OM-278680 Page 4

SECTION 4 − SPECIFICATIONS

4-1. Introduction

The AugmentedArc is an augmented reality (AR) welding training system that provides the new student or the experienced welder the opportunity to

develop, enhance, or verify their welding abilities through an interactive, simulated welding process on a variety of weld joint configurations. This

product is designed to help welding students acquire the necessary welding knowledge, capacities, abilities, welding sensations and skills, thereby

saving the time and money normally spent training in a live welding situation. It is an educational solution to help both students and trainers improve their

learning experience and enhance results and qualifications. The system can be installed as a standalone or classroom configuration.

After the AugmentedArc system is installed, the user turns on the training system, selects the desired welding assignment, puts on the augmented

reality (AR) welding helmet and welding gloves (welding gloves are recommended to simulate a live welding experience), and begins the simulated

welding activity. The cameras and AR markers convey the weld data (gun angles, gun speed, contact tip to work distance [CTWD], aim) to the system

microprocessor, which compares it to the specified weld parameters of the assignment selected. The system evaluates the weld data and grades the

student’s performance.

The AugmentedArc instruction is complementary to training with live welding equipment. To complete their welding training, students should also

practice their acquired skills by welding under the supervision of qualified persons in a safe welding environment.

NOTICE − Do not install or use the Augmented Arc in the same area as live welding equipment.

4-2. System Features And Benefits

S Advanced computer simulation techniques using artificial vision technology create a realistic welding environment.

Teacher software allows the instructor to adapt their training programs to the AugmentedArc system. The instructor can manage and monitor

student activity and progress from a PC (personal computer) (see Section 9).

Analysis mode allows all of the welding exercises performed in the simulator to be visualized, providing detailed results of all of the welding

parameters.

System allows for remote maintenance and software updates, and is adaptable to meet specific training requirements.

The system configuration can be installed as a standalone or classroom application. The standalone application includes a simulator and a

router, and all of the information is saved on the unit. The classroom application can include multiple simulators, a router, and a controller. All

of the information is saved on the controller.

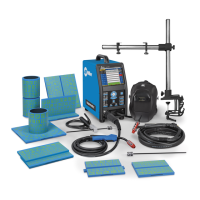

4-3. AugmentedArc Complete Package

Input power and Ethernet cables

are not shown.

1 Simulator

2 Helmet

3 Workpiece Stand

4 TIG (GTAW) Torch And Cable

5 TIG Filler Rod

6 TIG Foot Pedal And Adapter

Cable (Optional)

7 Router

8 MIG (GMAW) / FCAW Gun

And Cable

9 Stick (SMAW) Electrode

Holder And Cable

10 Workpieces (Five Total)

11 WiFi Antenna (Two Total)

12 Controller (Optional, For

Classroom Configuration Only)

161-93 / 161-97 / 161-100 / Ref. 805 465-A

1

2

3

4

7

8

9

10

11

5

12

6

4-4. Serial Number And Rating Label Location

The serial number and rating information for this product is located on the back of the unit. Use rating label to determine input power requirements, and to

register for free software upgrades. For future reference, write serial number in space provided on back cover of this manual.

Loading...

Loading...