Maintenance

6-8 October 2019 16K PLUS

General Maintenance

General Check

• Lug nuts should be tightened to 450-500 ft-lbs.

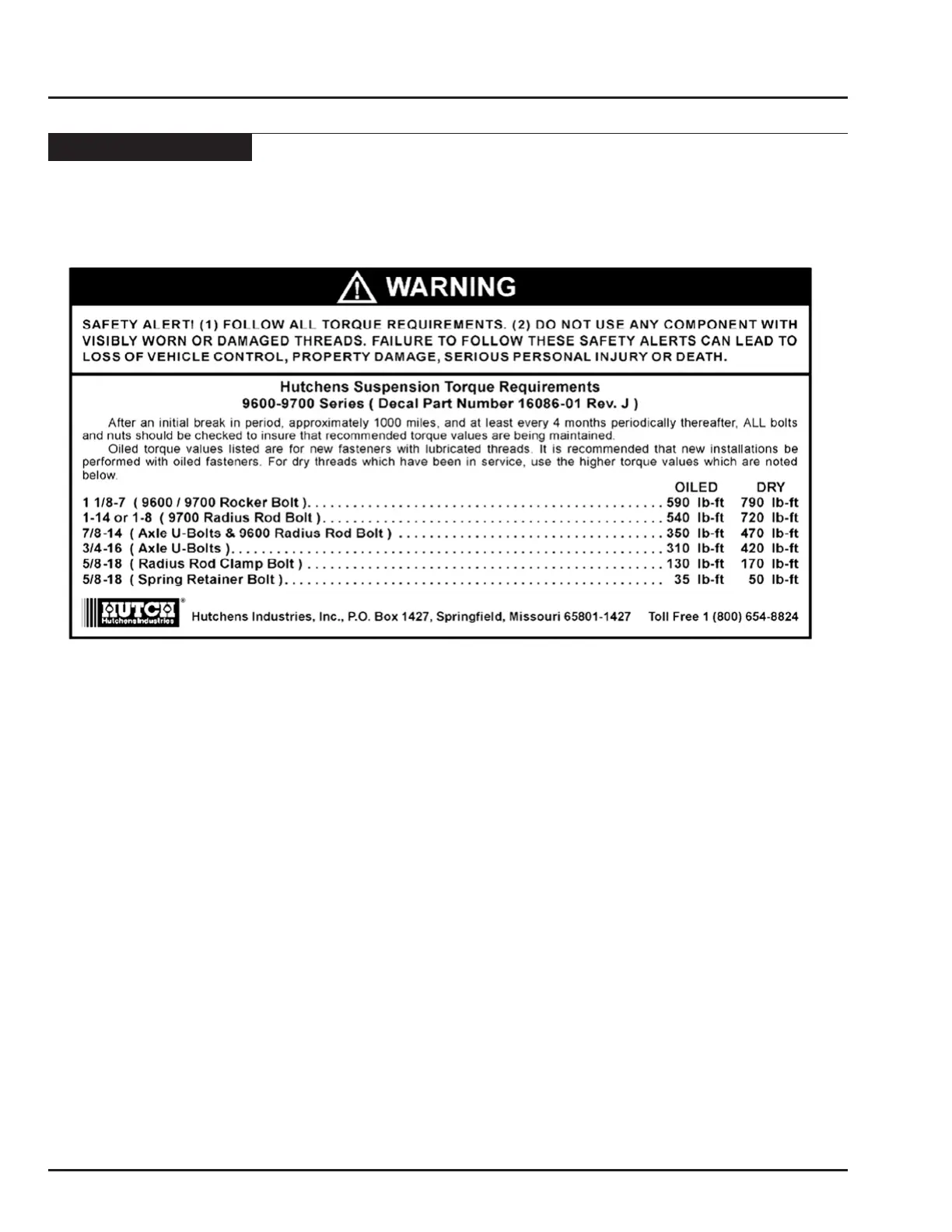

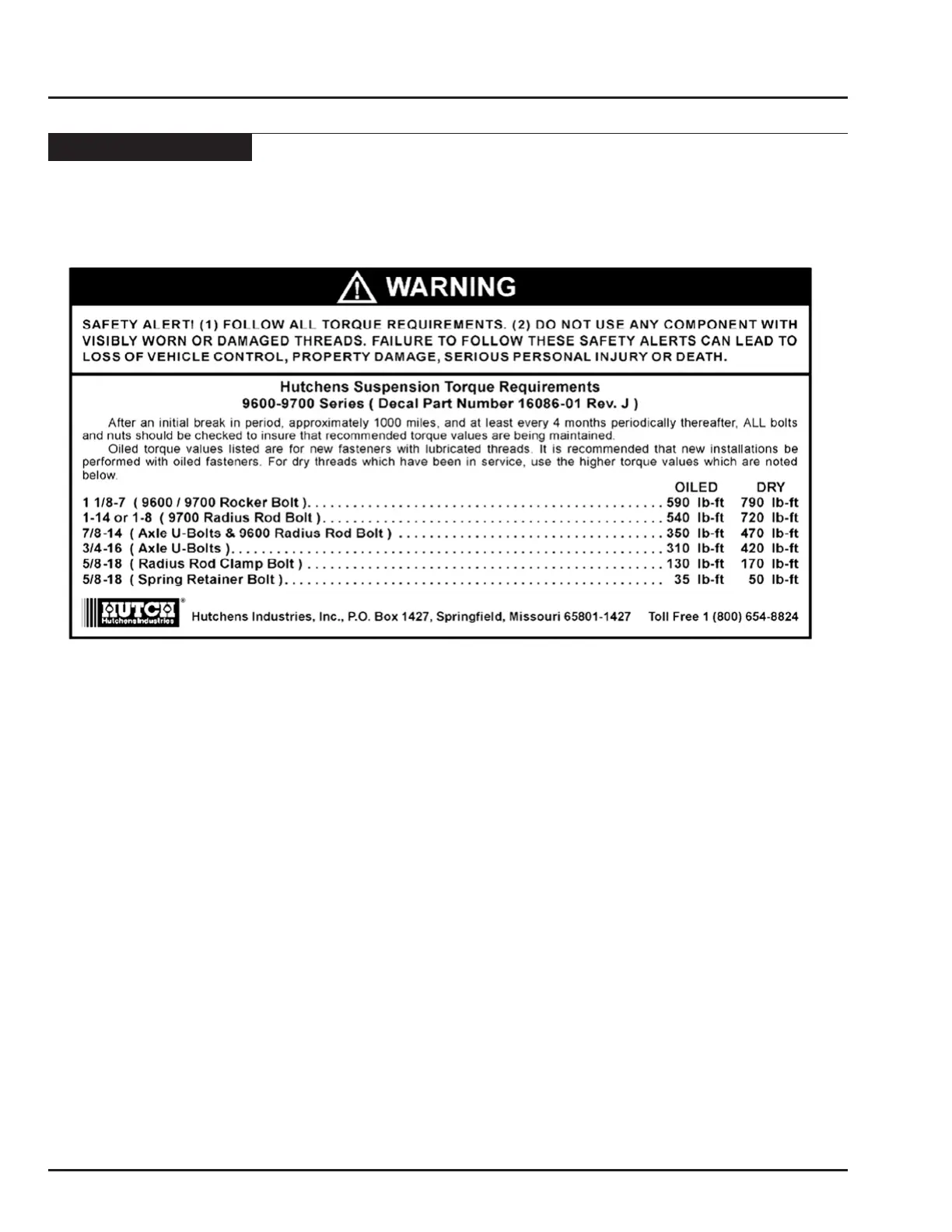

• Bolts in axle suspension system should be tightened to the values on decal 10774 shown below.

• Alignment Arm Chains should be kept tight to prevent cracking of the Loader. Check the chain tightness by visually

inspecting the chains when the Loader is fully raised. The chains should have little or no slack.

To tighten Alignment Arm Chains

1. Jack up the ends of the Alignment Arms and block them in place. This should create the most slack in the chain.

2. Release the safety latch and unhook the grab hook. Determine the link that would eliminate the most slack in

the chain.

3. Remove the double clevis pin in the end of the chain, hook the grab hook on the desired link, and re-lock the

safety latch.

4. Re-install the pin on the double clevis on the end of the chain through the pad eye on the Alignment Arm.

• Check all plastic wear surfaces used in the machine. These parts are located at the Hitch pivot point, between

the Hitch and the Frame, at the Alignment Arm pivots, and in the Grab Hook pivots.

• Periodically check all bolts. Use grade eight bolts for replacements. A torque chart is provided on page 6-21.

Cylinder Repair

The diagnosis and repair of the hydraulic cylinders on the Auto Align Bale Runner should only be attempted by a

qualied service technician familiar with this type of repair.

Bed Extensions

The bed extensions are used to hold the fth tier in a load, depending on the dimensions of the bales being stacked.

Refer to the chart on page 5-17 to determine if your application requires the use of bed extensions. The bed extensions

can easily be removed, and re-pinned to the loader if it is desired to stack a different sized bale.

Loading...

Loading...