Section 5 – PERIODIC MAINTENANCE

Mini-Crawler Crane M A E D A

5-30 9/2020 MC285CB-3

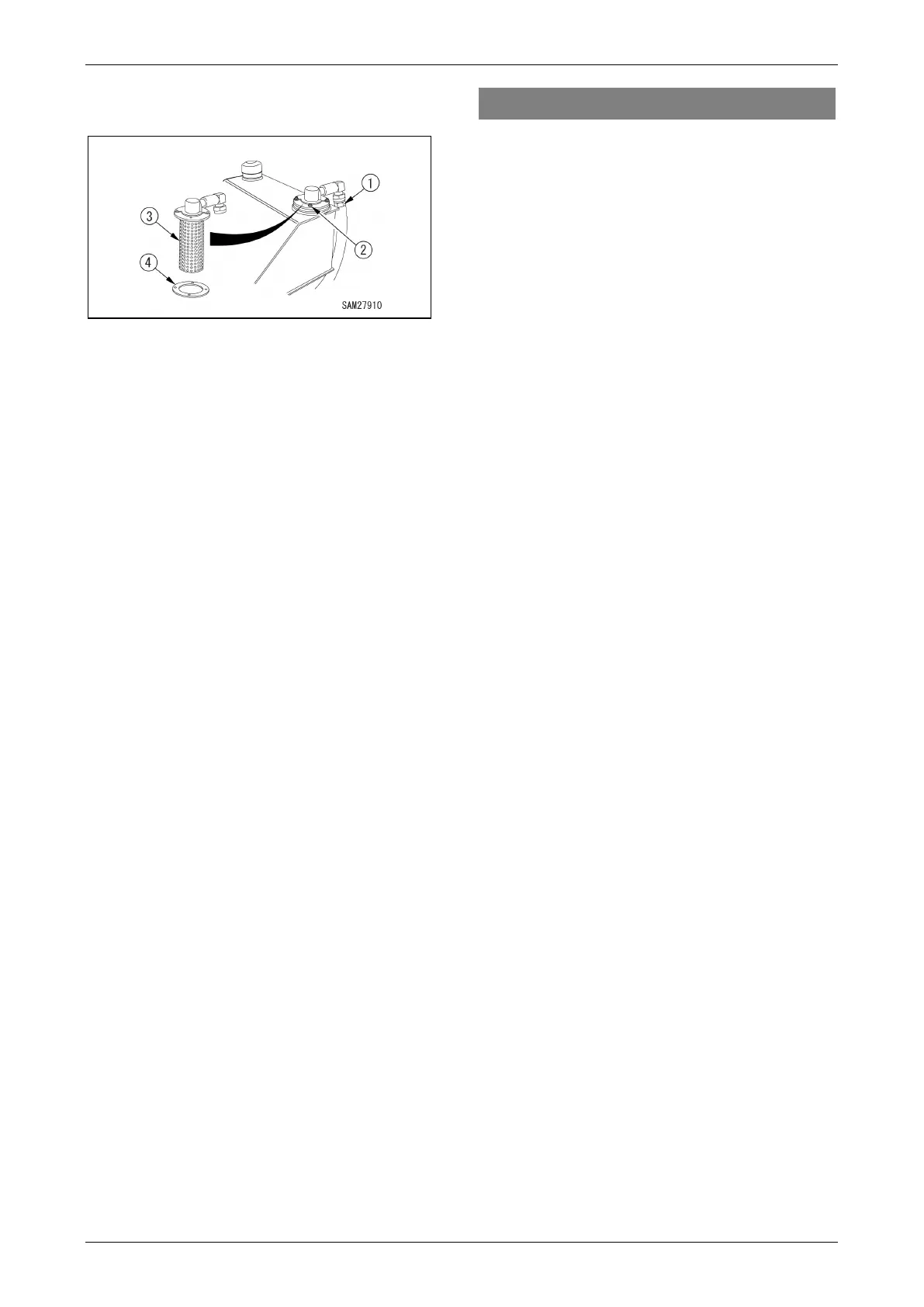

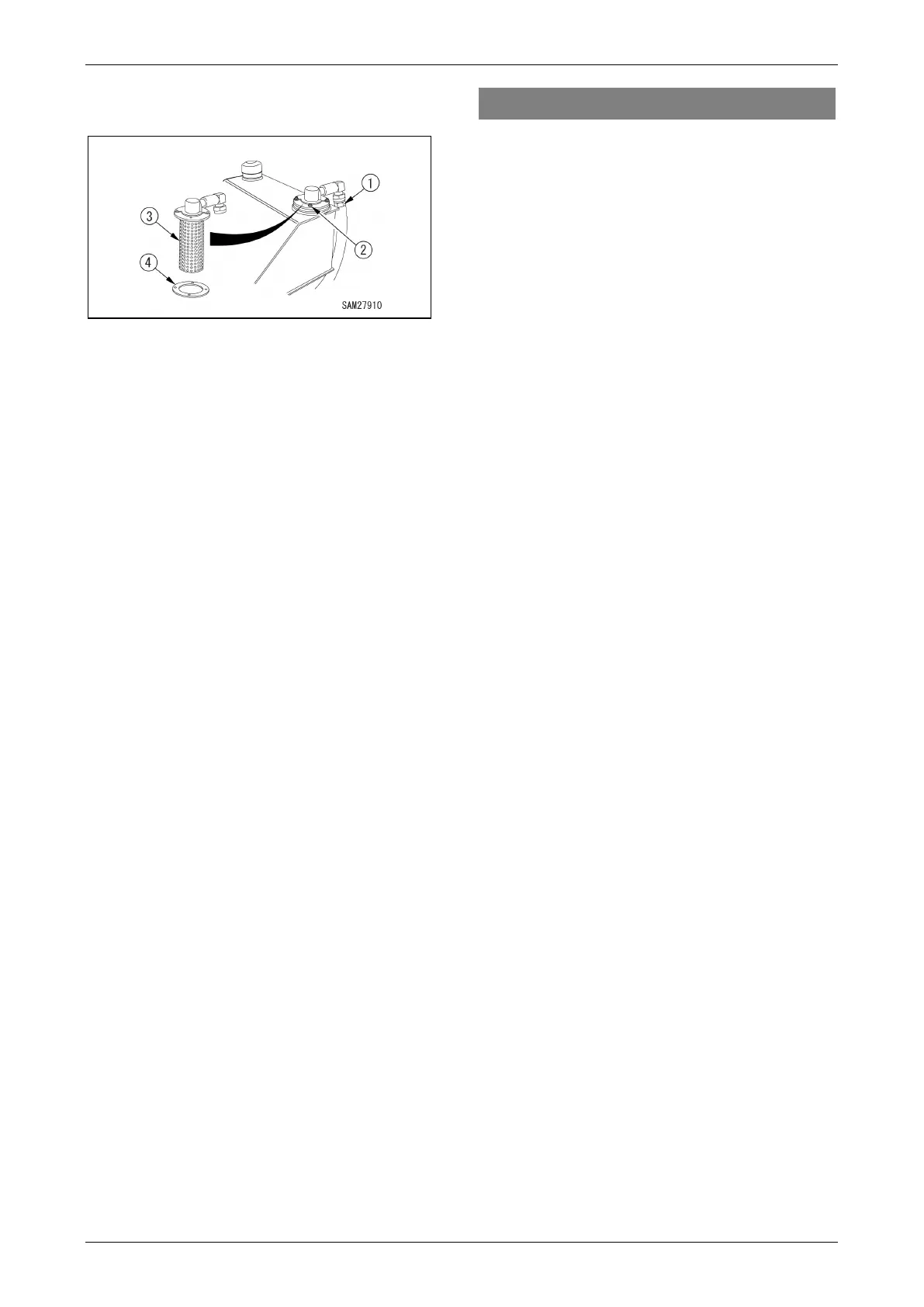

4. Remove the hose (1) and elbow joint from the

return filter (3).

Fig. 5-39

5. Remove the mounting bolts (2) (4 bolts) and

lift the return filter to pull it out.

6. Apply liquid packing to the rubber plate (4),

mount a new hydraulic oil return filter and

securely tighten the mounting bolts (4 bolts).

7. Reinstall the hose and elbow joint removed in

step 4.

8. See “Check / Add Hydraulic Oil” on page 5-16

and replenish the hydraulic oil.

9. See “Installing Machinery Cover” on page

5-11 and install the machinery cover.

10. Bleed the air according to the following

sequence.

a. Wait until the pipes and hydraulic

equipment are filled with oil before starting

the machine.

b. While keeping the motor speed low,

slightly operate each crane control lever to

operate each cylinder and winch motor

slowly.

Do not operate the boom hoisting cylinder

and telescopic boom cylinder to the stroke

end, but stop them at a position

approximately 100 mm before the stroke

end.

Repeat this 4 to 5 times.

c. Extend the outriggers and make the

outrigger cylinders telescope in the

condition that the machine does not float.

When making the outrigger cylinder

telescope, do not operate it to the stroke

end, but stop it at a position approximately

100 mm before the stroke end.

Repeat this 4 to 5 times.

Maintenance Every 1000 Hours

Replace Oil in Hydraulic Oil Tank

WARNING! Various parts are at elevated

temperatures immediately after machine

operation. Do not change the oil immediately.

Wait until the oil is cooled. (Oil temperature

45°C or lower)

WARNING! Oil may spray out when removing

the air breather cap on the hydraulic oil tank.

Unscrew the cap slightly to relieve the internal

pressure before removing it.

WARNING! Tighten the cap securely after

replenishing the oil. If not fully tightened, the

cap may come loose and fall off during

operation, potentially causing burn injuries if

hot oil spurts out.

CAUTION: See “LUBRICATING OIL” on page

5-7 for the oil to be used.

CAUTION: Be sure to put the machine in the

travelling posture when checking the oil level.

If you check the oil level in the working

posture, you judge the oil level to be low and

feed the oil excessively.

CAUTION: After replacing the hydraulic oil, do

not start the machine for a while until piping

and hydraulic equipment are filled with the oil.

CAUTION: Avoid the oil exceeding the level

point (red point) of the level gauge.

When the oil goes beyond the correct level, it

may spout out from the air breather during

travelling or crane operation.

Be careful not to let any foreign substance go

into the filler opening when refilling the oil.

• Oil drain pan: Prepare a container of at least

25 L.

• Quantity of oil in hydraulic oil tank for

replacement: 20 L

1. Place the machine on a level surface.

2. See “TRAVELLING POSITION” on page 4-29

and put the machine in the “Travelling

posture”.

3. See “Removing Machinery Cover” on page

5-11 and remove the machinery cover.

Loading...

Loading...