4-27

Adjusting Leveling and Final Stop

iControl AC

4

• Brake Coordination for Smooth Stops - Proper operation and setting of the brake is

very important to achieve a smooth stop:

1. Before starting, the brake must be operating properly. Geared machine brakes are usu-

ally very simple, however, the brake on a gearless machine requires detailed adjustment

to obtain proper operation. For now, be sure to adjust brake tension to hold 125% of a

rated load (or the value required by your local code authorities). To establish a holding

voltage for a brake in a geared installation, refer to the manufacturers recommended

value. If this information is not available, experiment with the Hold Voltage (Brake Con-

figuration/Voltage tab) to find the voltage necessary to hold the brake and then add a lit-

tle extra margin.

2. If you have already adjusted the brake to the correct mechanical clearances and the

brake is still clunking down too hard when the car stops, increase Voltage Decay Time

(Configuration > Brake > Control tab (iField module, high current braking only). For

low current brakes, decrease the RB resistance inside the iPower Box.

3. Next, adjust Drop Delay (Configuration > Brake > Control tab) so that the brake drops

the instant hoist motor motion stops. The primary means of coordinating brake drop

with motion stop is adjusting Brake Drop Delay. The initial setting should be 0.00 sec-

onds. Increase Drop Delay in increments of 0.10 second until the motor is clearly at zero

speed when the brake drops. The goal is to avoid dropping the brake on a moving motor,

but also to avoid holding the brake up longer than necessary.

• TORQMAX drive - For TORQMAX F5 v3.xx, LT12 Current Hold Time must be set to

0.0 seconds. For TORQMAX F5 v1.71, adjust LF.78 Current Hold Time (delay in turn-

ing off the motor current after direction is dropped), which can hold the car electrically

until the brake is dropped. Start with a setting of LF,78 = 0.50 seconds.

4. Adjust Voltage Decay Time to determine how softly the brake drops (higher values yield

softer drop). If Voltage Decay Time is set too high, there will be loss of control during the

time between the drive “disconnecting” and the brake setting firmly.

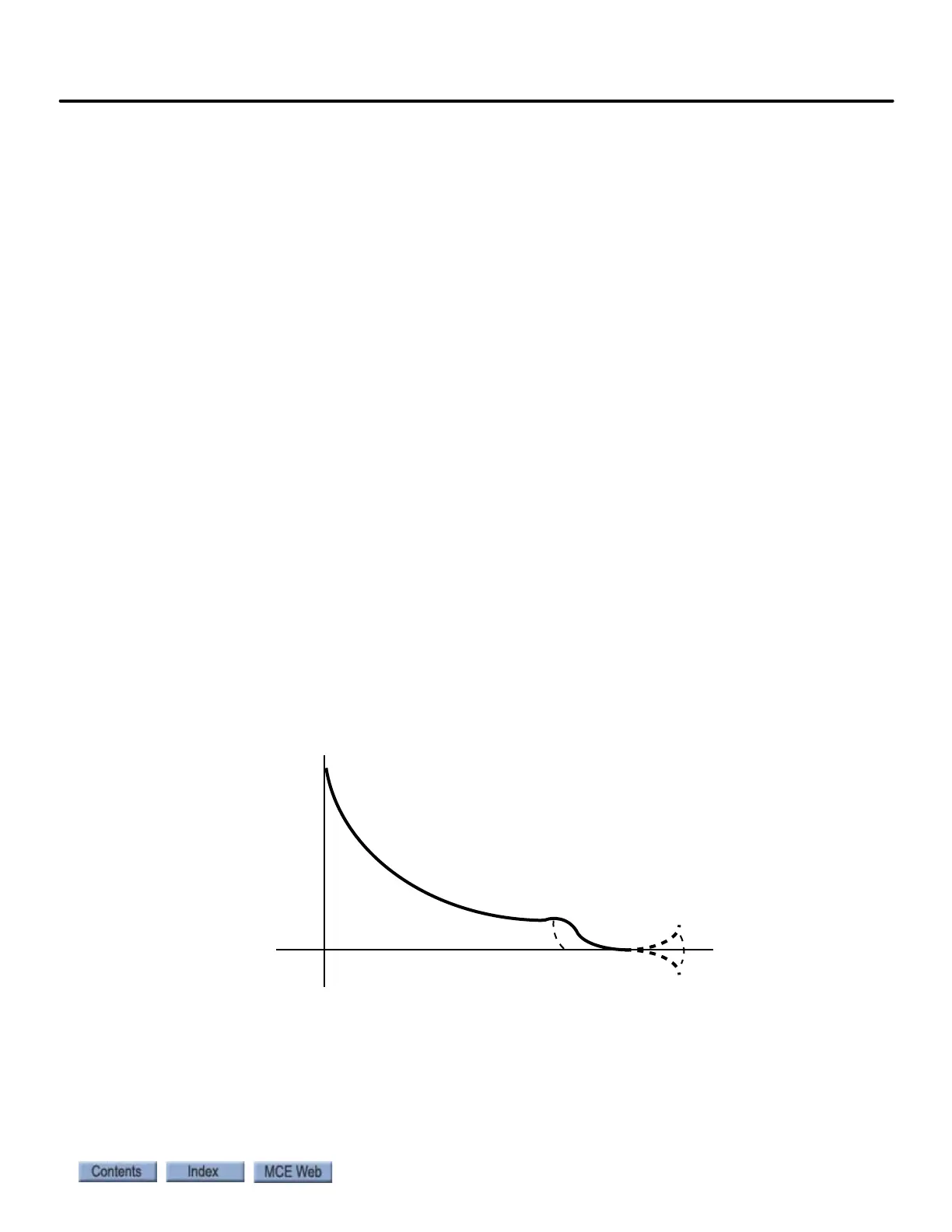

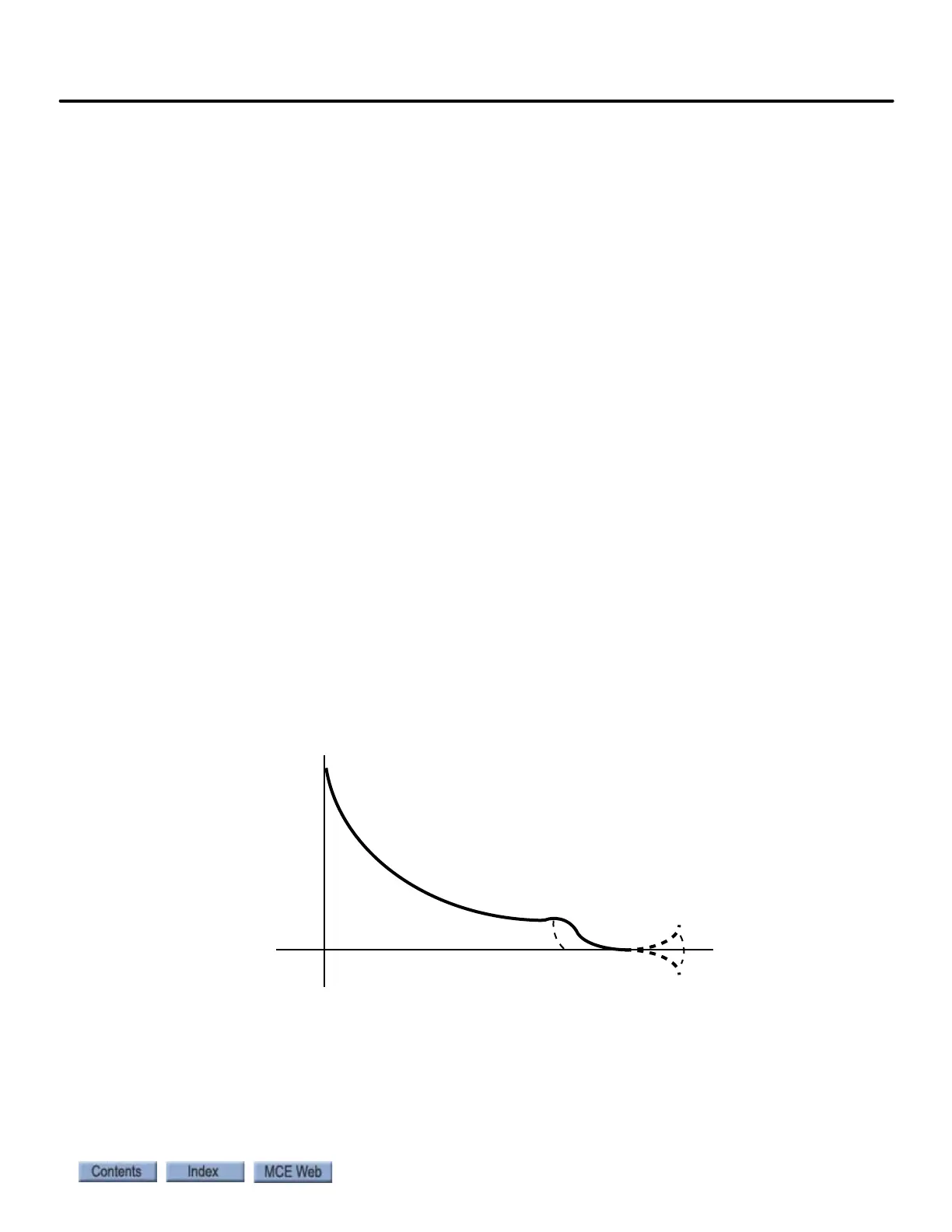

Figure 4.5 Effect of Brake Drop Delay on Stopping

Drop Delay just right

Too much Drop Delay

Not enough Drop Delay

Speed Feedback

Time

Loading...

Loading...