Maintenance

16K PLUS October 2019 6-9

Air Brake Maintenance

Every Three Months or 25,000 Miles

1. Check the condition of the foundation brakes,

including drums, shoes and linings, cams, rollers,

bushings, etc.

2. Check for structural damage of the housing, worn

clevis, worn clevis bushings and condition of the boot

for cuts or tears. Replace if necessary.

3. After allowing the brake drum to cool to room

temperature, check for correct chamber stroke

following the procedure on page 6-10. Due to different

operating conditions, chamber stroke tests may be

necessary at earlier intervals. See charts on page

6-10 for the recommended stroke measurements.

Note: An automatic slack adjuster should not have

to be manually adjusted except for initial

installation and at the time of brake reline.

Every Six Months or 50,000 Miles

Gunite slack adjusters are factory lubricated and

extensively sealed to protect against dirt, water, salt

and other corrosive elements. Nevertheless, periodic

lubrication is recommended.

Greasing the Slack Adjuster

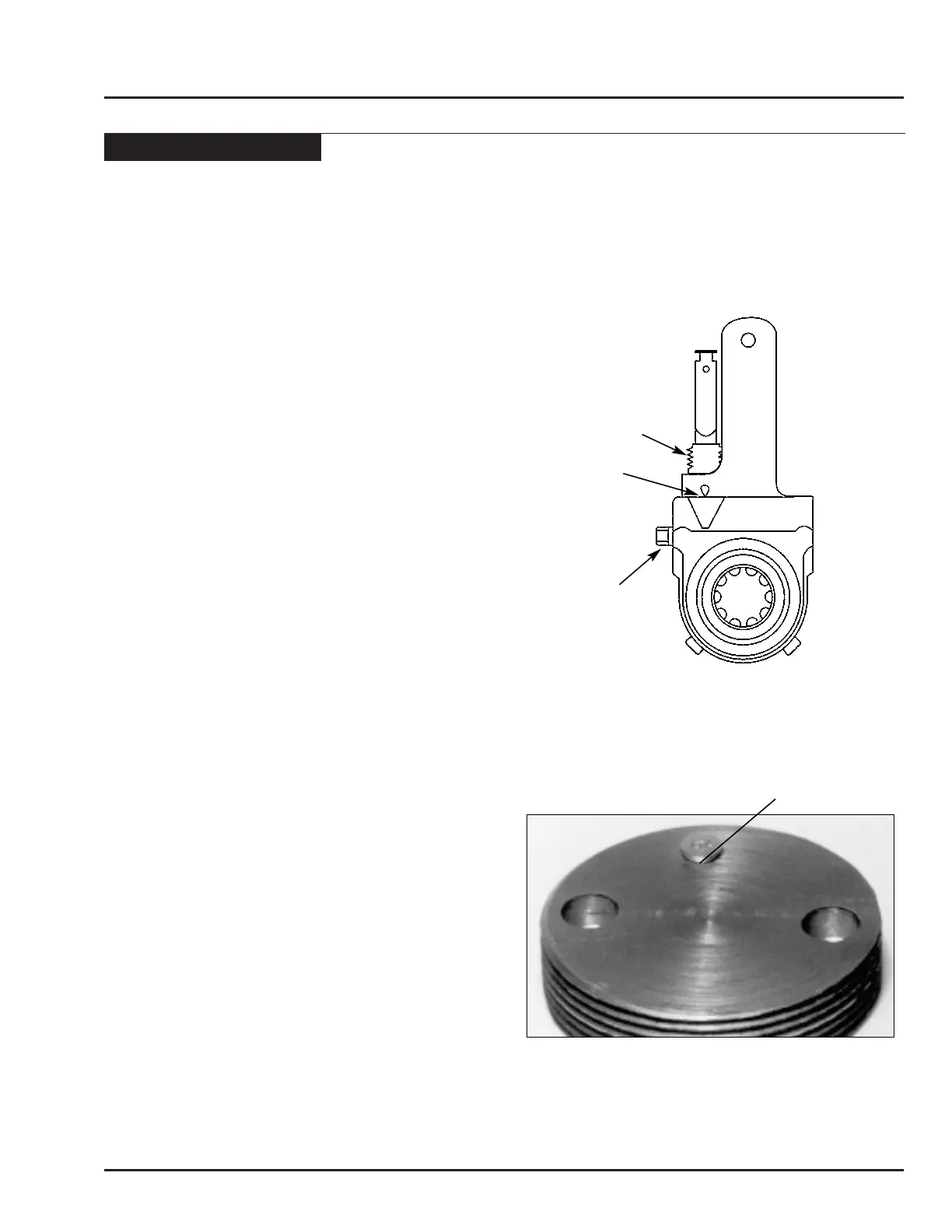

1. A grease fitting is provided to allow lubrication

during normal chassis servicing (see g. 1). With

a conventional grease gun, lubricate until grease

appears on the camshaft, or grease ows from the

grease relief.

Note: Slack Adjusters with a grooved and drilled

worm wheel will not have a grease relief on

the end cap opposite the adjusting hex.

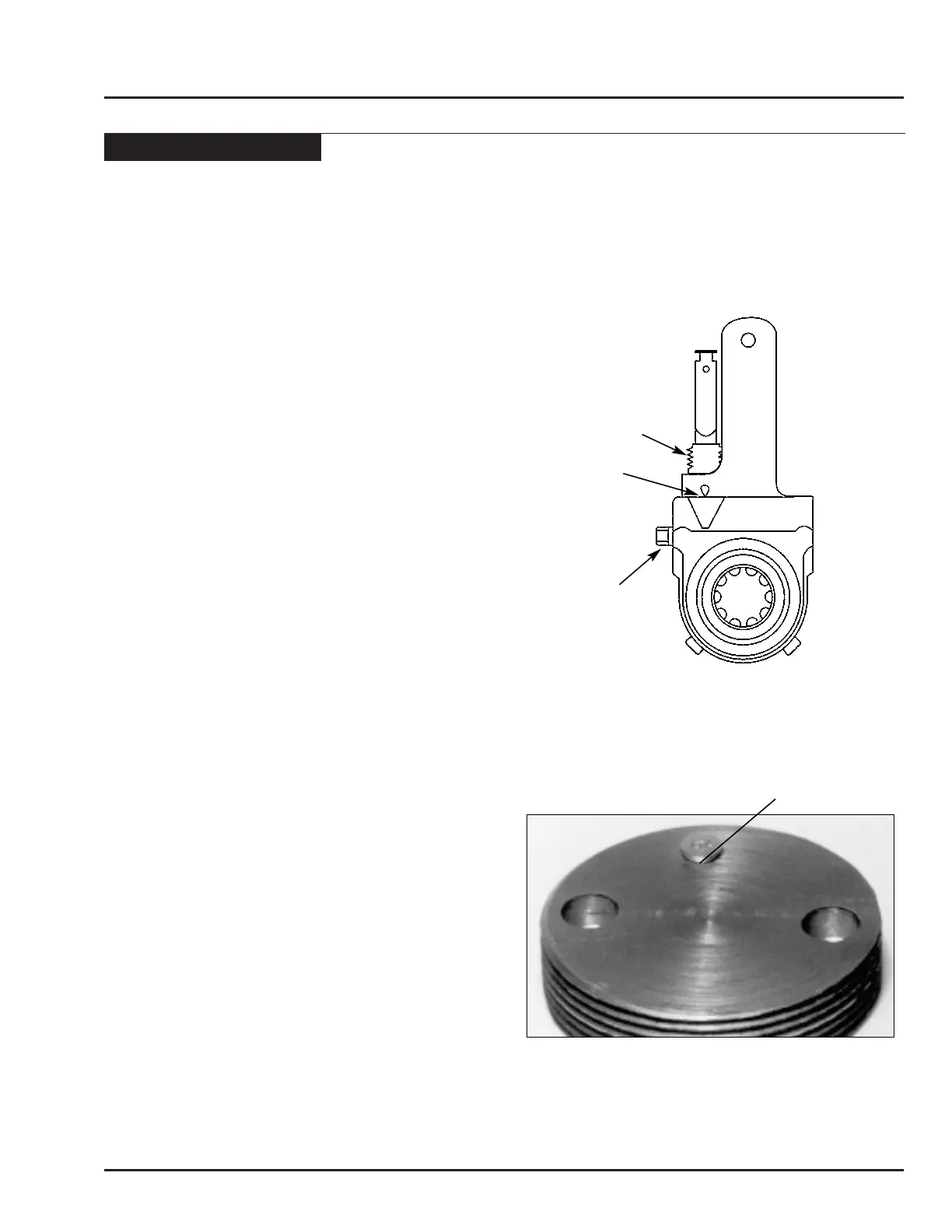

2. The newest Gunite slack adjusters are produced

without a grease relief, forcing lubricant through

the drilled worm wheel onto the camshaft. Previous

designs incorporated a grease relief (see g. 2).

3. Lubriplate Aero is the grease used in the manufacture

of Gunite slack adjusters. It is recommended for

use in temperatures as low as -40 degrees F (-40

degrees C).

Boot

Grease

Fitting

Hex

Extension

Figure 1 - Lubrication Points

Grease Relief

Figure 2 - Grease Relief

Loading...

Loading...