60-44 Maintenance - 600 Service Hours or Twice Yearly VX30/VX50 Gen3/ECO50 Vacuum Systems

MAINTENANCE - 600 SERVICE HOURS OR TWICE YEARLY

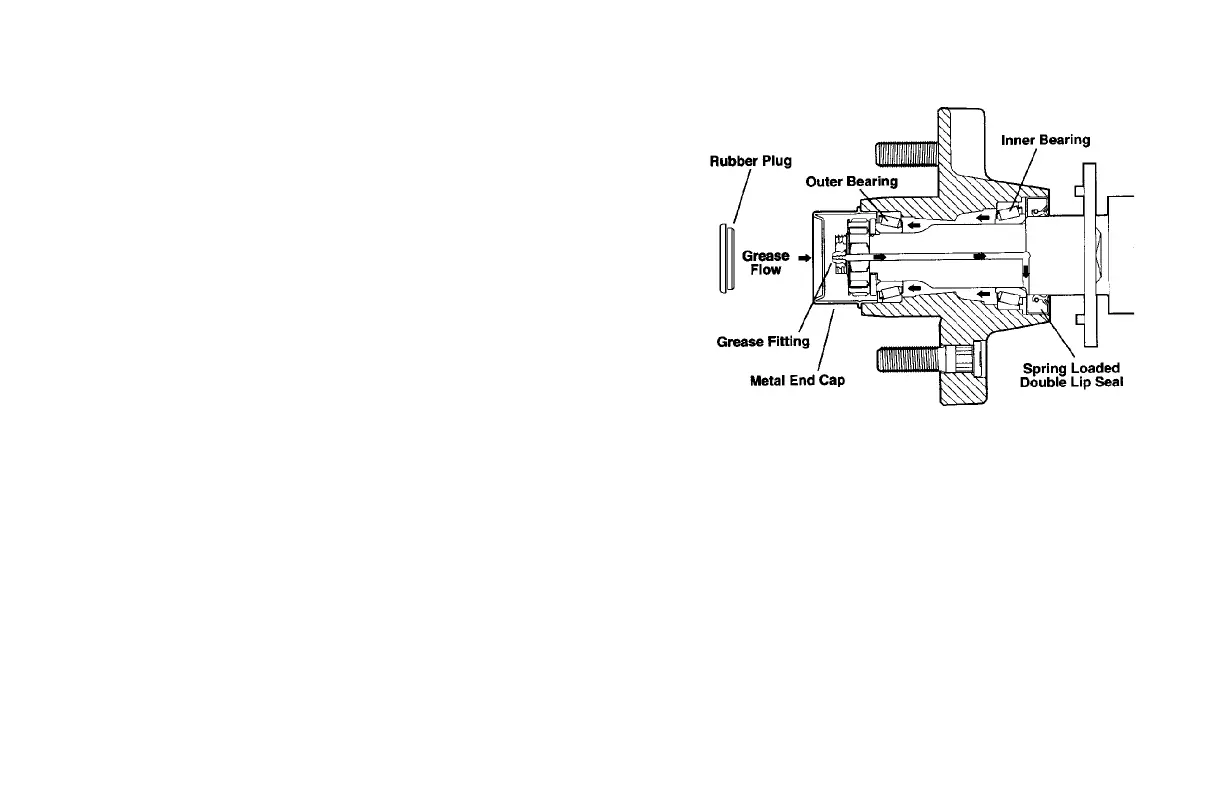

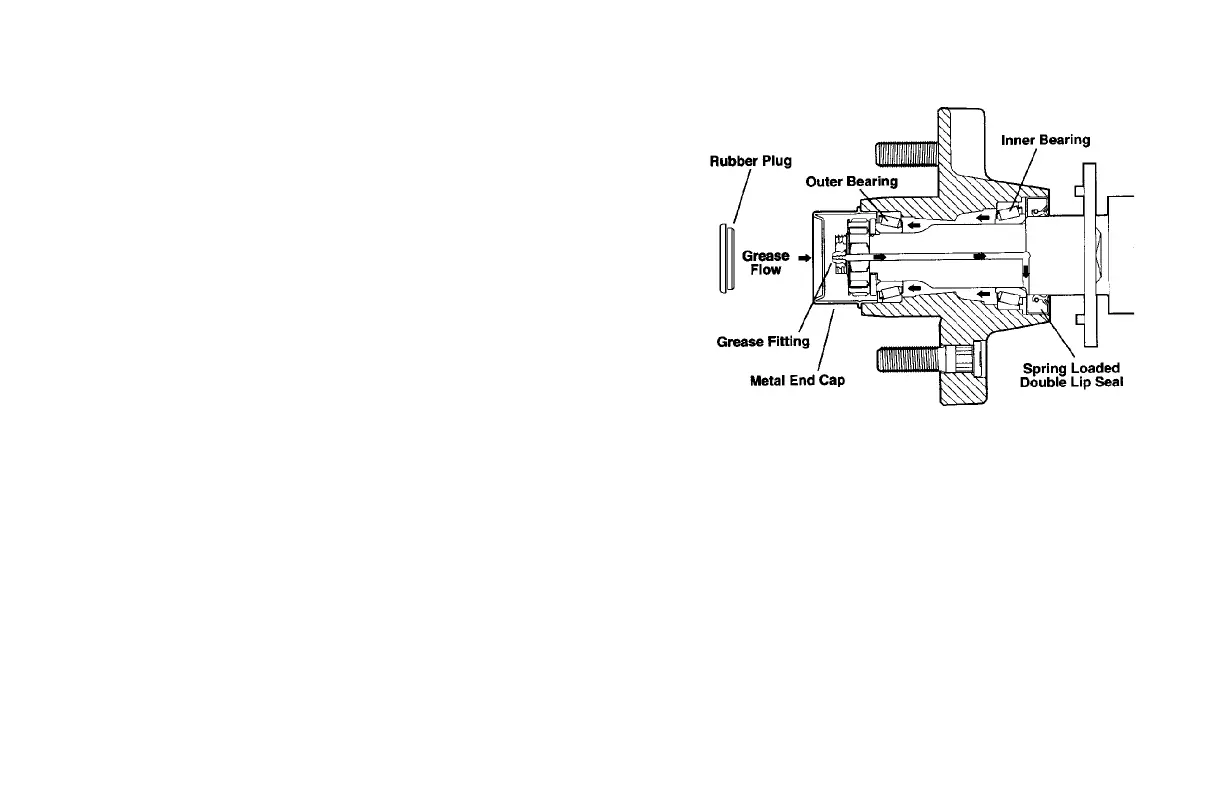

Wheel Bearings - Grease

Step 1: Remove center rubber plug from the end of the grease cap.

Step 2: Place a standard

grease gun onto the grease fitting at the end of

the spindle. Ensure grease gun nozzle fully engages the fitting.

Step 3: Pump greas

e into the fitting. The old displaced grease will begin

to flow back out the cap around the grease gun nozzle.

NOTICE: Rotate

hub or drum while adding grease.

Step 4: When new

clean grease is observed, remove grease gun, wipe off

any excess, and install rubber plug.

Belts - Inspect

Refer to “Belt Maintenance,” page 60-54, for belt maintenance

instructions.

• Inspect and verify the condition of belts; replace as necessary.

• Look for signs of aging such as frayed edges and cracks.

• Tighten belts if necessary.

Loading...

Loading...