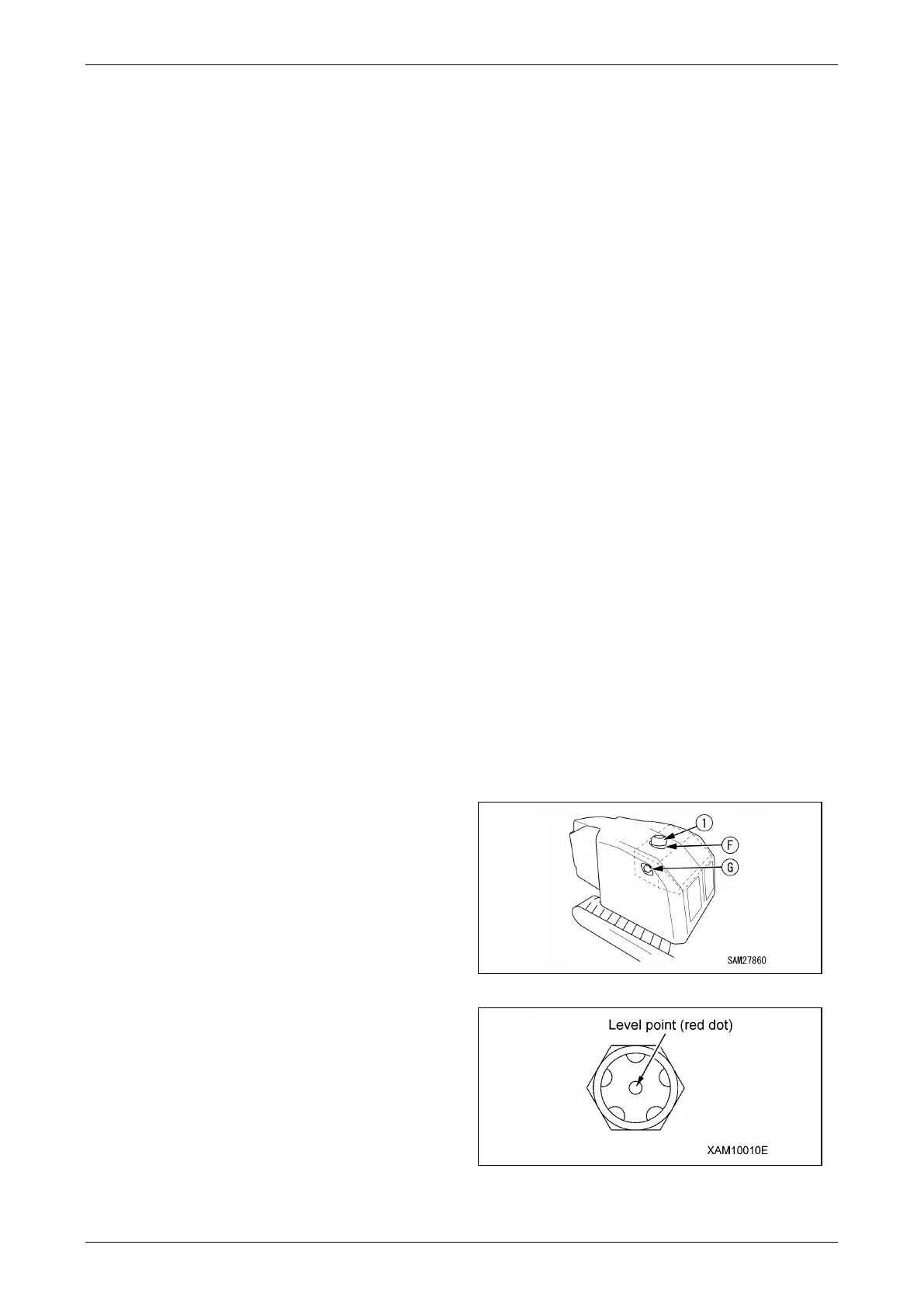

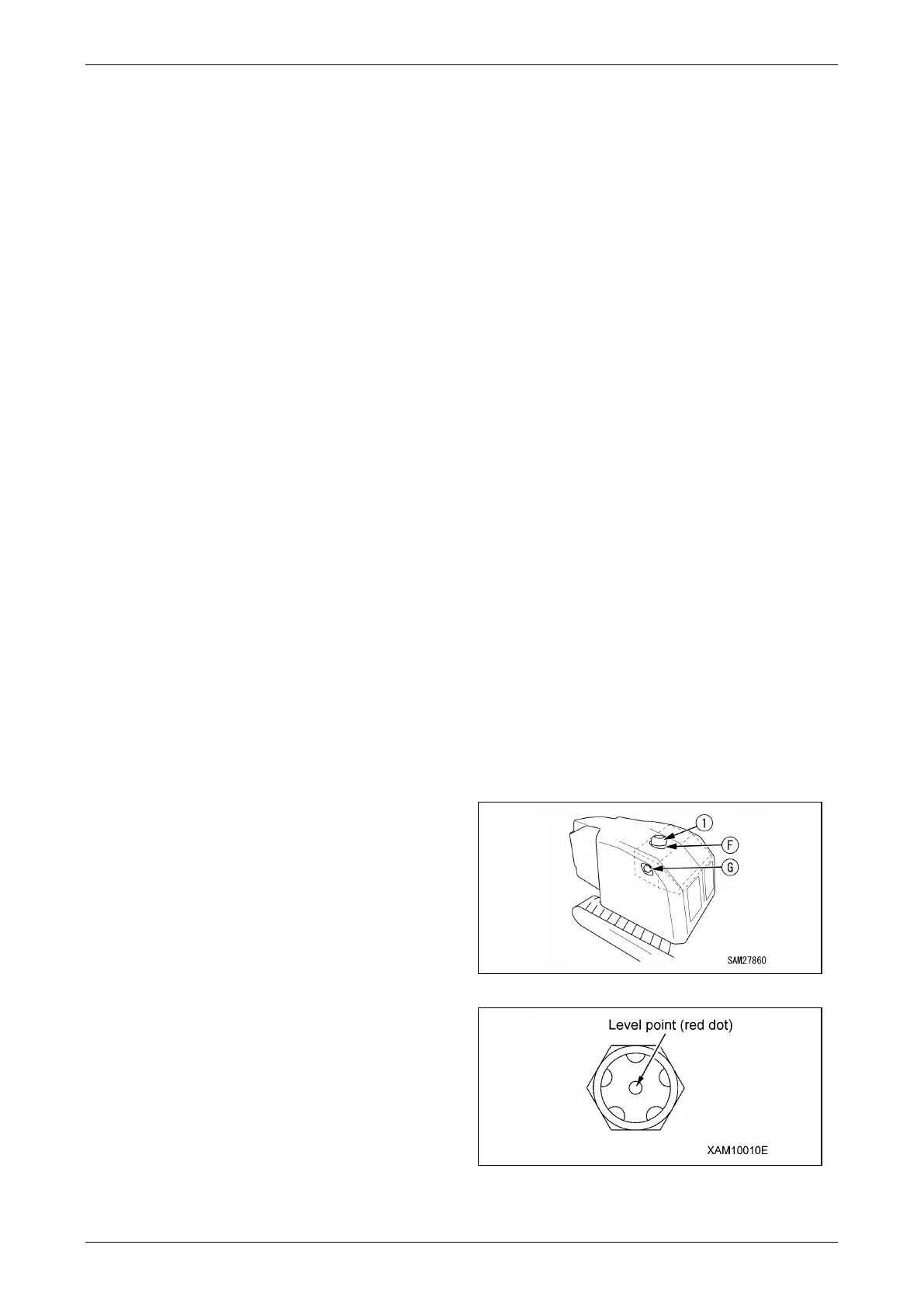

2. Check the oil level gauge (G) in the left side of

the machinery cover and ensure that oil is

sufficient to reach the level point (red point).

Fig. 5-9

Fig. 5-10

Loading...

Loading...