Section 5 – GENERAL MACHINE MAINTENANCE

Mini-Crawler Crane M A E D A

5-38 9/2020 MC285CB-3

A steel pipe is required for the following

procedure.

1. Set the outriggers and raise the tracks

approximately 50 mm from the ground. See

“OUTRIGGER SETTING” on page 4-43.

2. Remove the two screws (2) and cover plate

(1).

Fig. 5-70

3. Loosen the grease valve (3) slowly and

remove grease. Do not turn the grease valve

more than one full turn out.

Fig. 5-71

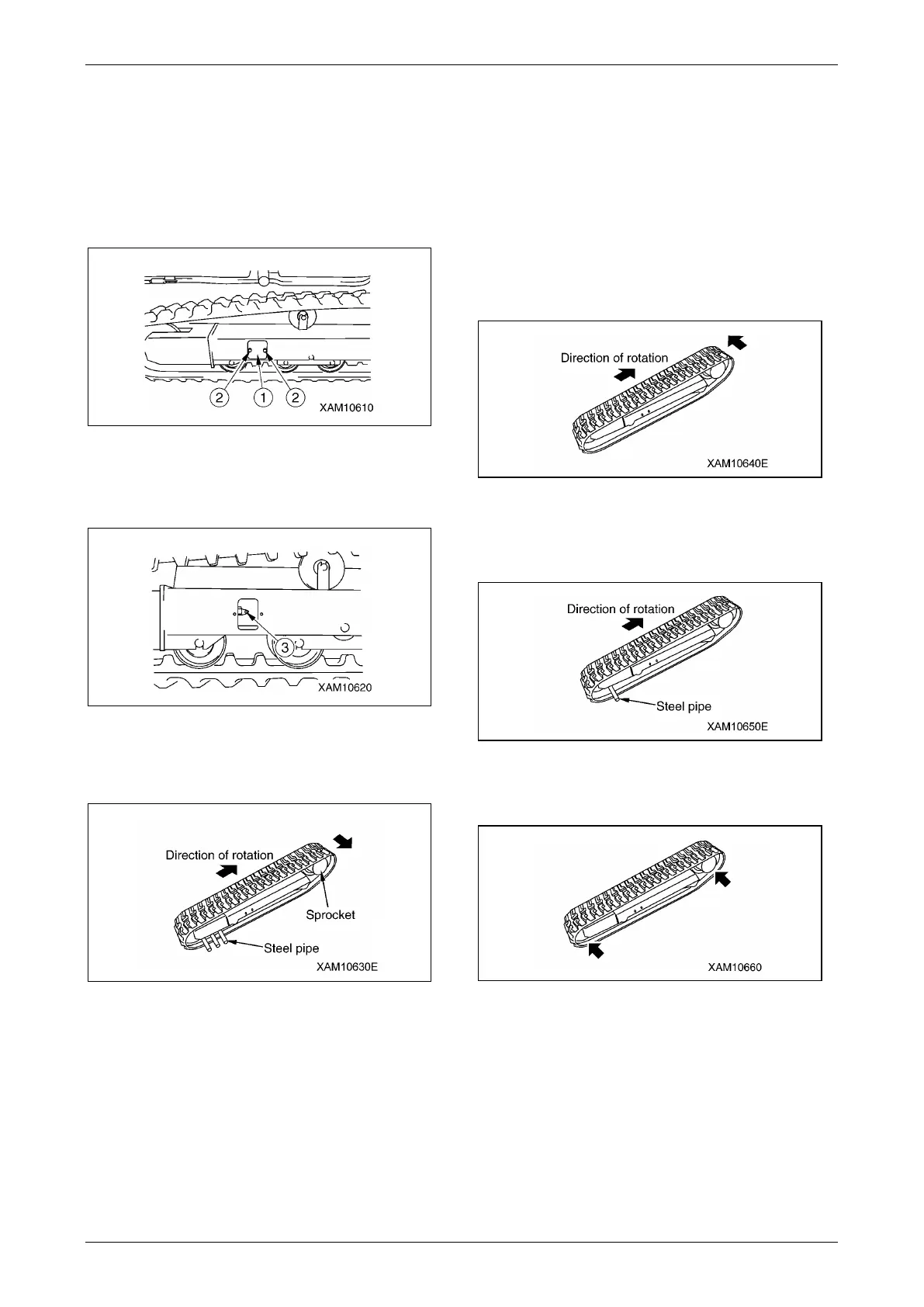

4. Insert the steel pipe between the idler and

rubber track, as shown below, and rotate the

sprocket backward.

Fig. 5-72

5. After the rubber track is free from the idler,

slide the crawler in a lateral direction to

remove it.

Installation of Rubber Tracks

A grease gun and steel pipe are required for the

following procedure.

1. Set the outriggers and raise the tracks

approximately 50 mm from the ground. See

“OUTRIGGER SETTING” on page 4-43.

2. With the rubber track engaged with the

sprocket, install the crawler on the idler.

3. With the sprocket rotating backward, push

the rubber track in to stop rotation.

Fig. 5-73

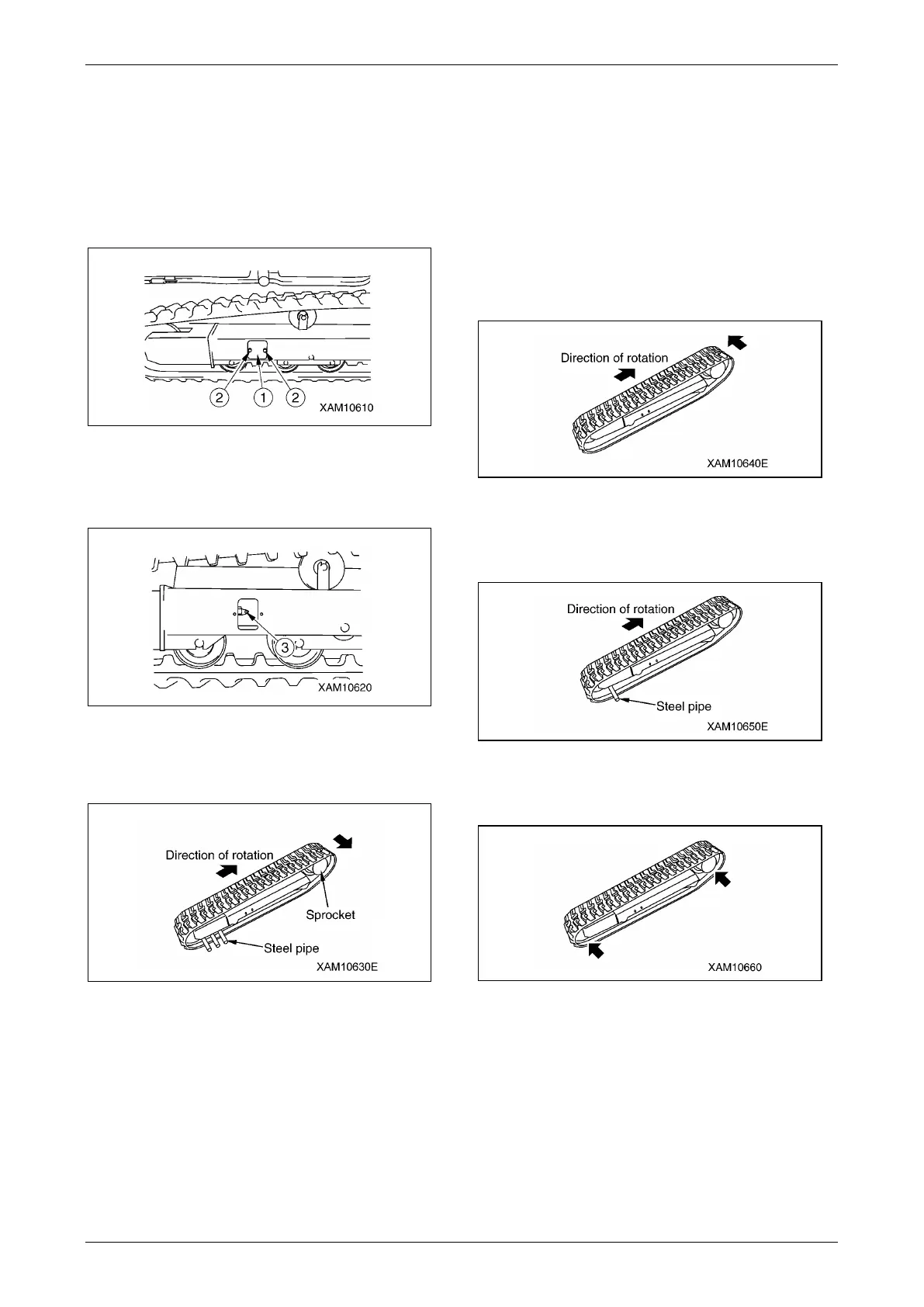

4. Insert the steel pipe between the idler and

rubber track again, and rotate the sprocket to

install the crawler on the idler.

Fig. 5-74

5. Stop rotation and ensure that the rubber track

is on the sprocket and idler properly.

Fig. 5-75

6. Adjust the rubber track tension.

See “Checking Rubber Track Tension” on

page 5-39 and “Adjusting Rubber Track

Tension” on page 5-39.

7. Stow the outriggers and lower the machine to

the ground. See "OUTRIGGER STOWING"

on page 4-53.

Loading...

Loading...