Installation

3-9

Part 1079832_04

E 2015 Nordson Corporation

Applicator Flushing

Flushing the applicator removes cleaning solution, adhesive, and other

contaminants from the equipment. The applicator should be flushed before

initial use and anytime you change the adhesive in the hot melt system. This

helps prevent clogging of the filter or nozzles and makes the applicator work

more efficiently.

Prepare for Applicator Flushing

1. Determine whether you need to flush the applicator with adhesive or with

cleaning fluid and then with adhesive. Refer to Table 3‐1.

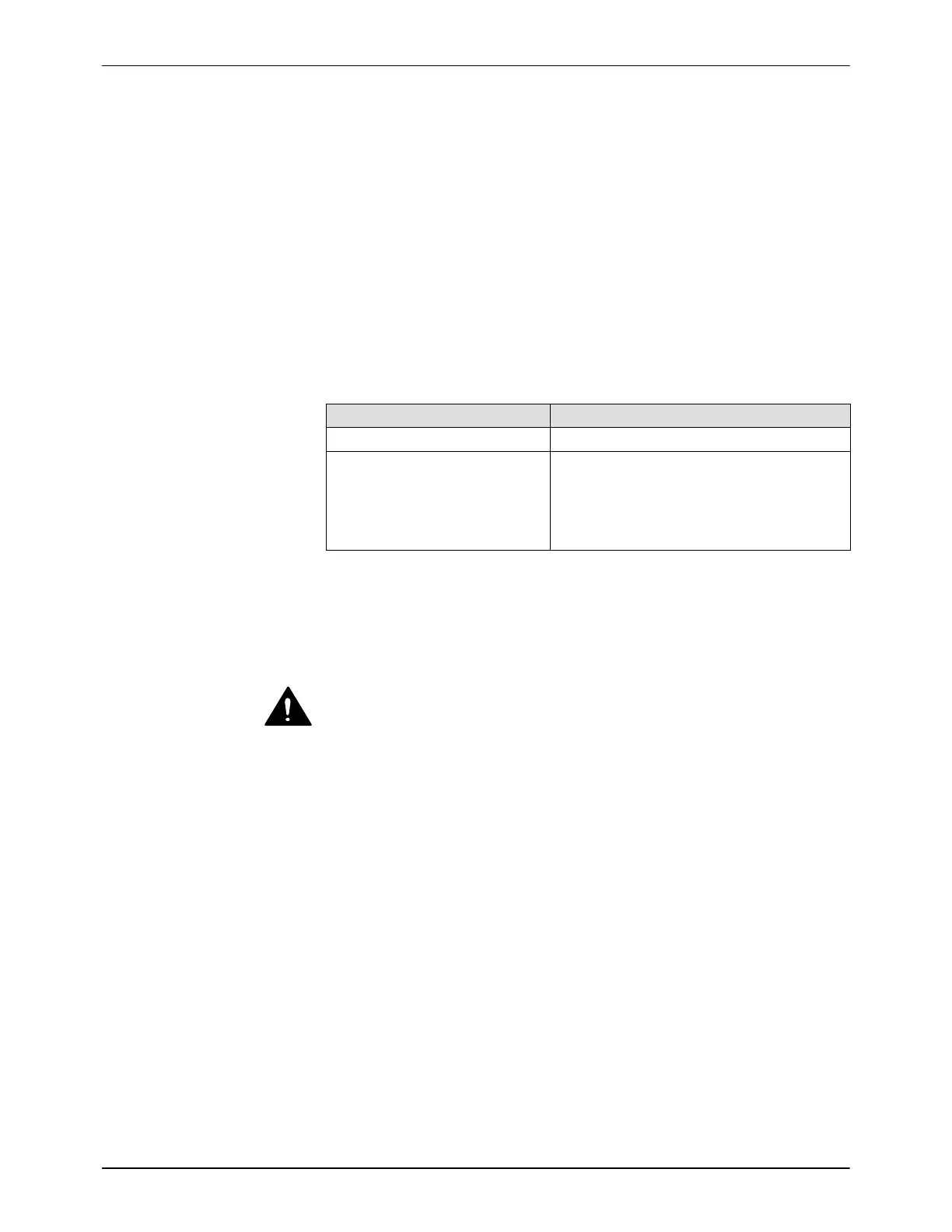

Table 3-1 Applicator Flushing Situations

Situation Flushing Materials to Use

Initial startup Adhesive only

Changing adhesive in the

system

a. Cleaning solution compatible with

both the old and new adhesives

b. New adhesive (to remove the

cleaning solution)

2. Heat the system to application temperature. Refer to the melter manual

as needed.

3. Stop the melter pump(s).

4. Place drain pans under the applicator drain valves, the hose connections,

and the modules.

WARNING! Risk of burns. Failure to relieve system pressure can cause hot

adhesive to spray from a connecting point. Relieve system pressure before

loosening or removing a hose, module, or any other part of the hot melt

system. Wear heat‐protective clothing, safety goggles (ANSI Z87.1 or

equivalent), and safety gloves.

5. Relieve system pressure. Refer to Relieving System Pressure in

Section10, Filter.

6. Flush the applicator by performing the following procedures with each

flushing material to be used:

S Flush the Hose

S Flush the Filter

S Flush the Manifold

S Flush the Modules

Loading...

Loading...