M A E D A Mini-Crawler Crane Section 5 – PERIODIC MAINTENANCE

9/2020 MC285CB-3 5-31

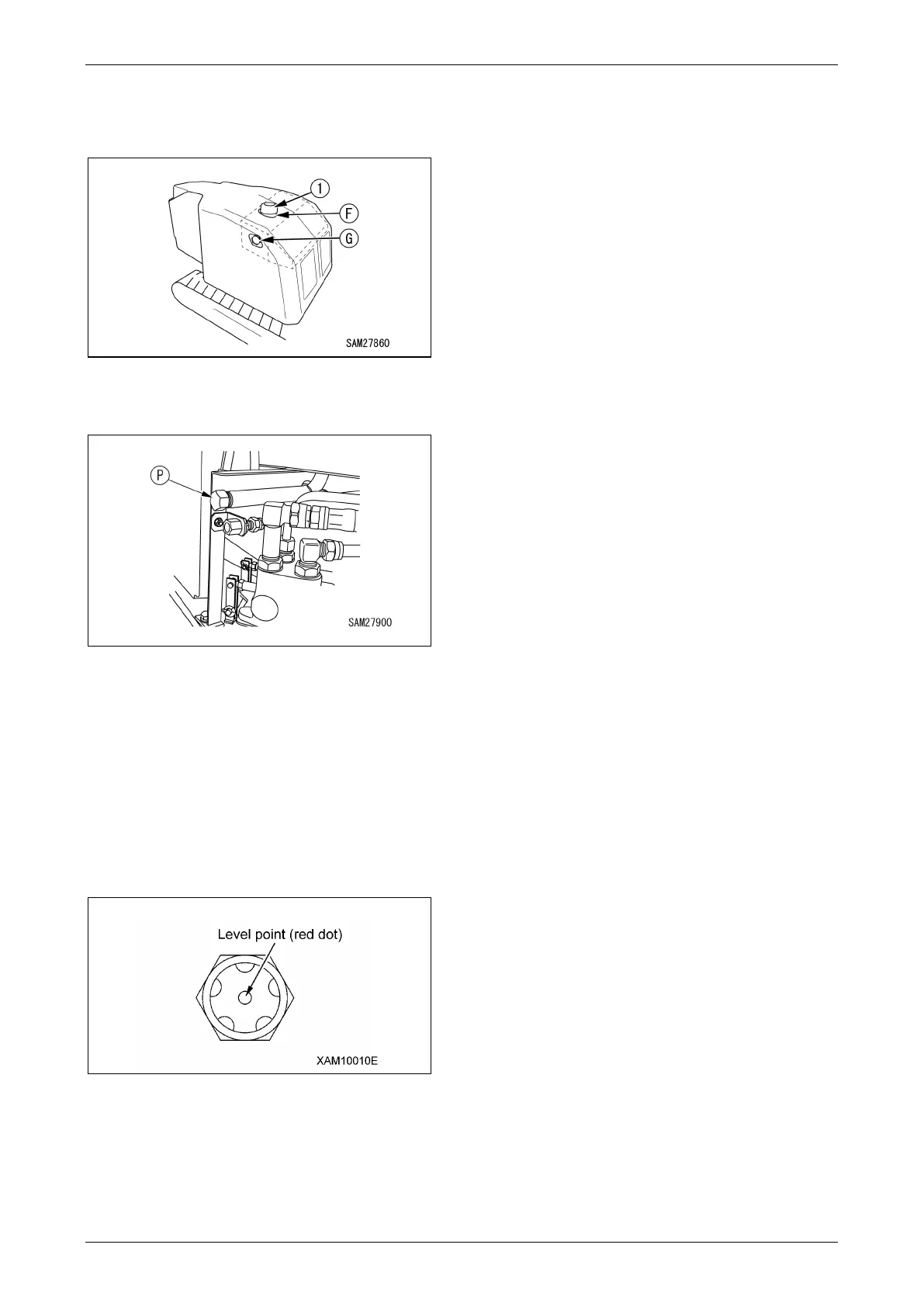

4. See “Air Breather Inspection” on page 5-49

and remove the air breather cap (1) from the

oil inlet (F) on the top of the hydraulic oil tank.

Fig. 5-40

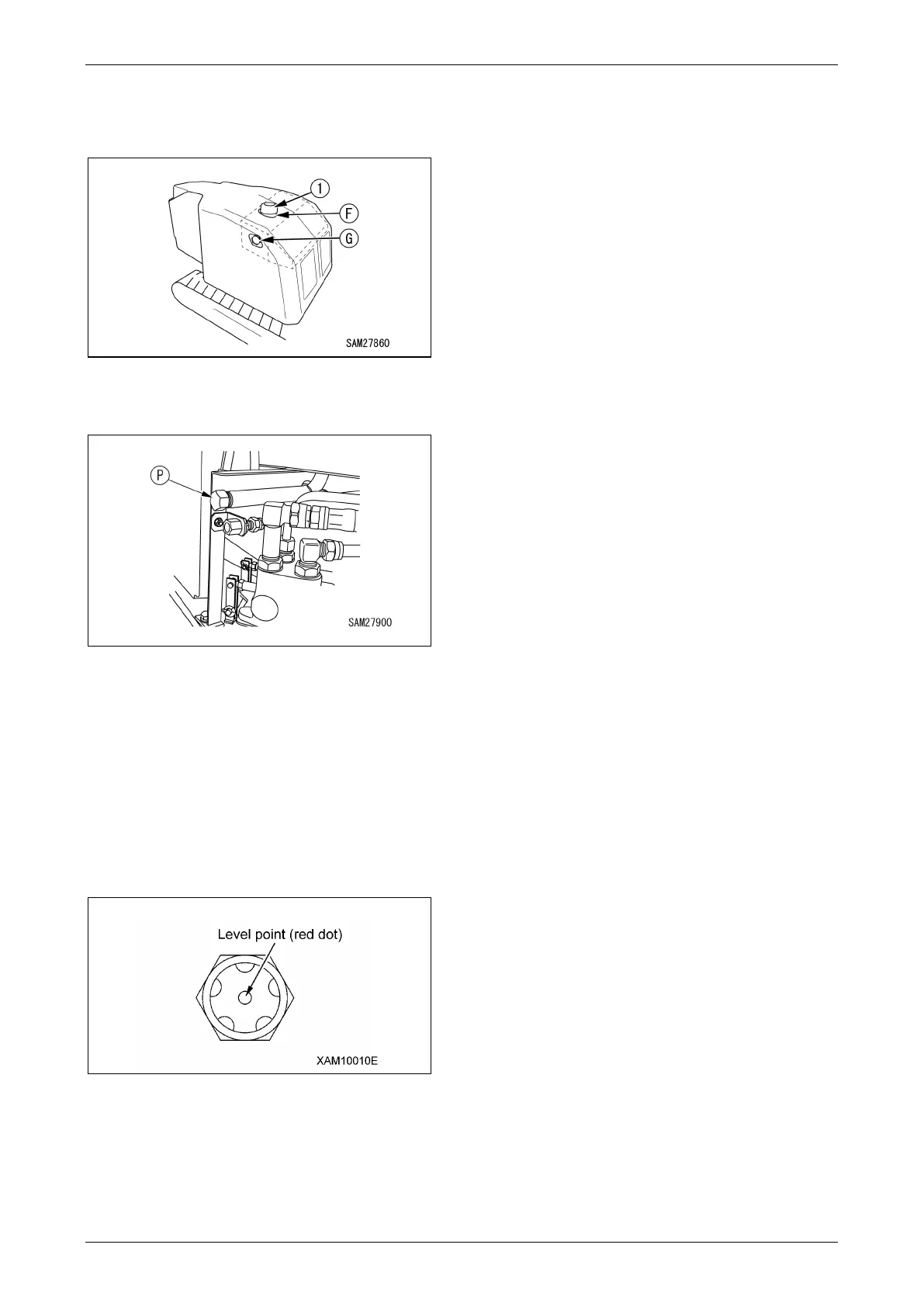

5. Place a drain pan directly underneath the

drain port cap (P) to receive drained oil.

Fig. 5-41

6. Remove the drain port cap slowly to drain the

oil, keeping from contact with draining oil.

7. Check the drained oil and if it contains an

unacceptable amount of metal particles or

foreign matter, contact our sales service

agency.

8. Install the drain port cap.

9. Feed hydraulic oil through the filler port to the

level point (red dot) while looking at the oil

level gauge.

Fig. 5-42

10. After replenishing the oil, see “Air Breather

Inspection” on page 5-49 and securely

reattach the air breather cap (1) on the oil

inlet (F).

11. See “Installing Machinery Cover” on page

5-11 and install the machinery cover.

12. Bleed the air according to the following

sequence.

a. Wait until the pipes and hydraulic

equipment are filled with oil before starting

the machine.

b. While keeping the motor speed low,

slightly operate each crane control lever to

operate each cylinder and winch motor

slowly.

Do not operate the boom hoisting cylinder

and telescopic boom cylinder to the stroke

end, but stop them at a position

approximately 100 mm before the stroke

end.

Repeat this 4 to 5 times.

c. Extend the outriggers and make the

outrigger cylinders telescope in the

condition that the machine does not float.

When making the outrigger cylinder

telescope, do not operate it to the stroke

end, but stop it at a position approximately

4 in. (100 mm) before the stroke end.

Repeat this 4 to 5 times.

Loading...

Loading...