Maintenance

5-2

Part 1079832_04

E 2015 Nordson Corporation

Recommended Maintenance Schedule

Table 5‐1 provides a list of recommended maintenance activities. Base how

often you perform these activities on your specific operating needs. The

frequency shown is for reference only.

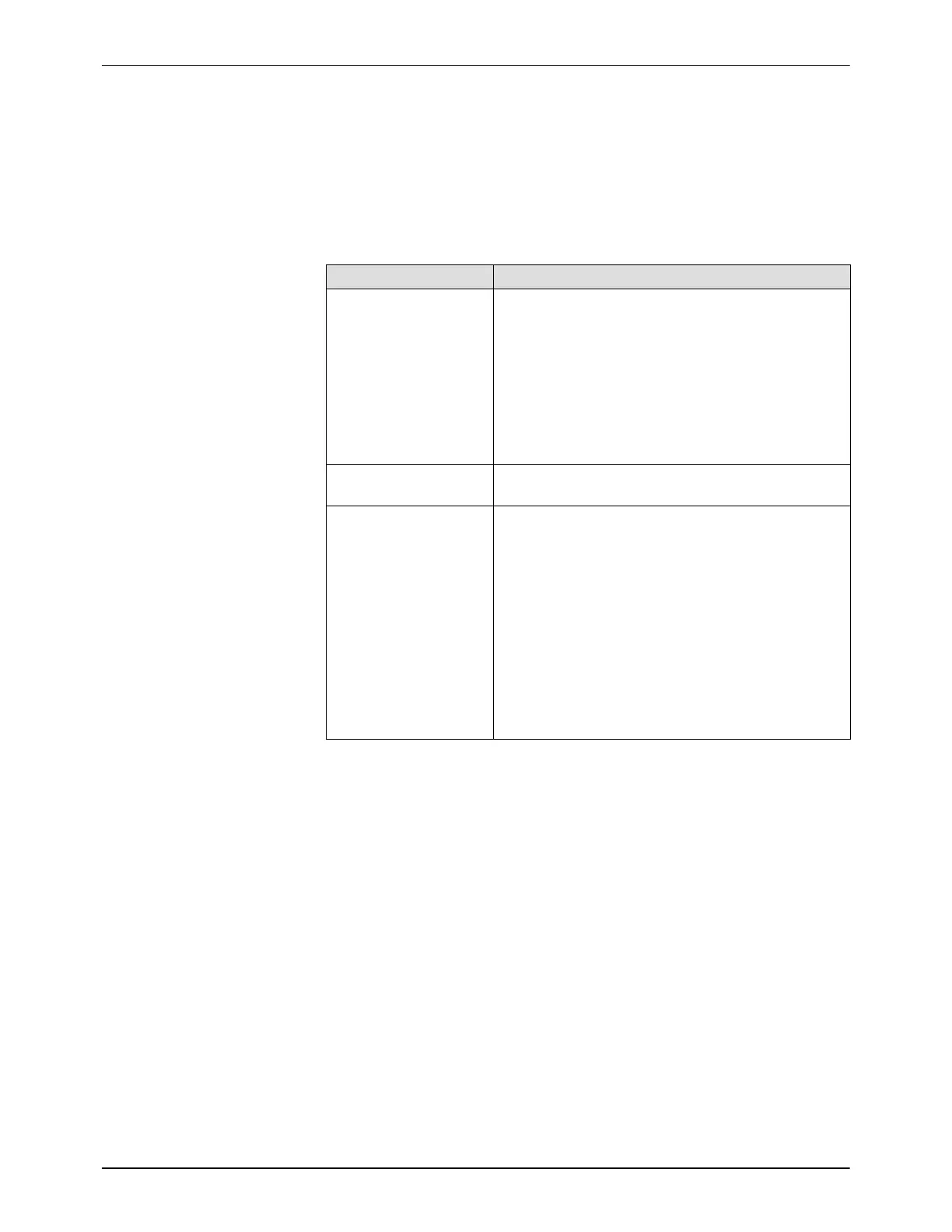

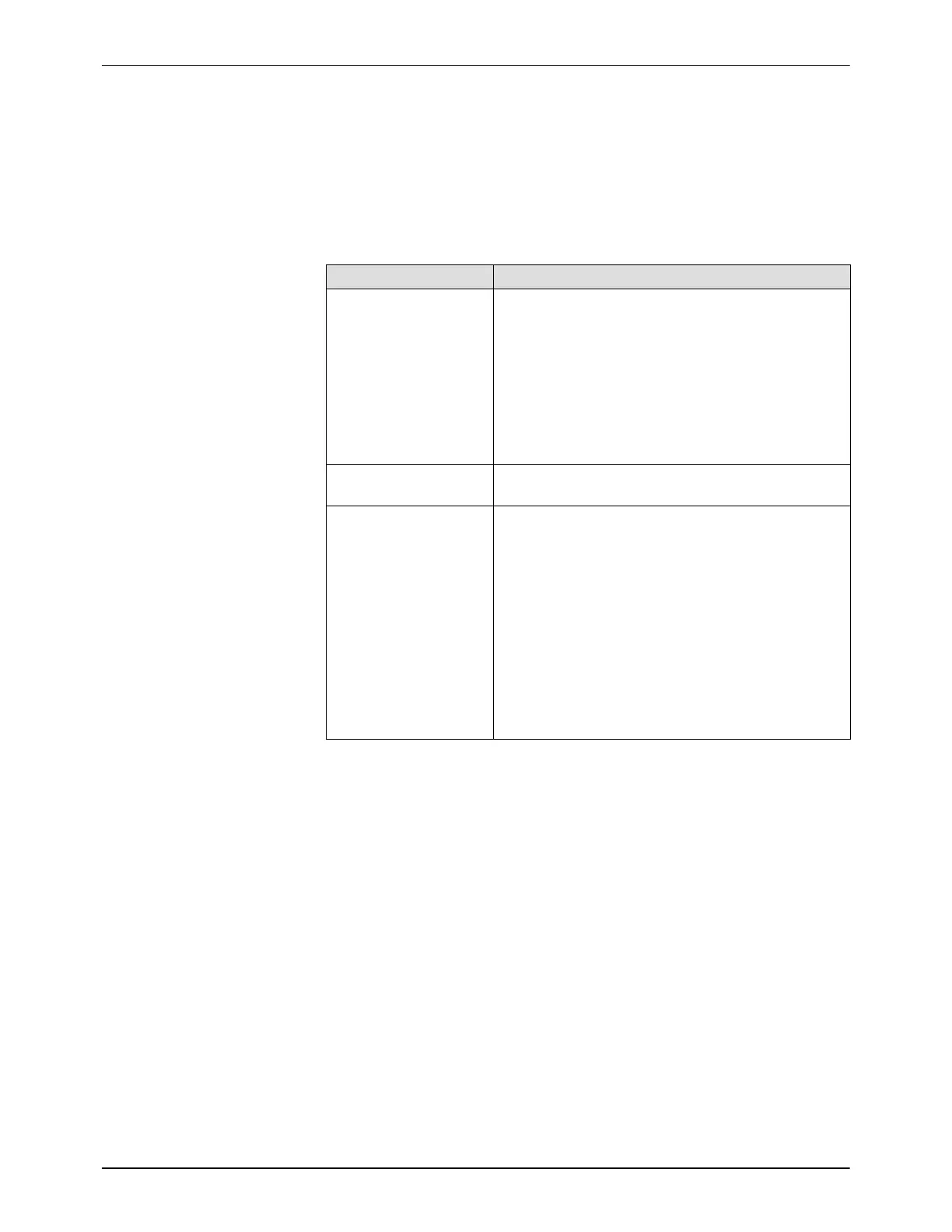

Table 5-1 Recommended Maintenance Schedule

Frequency Maintenance Activity

Daily

S Keep the supply of adhesive clean and free

of contaminants. Foreign particles in the

adhesive can clog the filter or nozzles.

S Clean all exterior applicator surfaces.

Accumulated adhesive can char and cause

erratic operation.

S Check the hose connections for leaks. If a

leak is found, replace the hose fitting and/or

O-ring as appropriate.

Weekly

S Clean nozzles. Refer to the nozzle cleaning

procedure in Section 9, Module.

As needed

S Replace the filter screen. Refer to the filter

screen replacement procedure in Section 10,

Filter.

S Verify that all electrical connections are

secure. Vibration and heating or cooling

cycles can loosen wire nuts and terminal

blocks.

S Clean the air pressure regulator filter

elements. Refer to the air pressure regulator

documentation.

S Clean the system. Refer to the system

cleaning procedure in the melter manual.

Loading...

Loading...