Troubleshooting

6-2

Part 1079832_04

E 2015 Nordson Corporation

Applicator Heating Problems

Refer to this troubleshooting table if the applicator does not heat, underheats,

or overheats.

NOTE: Each heated component in a hot melt system (typically the grid, the

reservoir, each hose, and each applicator) is referred to as a heated zone.

The applicator's heated zones are the adhesive manifold and the heated air

manifold. Some applicators may have multiple adhesive manifold and heated

air manifold zones.

WARNING! Risk of personal injury or death. Allow only qualified personnel to

perform electrical installation, troubleshooting, or repair procedures. Before

performing any electrical procedure, review Section 1, Safety, and

disconnect and lock out electrical power to the system.

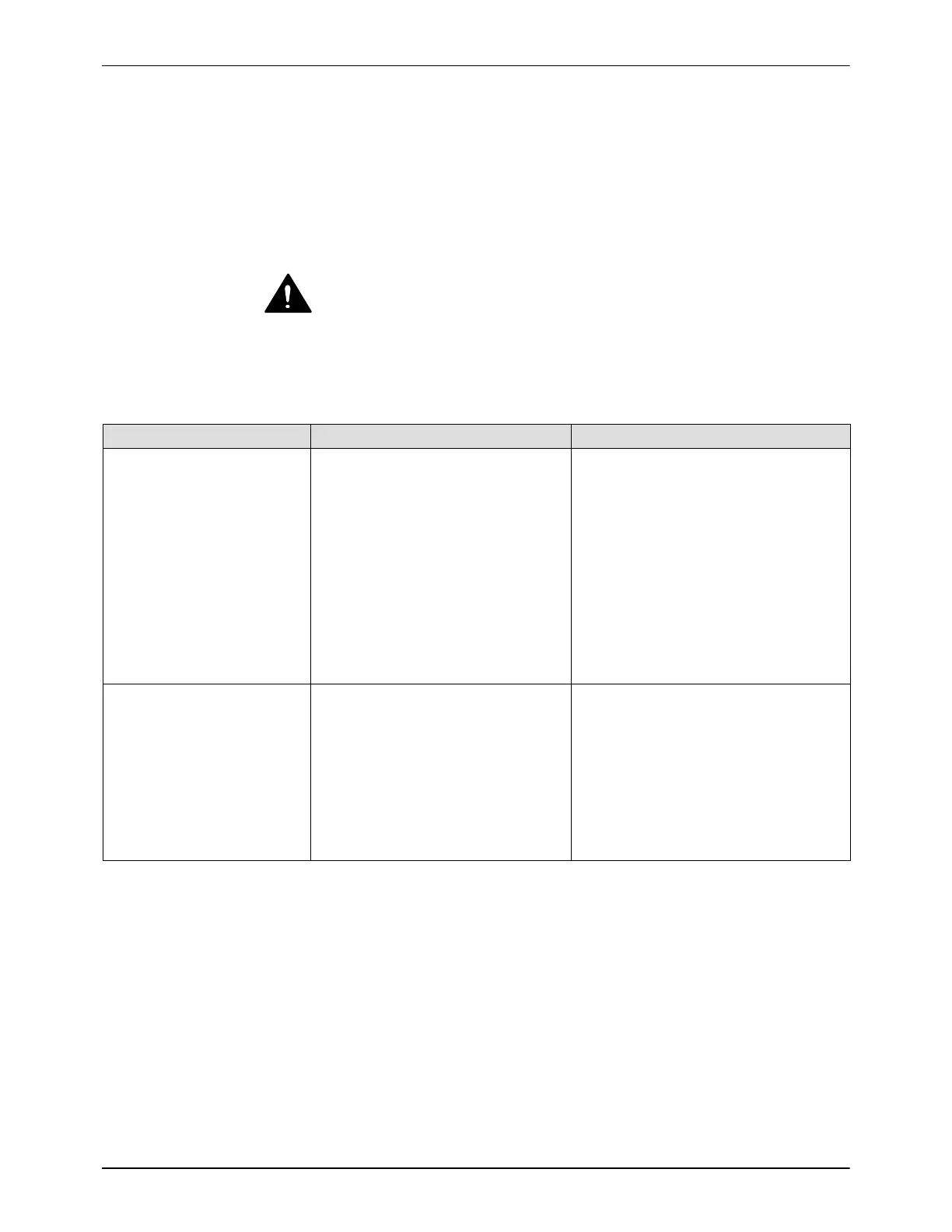

Problem Possible Cause Corrective Action

1. Applicator does not

heat

System power not on Verify that the system power is turned

on.

Loose electrical connection Verify that all electrical connections

(cordsets and cables) at the melter

and the applicator ends of the hose

are secure.

Broken or missing electrical pins Check for broken or missing pins at

all electrical connections. Repair or

replace damaged components.

Adhesive or heated air manifold

temperature setpoints too low

Adjust the temperature setpoints as

necessary. Refer to the melter or

temperature controller manual.

2. Applicator underheats

or overheats

System in standby or setback

mode

Take the system out of standby or

setback mode.

Adhesive manifold, heated air

manifold, or hose temperature

setpoints too low or too high

Adjust the temperature setpoints as

necessary. Refer to the melter or

temperature controller manual.

Failed heater, sensor (RTD or

thermocouple), or cable

Check the heaters, sensors, and

cables for the problem zone. Refer to

the appropriate procedures in

Section 11, Electrical System.

Loading...

Loading...