OM-278680 Page 23

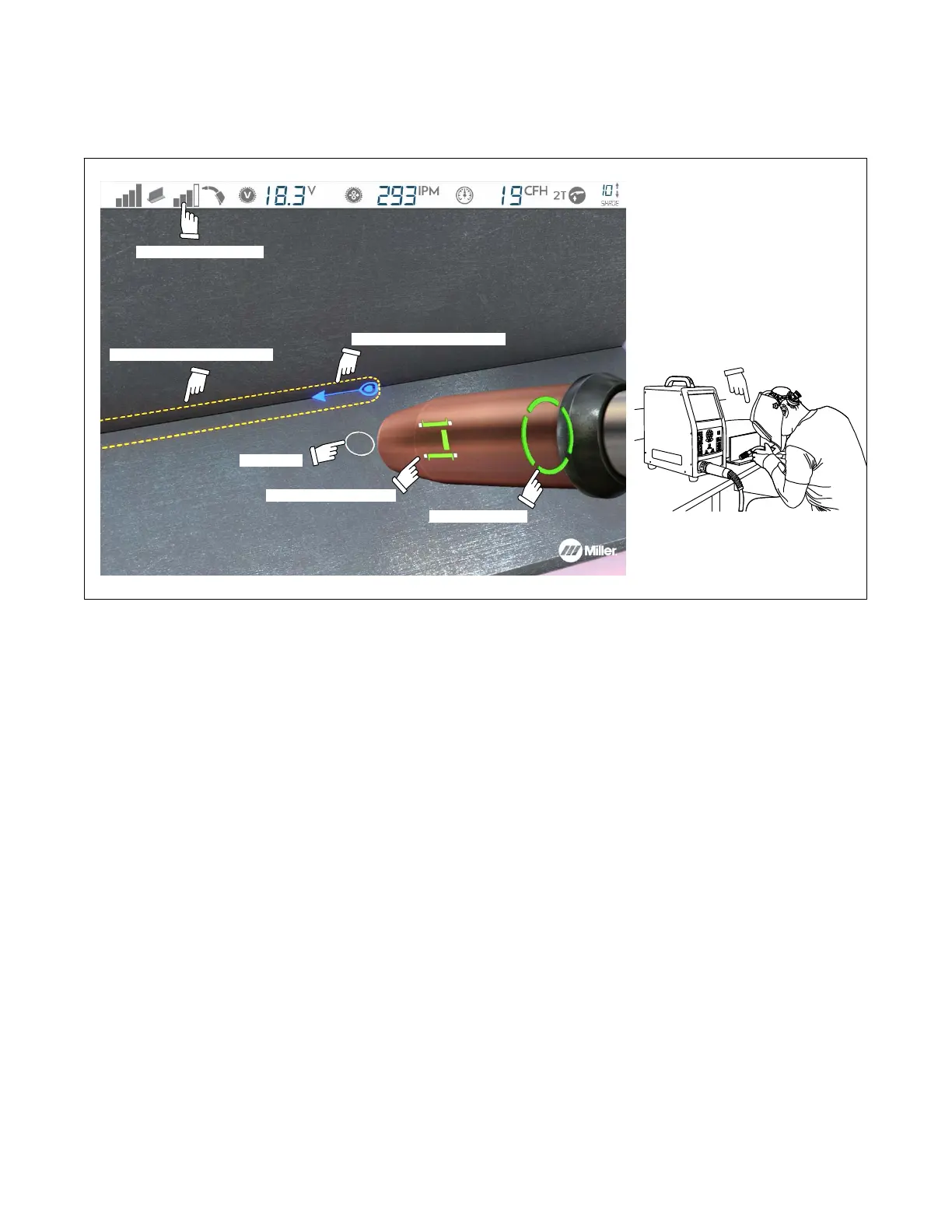

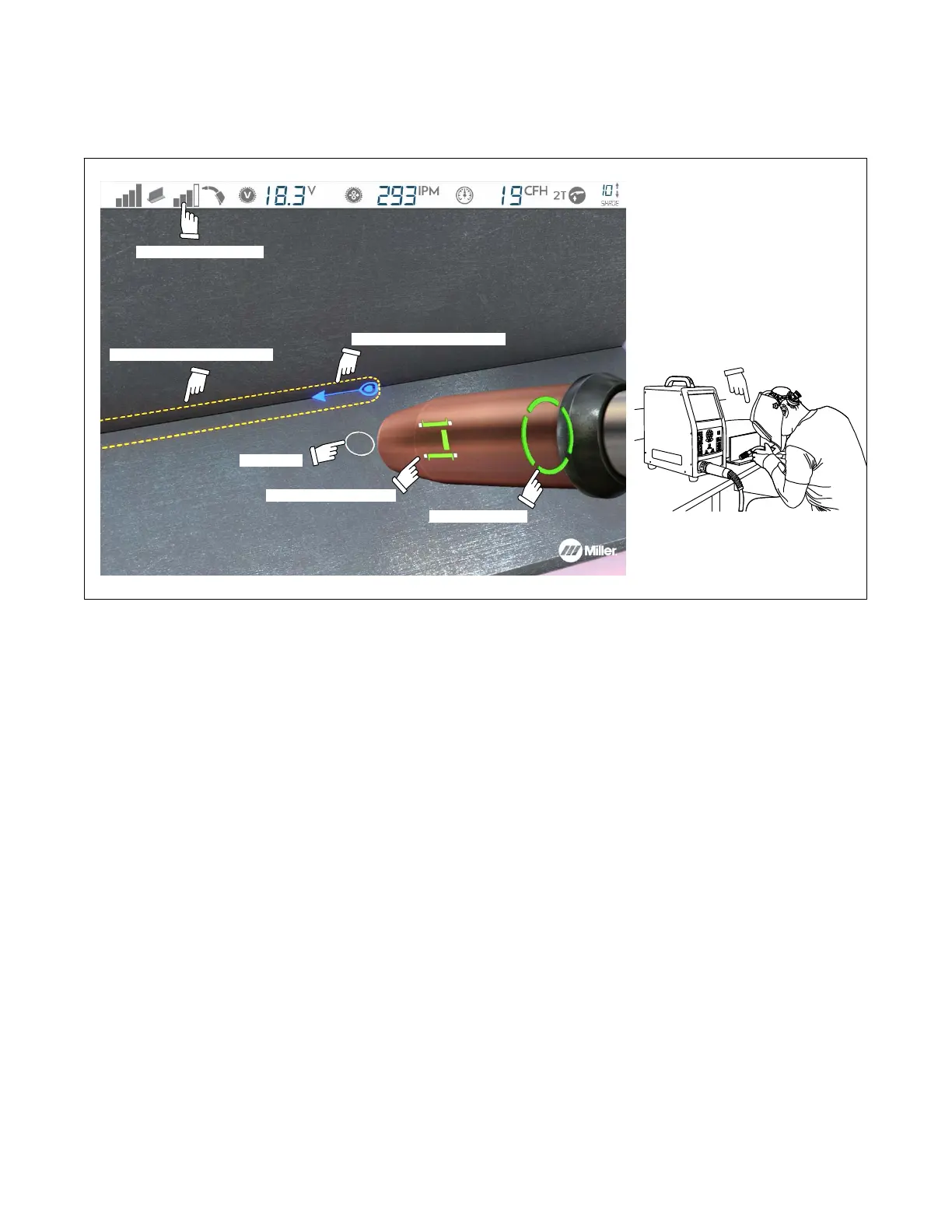

E. Determining Correct Position Of MIG Gun/Electrode And AR Helmet

Place the gun/electrode at the simulated weld joint (visible through the helmet). The screen will display an error message if the system is not

tracking the gun/electrode. Adjust gun/electrode position, helmet lighting, and helmet position to clear the tracking error. Use the simulated guides

to help you adjust the gun/electrode angle, direction, and contact tip to work distance (CTWD) to acceptable limits. The guide(s) will display in red

if the gun/electrode is not in the correct position; guides shown in green indicate the gun position is acceptable (Figure 7-13).

Gun angle guide

Gun tracking indicator

Contact tip-work guide

Simulated weld-joint location

Use onscreen guides

to ensure correct position of

gun/electrode and helmet.

161-098

For best results, position gun so

two faces of AR tip are visible to

cameras in helmet.

Required direction of travel

Aim guide

Figure 7-13. Review Gun/Electrode Positioning Guides Before Welding

Position gun/electrode near weld joint. Pull trigger and move gun along entire length of weld joint in the correct orientation and speed as indicated

on the helmet screen. Pay close attention to on-screen guides while welding (Figure 7-14 thru Figure 7-16) and adjust technique as necessary.

Release trigger and check score (see Section F). For stick welding, when the marker block is seen to be close enough to the sticker markers on

the electrode holder, the weld simulation and electrode retraction will automatically pause. To continue, reset the electrode position within the

electrode holder and resume simulated welding.

During the weld simulation, the screen darkens to simulate the darkening of a real welding helmet. Use the up/down arrow buttons to adjust the

simulated helmet shade from 8 (lightest) to 13 (darkest), as desired.

Loading...

Loading...