Operation

16K PLUS October 2019 5-13

Power Slider Chain Tension

Setting Alignment Arm Pressure

• When the stacker picks up a bale in automatic mode, the arms will squeeze until the hydraulic pressure in the

cylinder exceeds the set-point. The arms then stop squeezing, and the loader starts raising. There are two

pressure set-points for the stacker. The 1st Bale Pressure is used for the rst bale picked up, and the 2nd Bale

Pressure is used for the next one. In the case of 3 X 3 bales, the 2nd Bale Pressure is also used for the third bale.

If the alignment arms don’t appear to be squeezing the bales tight enough or the bales are slipping through the

alignment arms, the pressure probably needs to be increased. If the alignment arms appear to be squeezing the

bales too tight and the bales are bowing in the middle, the pressure probably needs to be decreased.

• The Alignment Arm Pressure can be adjusted from the Adjust menu. See Adjust Menu: Example: Changing

the Squeeze Pressures for details.

Chain Tension Adjustments

Warning: When making adjustments on the Bale

Runner, always stop the towing vehicle, set the parking

break, disengage the PTO and all power drives, shut off

the engine and remove the ignition keys.

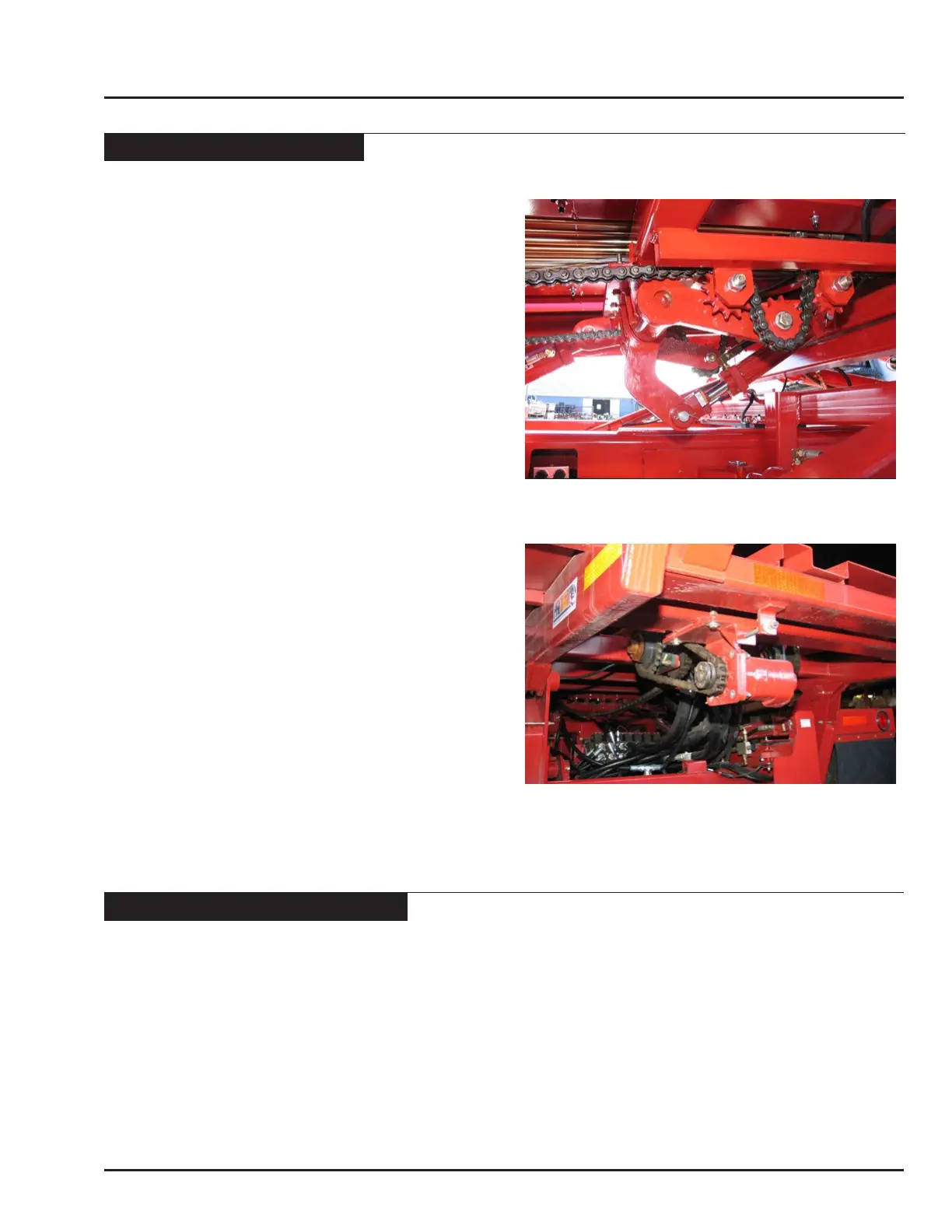

• If the power slider chains are jumping teeth or appear

to be over tightened, then the power slider chain

tension may need to be adjusted.

• The Power Slider Chain Tension is controlled by a

hydraulic pressure reducing and relief valve located

on the side of the pushoff. The aluminum valve has

an adjustment screw protruding from the rear of

the valve. Once the 9/16” jam nut is loosened, the

adjustment screw can be turned with a 5/32” Allen

wrench. When adjusting the system use small

increments (1/4 turn), bottoming out the adjustment

nipple or over pressurizing the system could

potentially damage hydraulic components. Turning

the adjustment screw in (clockwise) increases

pressure, and turning the screw out (counter

clockwise) decreases the pressure.

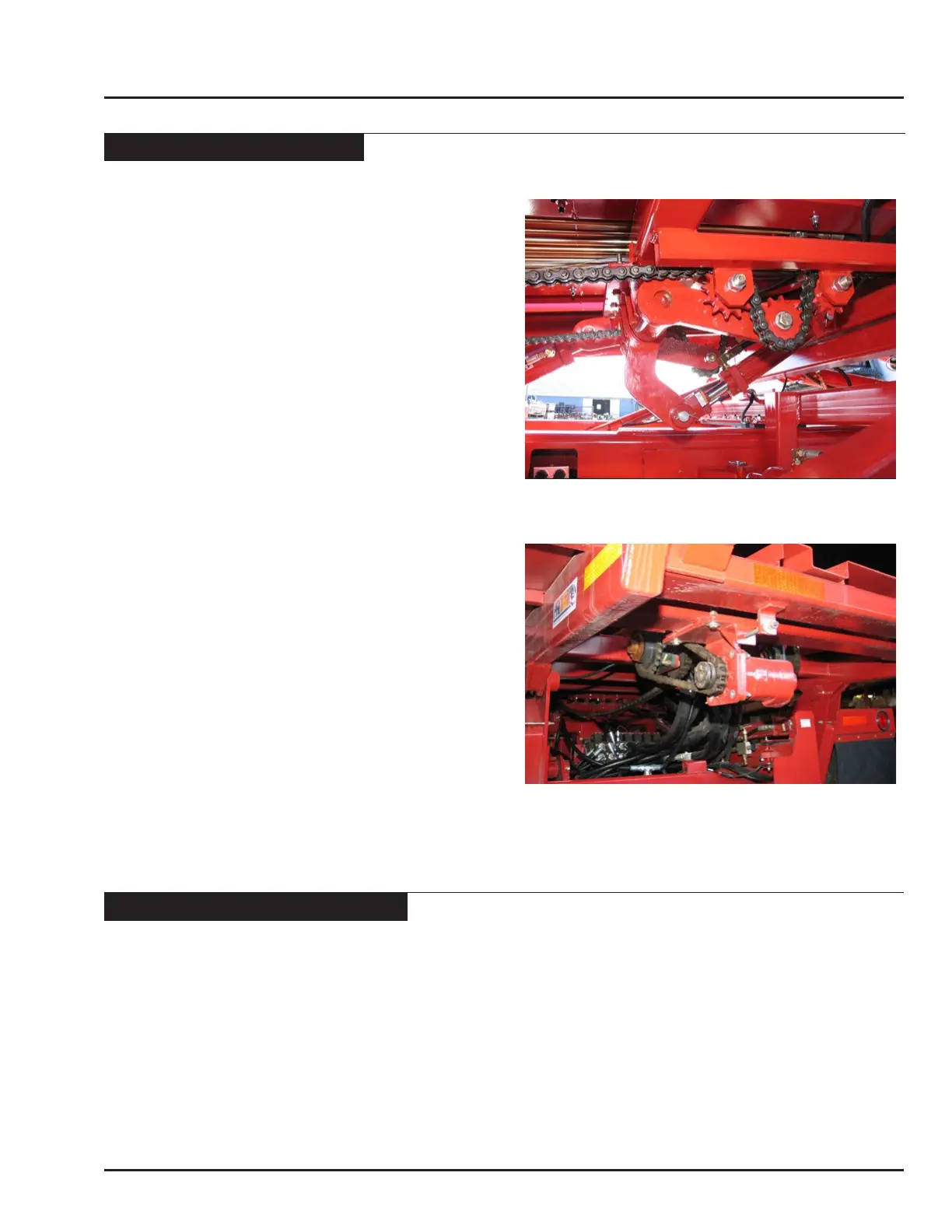

• Adjusting the Motor Chain Tension can be

accomplished with two 3/4” wrenches. First

loosen the four (4) bolts holding the motor mount

to the bed. Then adjust the threaded rod until the

appropriate amount of tension is achieved in the

chain. (Approximately 3/4”of slack in the middle of

the slack side of the chain.) Re-tighten all bolts and

torque to specs. (Page 6-20)

Motor Chain Tension

Loading...

Loading...