Module

9-2

Part 1079832_04

E 2015 Nordson Corporation

Module Overview

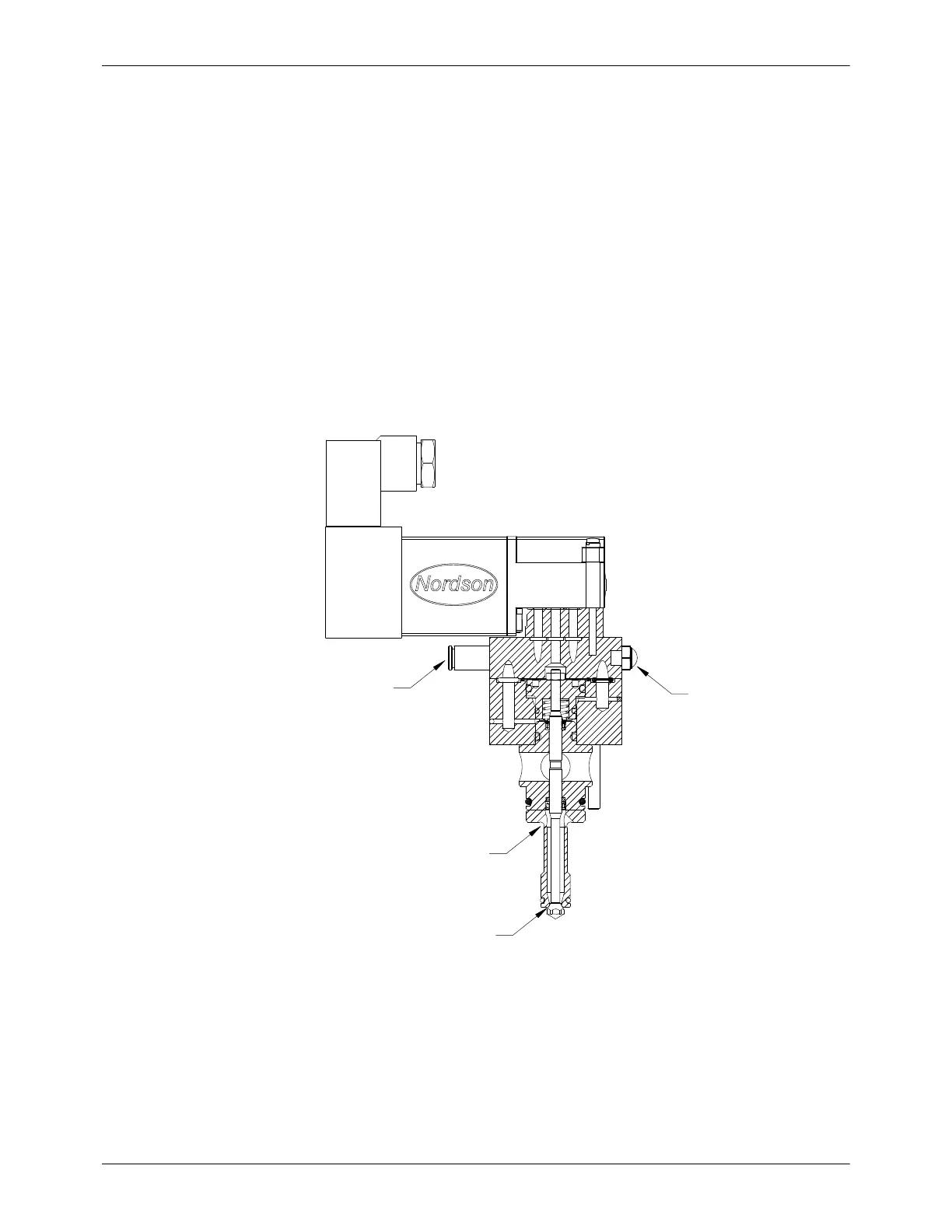

Dispensing modules apply adhesive to a product. A Speed‐Coat control

module is air‐actuated, meaning that an air supply controlled by a solenoid

valve is required to operate the module. To supply adhesive to the nozzle,

pressurized air (module‐actuating air) lowers the nozzle stem, allowing

adhesive to flow through the nozzle onto the product. To stop the flow of

adhesive, the pressurized air is removed and the nozzle stem moves

upward, pulling the adhesive back into the module and ensuring clean cutoff.

A separate air supply is used to supply pattern air to the module; this air

enters the pattern air inlet on the applicator body and is directed onto the

adhesive exiting the nozzle, creating the desired spray pattern.

Figure 9‐2 shows the flow of adhesive and air through a Speed‐Coat control

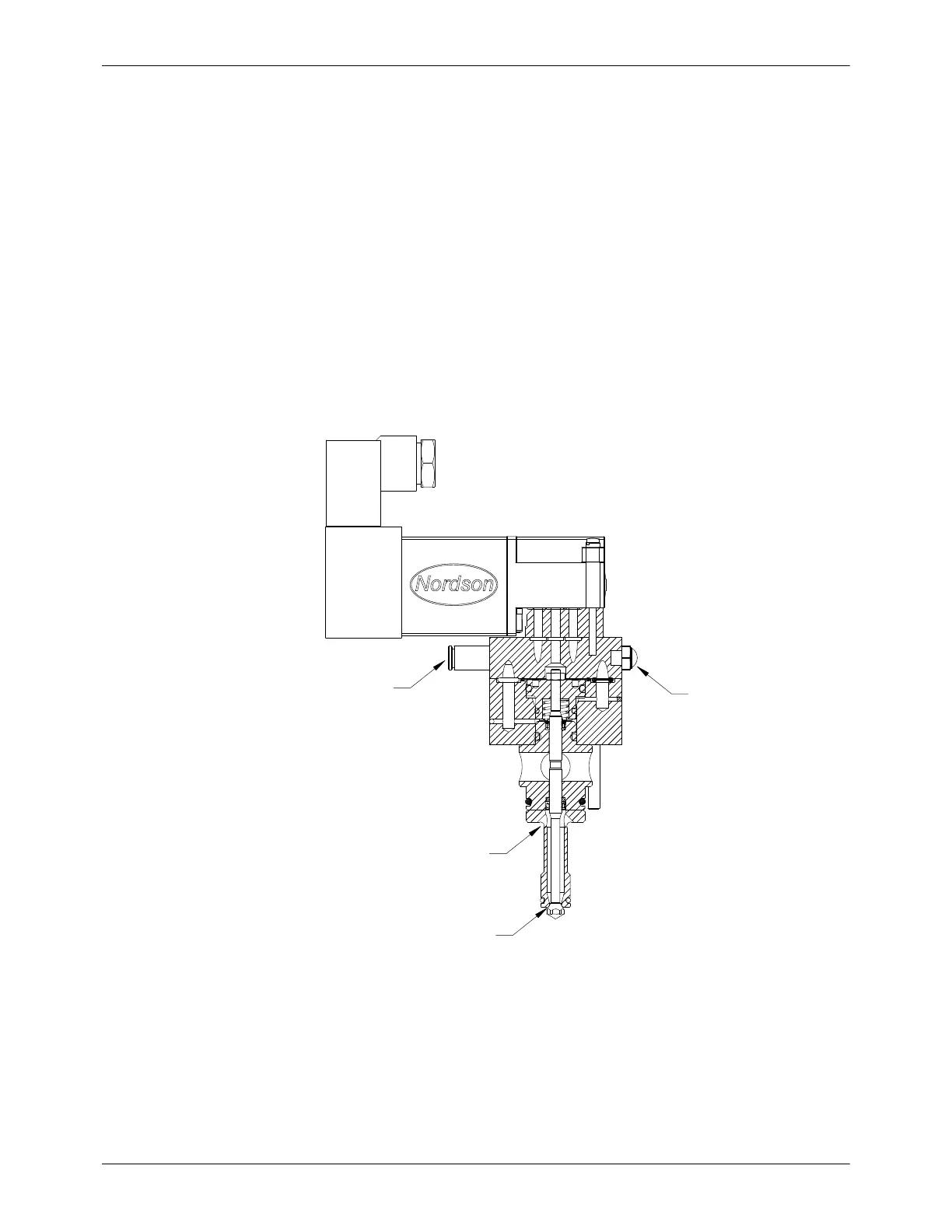

module. Figure9‐3 shows the key parts of a Universal Speed‐Coat module.

Actuation

air inlet

Adhesive

inlet

Air exhaust

Adhesive

outlet

Figure 9-2 Flow of adhesive and air through a Speed-Coat control module

Loading...

Loading...