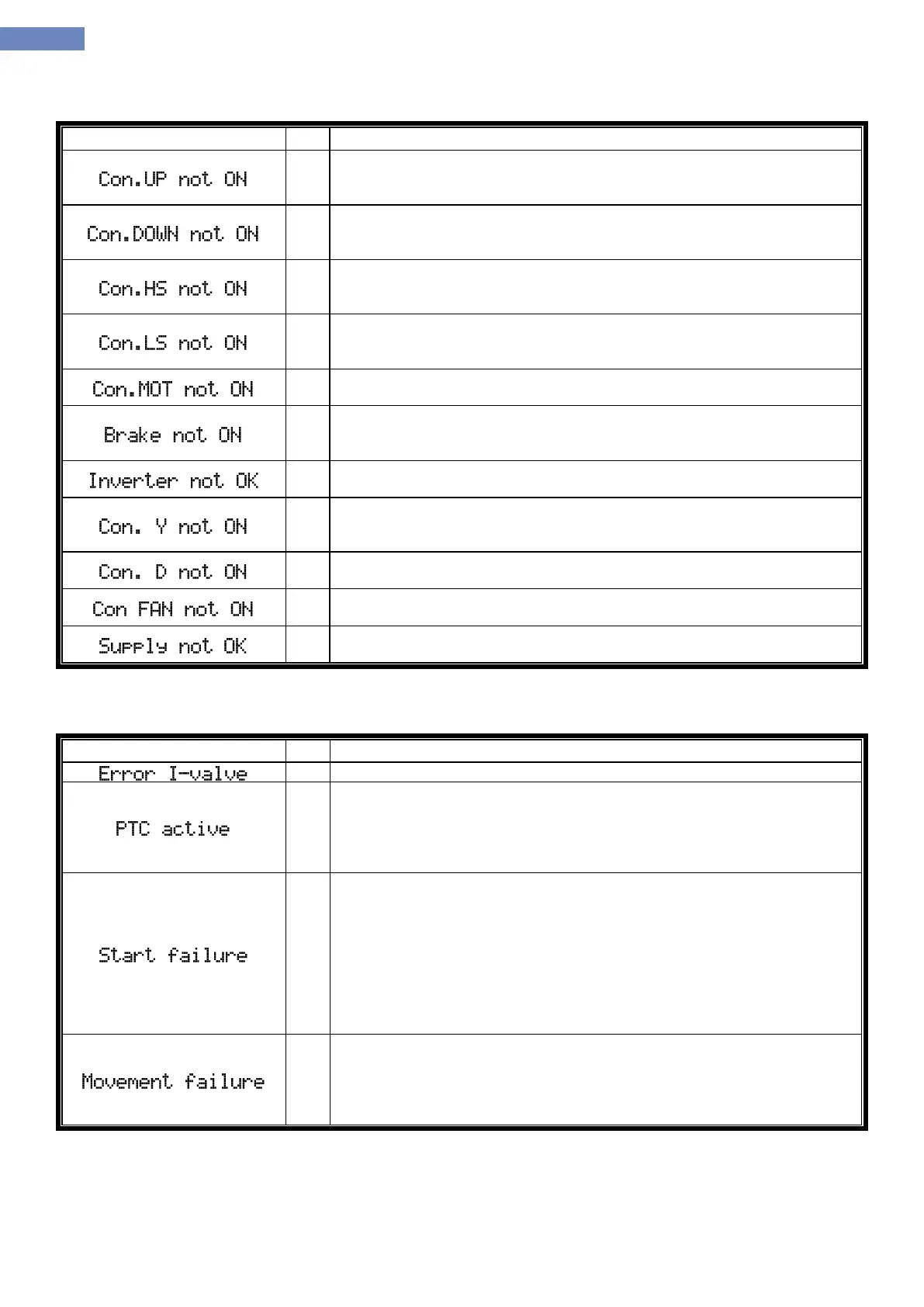

Messages that describe the contactor activation failure in the control group:

Indicates a direction up contactor activation fault. Contactor is controled by

defined input FI-220. Contactor must be on 2 seconds after system turns on

the output function FO-001.

Indicates a direction down contactor activation fault. Contactor is controled

by defined input FI-221. Contactor must be on 2 seconds after system turns

on the output function FO-002.

Indicates a high speed contactor activation fault. Contactor is controled by

defined input FI-223. Contactor must be on 2 seconds after system turns on

the output function FO-004.

Indicates a low speed contactor activation fault. Contactor is controled by

defined input FI-222. Contactor must be on 2 seconds after system turns on

the output function FO-003.

Indicates motor contactors activation fault, used with frequency regulated

elevators . Contactors are controled by defined input FI-225.

Indicates a failure to activate electromechanical elevator brake. Brake

control is done over brake contact at the input FI-224. Signal must be present

while traveling, and max 2 seconds after direction contactors activation.

Indicates a frequency regulator fault. Controled by input FI-226. Regularity

signal must be present all time.

Indicates a „star“ contactor activation fault used with hydraulic elevators.

Contactor is controled by defined input FI-227. Contactor must be on 2

seconds after sytem turns on the output function FO-013.

Indicates a „delta“ contactor activation fault used with hydraulic elevators.

Contactor is controled by defined input FI-228

Indicates a motor fan contactor fault. Contactor is controled by defined input

FI-209. Contactor must be on after system turns on output function FO-018.

Indicates a phase presence and sequence control relay fault. Relay is

controled by input FI-204.

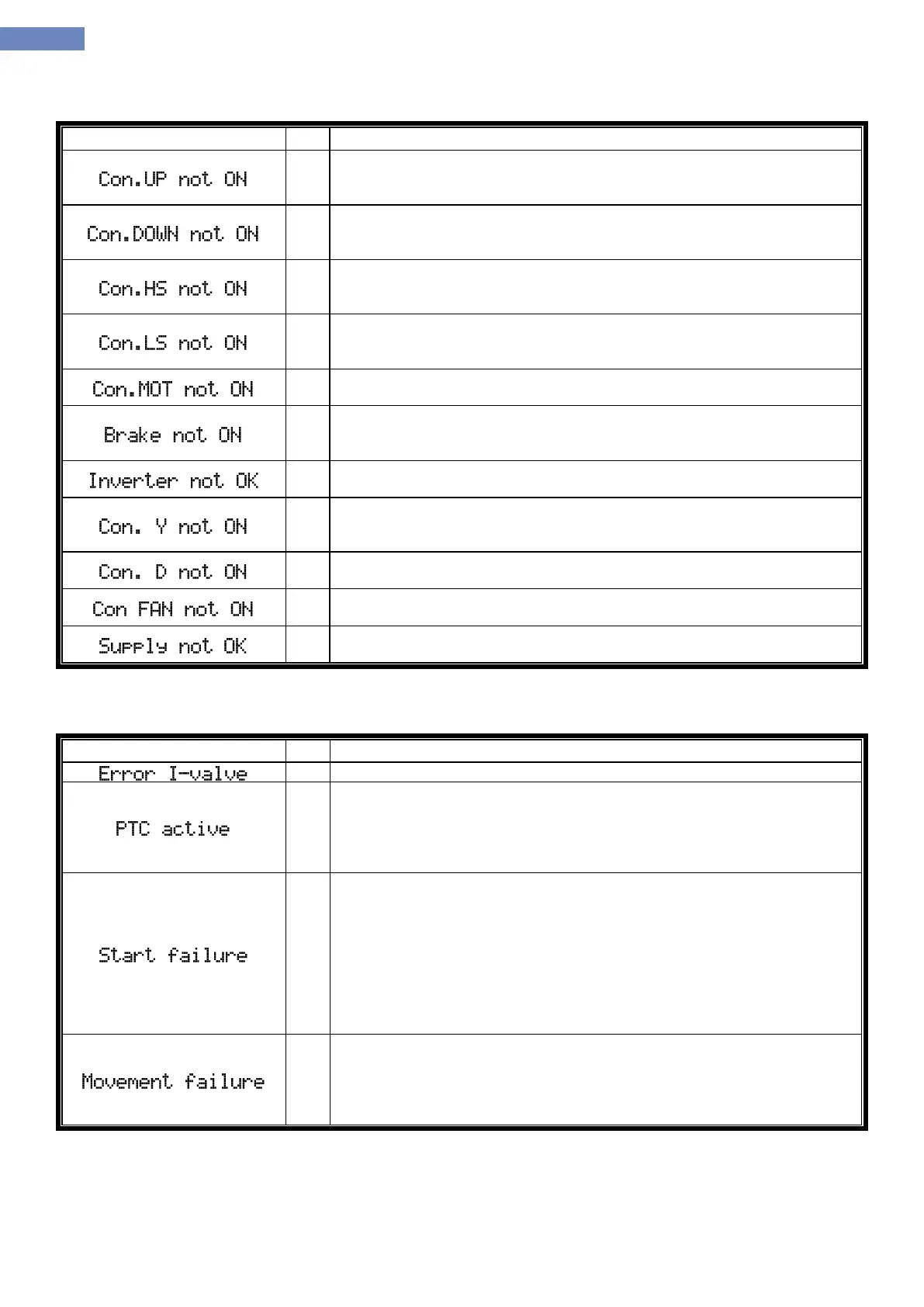

Table with warnings and other failures:

Indicates that Bucher I-Valve don’t give output and it’s in error FI-313.

Indicates that the resistance of PTC sensor is above limit set by parameter

I-02 (hot state PTC resistance). Error remains on for another five min after

the signal, or once the probe resistnace falls below the value set by

parameter I-01 (cold state PTC resistance). Current PTC resistance can be

monitored in the menu inputs/outputs.

Indicates that the elevator after establishment of control signals from the

control group was not initiated in time set by parameter I-03. As a start

control, group takes into account all the signals except for a pulses for

copying used in copiying type 4 or 5 E-01. Parameter should be set to a

sufficient value needed to elevator pass the path between the 2 copiyng

signals when traveling at low speed increased by approximately 20%. After

activating the error it is necessary to reset the control disconnecting power

supply or using the reset button on LC100-D terminal. Inspection travel is

possible.

Indicates that the elevator after start from the station has not moved for

logner that the time set by parameter I-03. This message is identical to the

protection Start failure with the difference that after the start at least one

copying signal has changed . It is necessary to reset the control

disconnecting power supply or using the reset button on LC100-D terminal.

Loading...

Loading...