Filter

10-1

Part 1079832_04

E 2015 Nordson Corporation

Section 10

Filter

WARNING! Allow only personnel with appropriate training and experience to

operate or service the equipment. The use of untrained or inexperienced

personnel to operate or service the equipment can result in injury, including

death, to themselves and others, and damage to the equipment.

Introduction

This section provides maintenance/repair and parts information for

applicators with a Universal in‐out adhesive filter.

Filter Overview

The filter is located in the adhesive manifold portion of the applicator and is

screwed into the top of the applicator. A top‐loading filter is referred to as a

vertical filter.

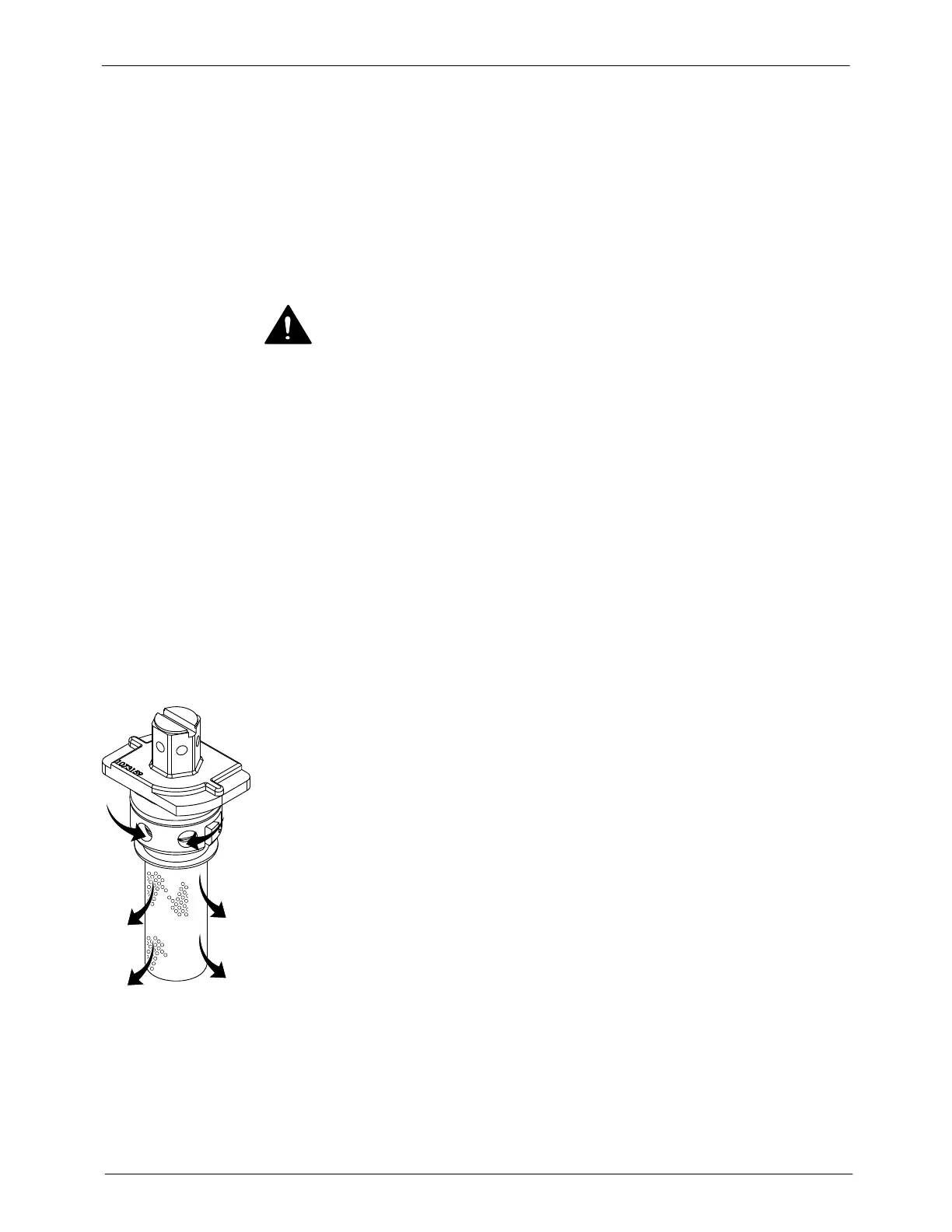

When adhesive enters the applicator manifold, it flows from the inside of the

filter to the outside (in‐out), as shown in Figure10‐1, before it is directed

towards the dispensing modules. This causes char and debris to collect on

the inside of the filter screen.

The filter must be periodically flushed to remove the char and debris from the

inside of the screen. When flushing fails to clean the filter screen adequately,

it should be replaced.

Figure 10-1 Flow of adhesive

through a Universal

in-out filter

Loading...

Loading...