Troubleshooting

16K PLUS October 2019 8-7

Shaft Sensor Shaft Sensor

The Shaft sensor is used to monitor the location of

the power slide as it moves up and down the bed. To

view what the computer is reading for the power slide

position, go to the “Measure - Sensors” menu. The

units of measurement are “pulses”. Each time a tooth

of the star wheel passes by the sensor, it either adds

or subtracts a “pulse” depending on the direction the

tooth is going.

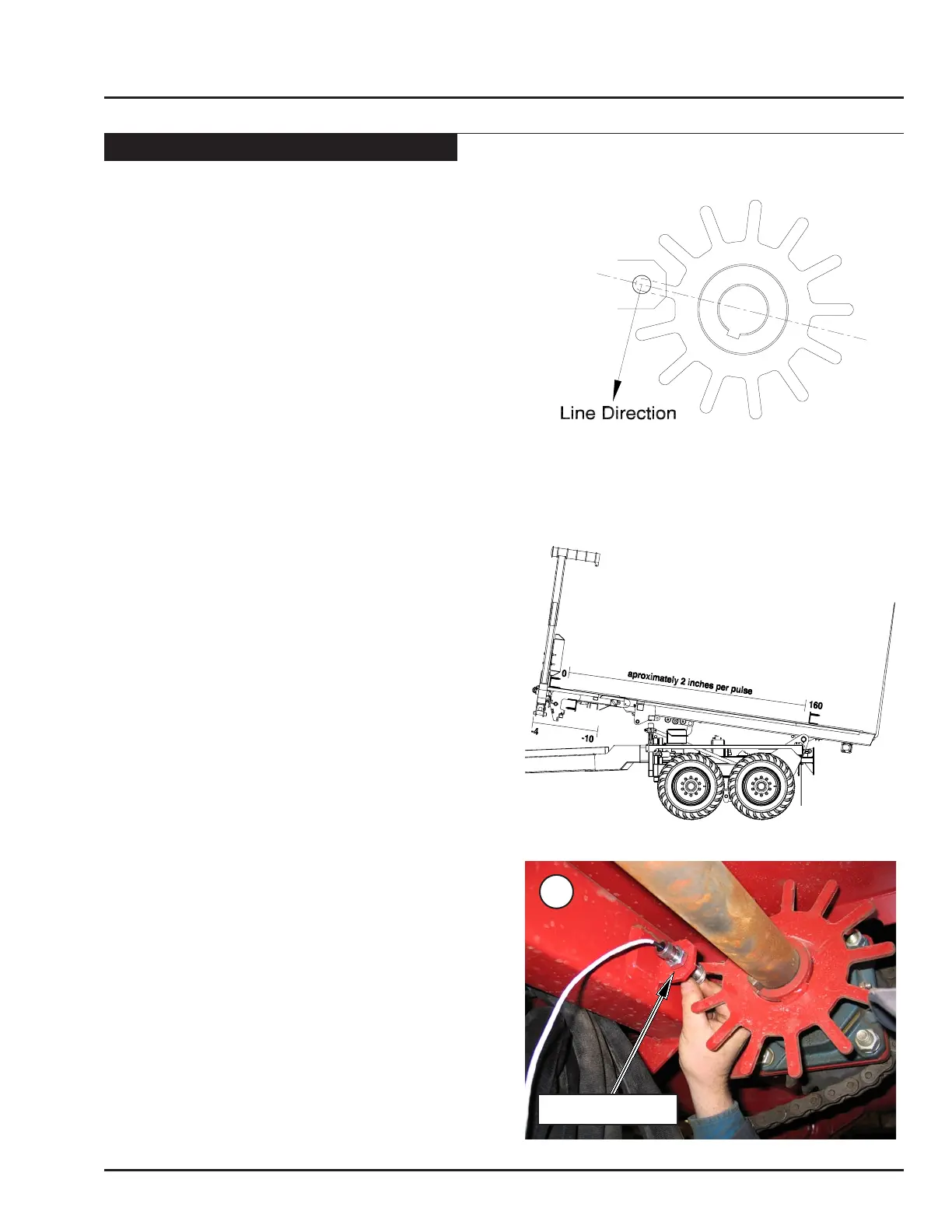

It is very important that the shaft sensor is oriented

correctly so it reads in the correct direction. See the

following diagram to determine the correct sensor

position.

Common causes for the Shaft sensor to not function

properly include:

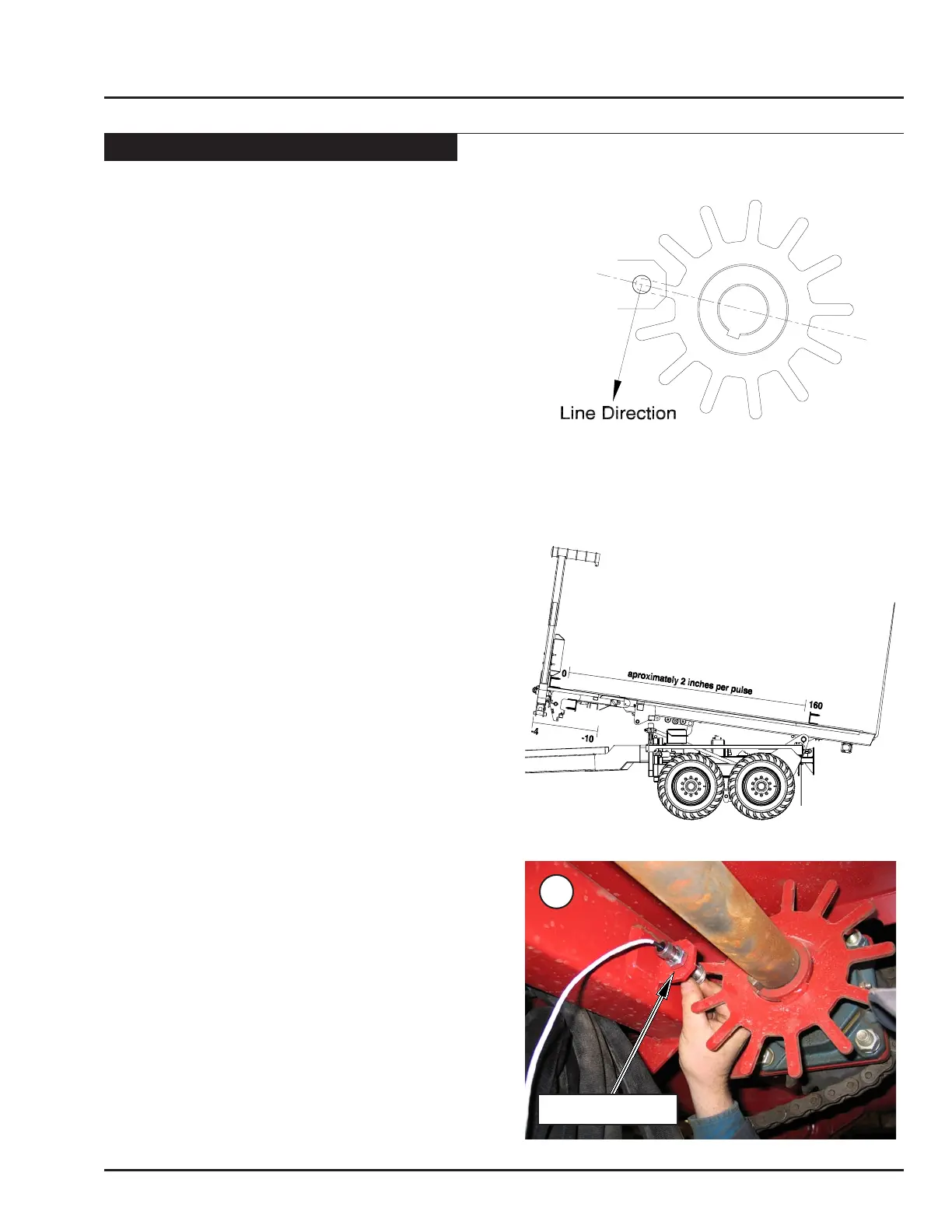

• Incorrect orientation: If the sensor is not oriented

correctly, it will not function properly. The number of

“Pulses” should increase as the power slide move

to the back of the machine, and should decrease as

the power slide returns toward the home position.

Typically, the power slide “Pulses” should be as

shown

• Incorrect sensor gap: The gap between the sensor

and the star wheel should be 1/16 of an inch. Too

large a gap may give inconsistent readings.

Important: Insufcient gap may allow the sensor to

contact moving parts and be destroyed.

• Debris on sensor: Small metallic particles can build

up on the sensor causing it stop working. If metal

lings are building up on the sensor, determine the

cause of the lings and rectify the problem. If the

machine is being operated in an area with volcanic

ash, such as the Pacic North West, it may be

necessary to regularly clean the sensors of debris.

• Sensor failure: From time to time sensors will fail. If

you suspect this, rst test the wire harness for shorts

or broken wires. Otherwise, use a known working

sensor to test the operation of computer and harness.

See “Harness Schematics” for more information.

16k PLUS Control System - Continued

Sensor Troubleshooting - Continued

SHAFT SENSOR

8

Note: Failure to orient the Shaft sensor correctly

will result in erratic or incorrect readings.

Loading...

Loading...