281

CHAPTER 7 CONVENIENT USAGE OF DEVICES

7

7.2 Local Device

(3) Local devices when executing a subroutine program

When executing a subroutine program, the local device in the file where the subroutine program is stored can be

used by ON/OFF of SM776.

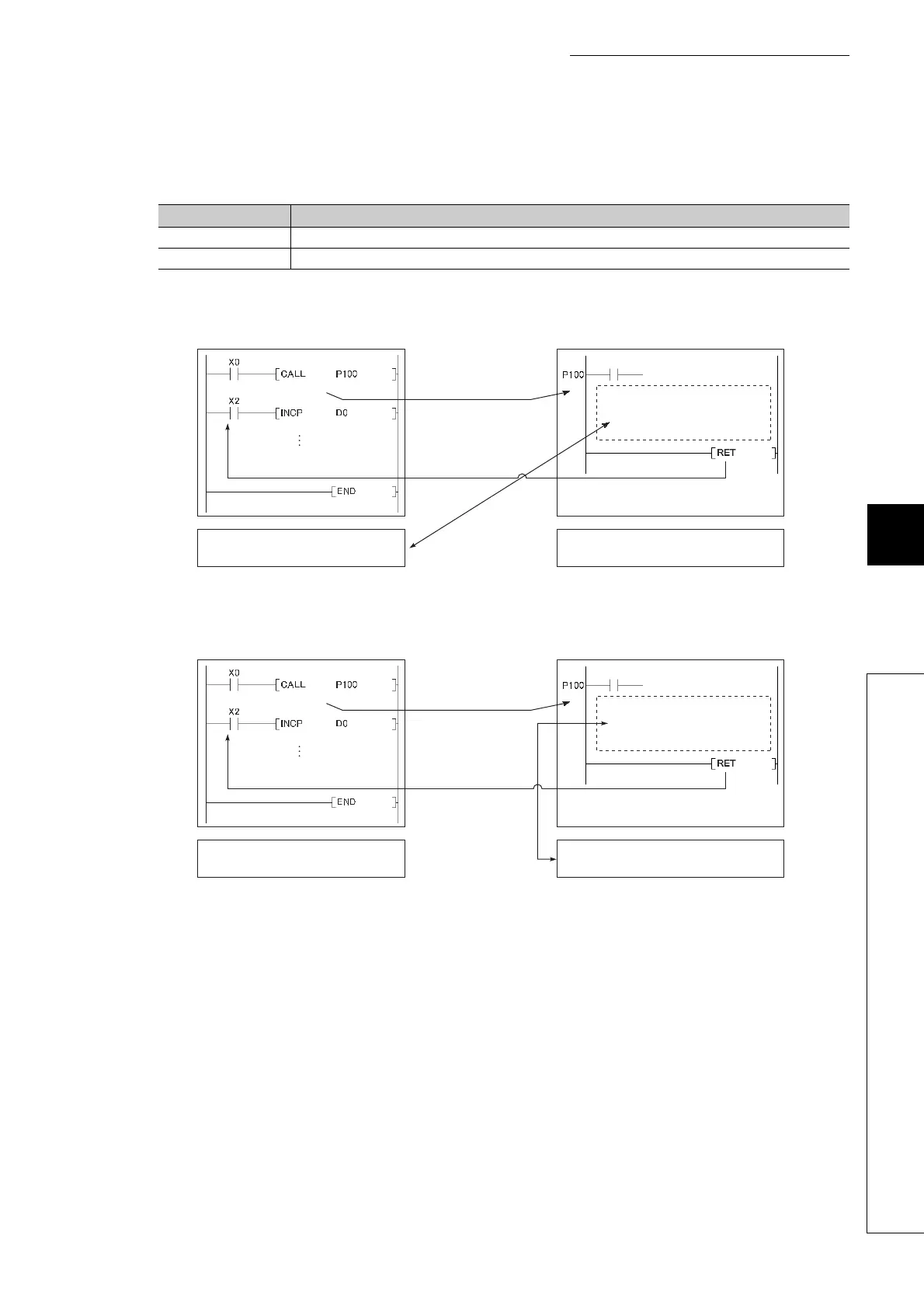

(a) When SM776 is off

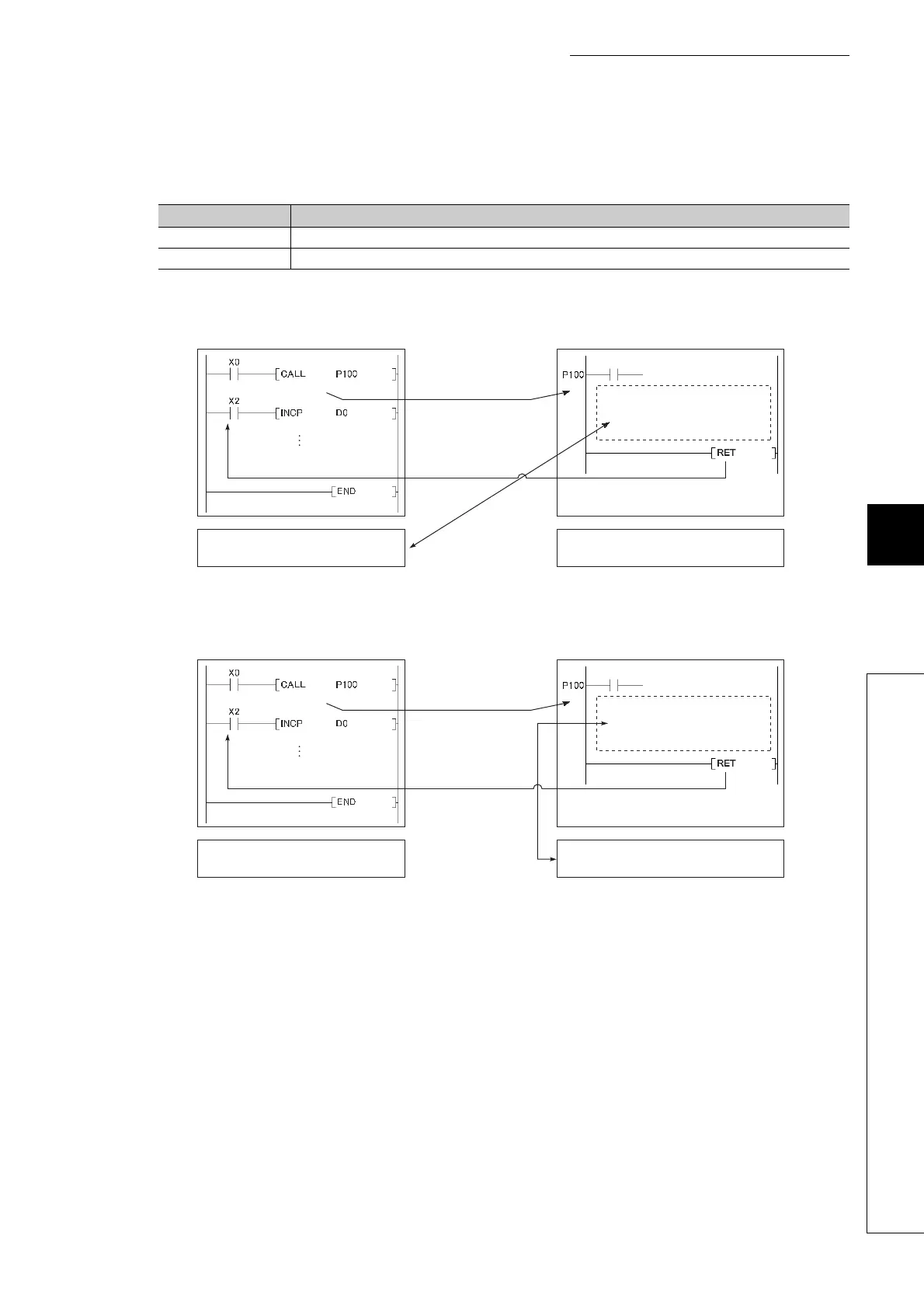

(b) When SM776 is on

(c) Precautions

• When SM776 is on, local device data area read out when a subroutine program is called, and the data are

saved after execution of the RET instruction. Because of this, the scan time is increased if one subroutine

program is executed with SM776 set to on.

• The on/off status of SM776 is set for each CPU module. It cannot be set for each file.

• If the on/off status of SM776 is changed during program execution, control is implemented according to

the information after the change.

SM776 Operation

OFF Perform operations with the local device that corresponds to the source file of the subroutine program.

ON Perform operations with the local device that corresponds to the file where the subroutine program is stored.

Local device area

for file name, ABC

Local device area

for file name, DEF

Execution of subroutine

program

Local device

writing/reading

File name: DEF

(Standby type program)

File name: ABC

Subroutine program

Local device area

for file name, ABC

Local device area

for file name, DEF

Execution of subroutine

program

Local device

writing/reading

File name: DEF

(Standby type program)

File name: ABC

Subroutine program

Loading...

Loading...