Maintenance

6-10 October 2019 16K PLUS

Air Brake Maintenance - Continued

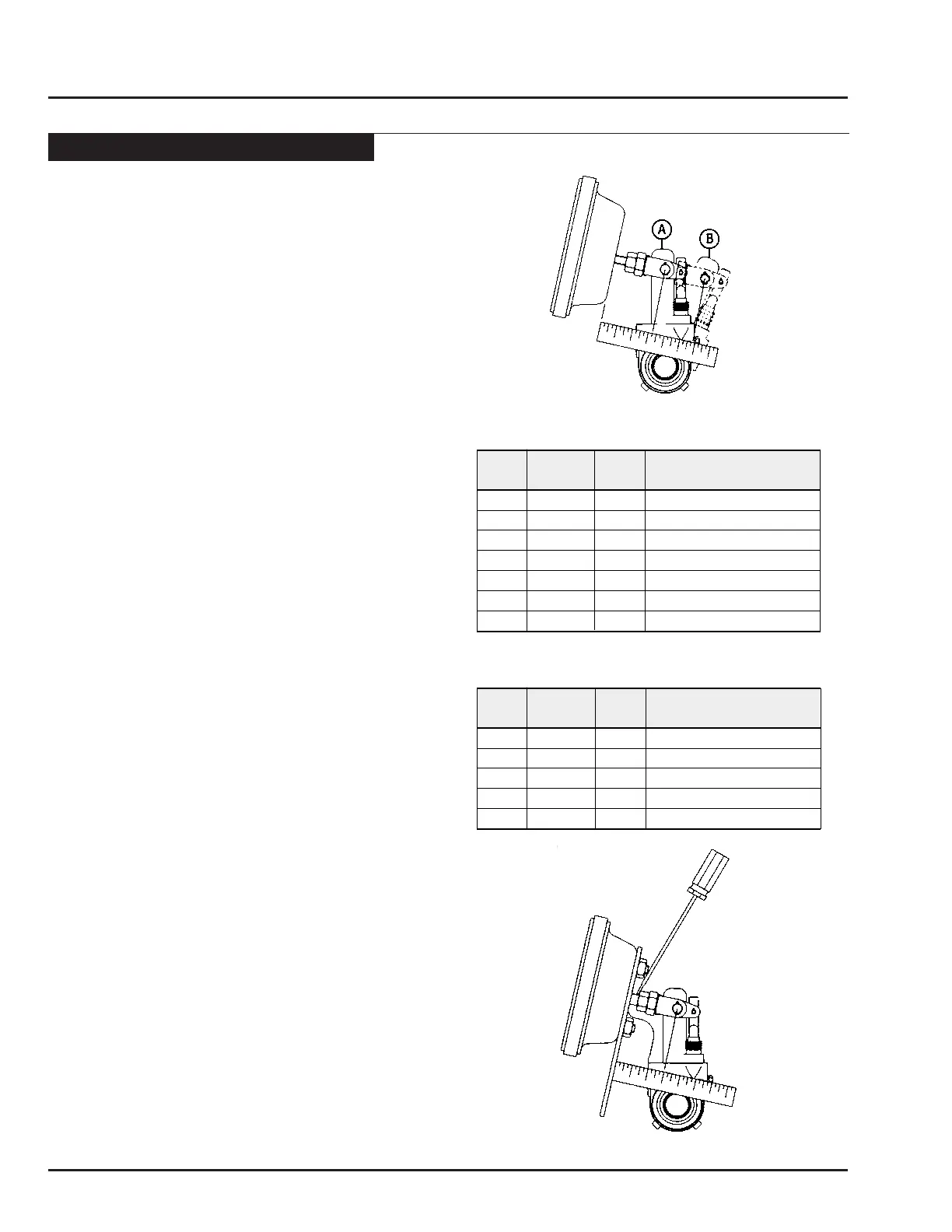

Adjust the brakes as follows:

1. Rotate the hex extension clockwise until the brake

linings contact the brake drum. Back off the slack

adjuster by rotating the hex counterclockwise 1/2

turn.

2. Backing off the slack will require approximately 25

to 30 ft lbs of torque. When backing off the slack

adjuster, a ratcheting sound will be heard.

3. Using a ruler, measure the distance from the face

of the air chamber to the center of the large pin

in the clevis (A) (see g. 3). Make an 85 psi brake

application and allow the chamber push rod to travel

its maximum stroke. Measure to the center of the

large pin (B). The difference between (A) and (B)

is the push rod stroke. Check the following chart

for proper maximum stroke after adjustment of the

brakes.

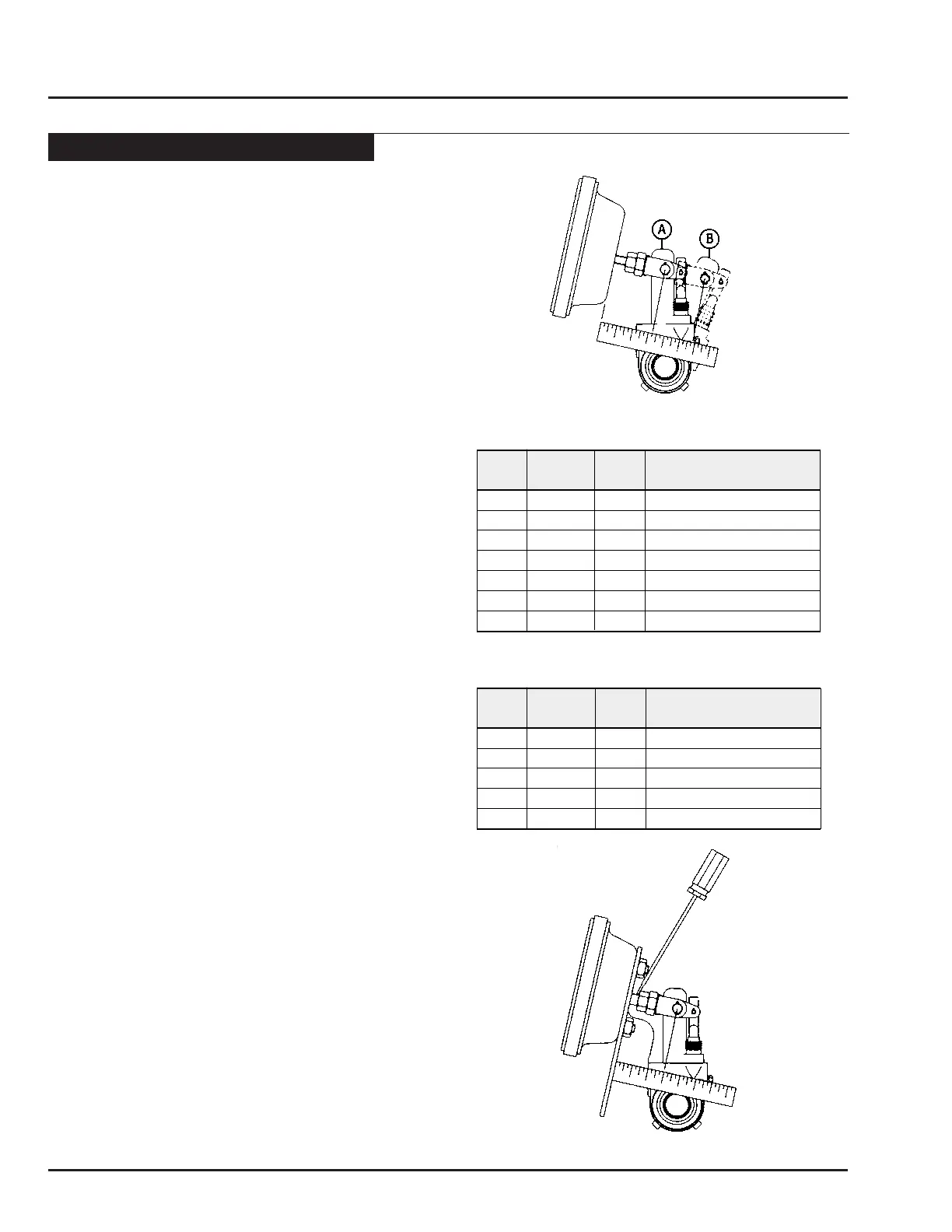

Measuring the Free Stroke

4. Free stroke is the amount of movement of the slack

adjuster required to move the brake shoes against

the drum. With brakes released, measure from the

face of the chamber to the center of the clevis pin.

Use a ruler to measure the movement of the slack

adjuster until the brake shoes contact the drum (g.

4). The difference between the released and applied

measurements is the free stroke. The free stroke

should be 3/8” to 5/8”. If the free stroke is good, but

the applied stroke is too long, there is a problem with

the foundation brake. Check the foundation brake for

missing or worn components, cracked brake drums,

or improper lining to drum contact. If the free stroke

is greater than the recommended distance (3/8” to

5/8”), a function test of the slack adjuster should be

performed (see page 6-11). If the free stroke is less

than 3/8”, a dragging brake can occur. Check to see

that the manual adjustment procedure was followed

correctly. Manually readjust the brake following the

procedure on this page.

Figure 3 - Measuring Maximum Stroke

Outside

Rated Maximum stroke at which

Type Diameter

Stroke brakes must be readjusted

9 5-1/ 4 1.7 5 1-3/8

12 5-1 1/1 6 1.7 5 1-3/8

16 6-3/8 2.2 5 1-3/ 4

20 6-2 5/3 2 2.2 5 1-3/ 4

24 7- 7/ 32 2.2 5 1-3/ 4

30 8-3/3 2 2.5 0 2

36 *93.00 2-1/ 4

Outside

Rated Maximum stroke at which

Type Diameter

Stroke brakes must be readjusted

16 6-3/8 2.5 0 2

20 6-2 5/3 2 2.5 0 2

24 7-7/ 32 2.5 0 2

24 *7-7/3 2 3.00 2-1/2

30 * 8-3/3 2 3.00 2-1/2

*Note: If type 36 chamber is used, slack length should be less than 6”.

*Note: Identified by square air port bosses.

“LONG STROKE” CLAMP TYPE BRAKE CHAMBER DATA

“STANDARD” CLAMP TYPE BRAKE CHAMBER DATA

Loading...

Loading...