Solver NEXT SPM. Instruction Manual

196

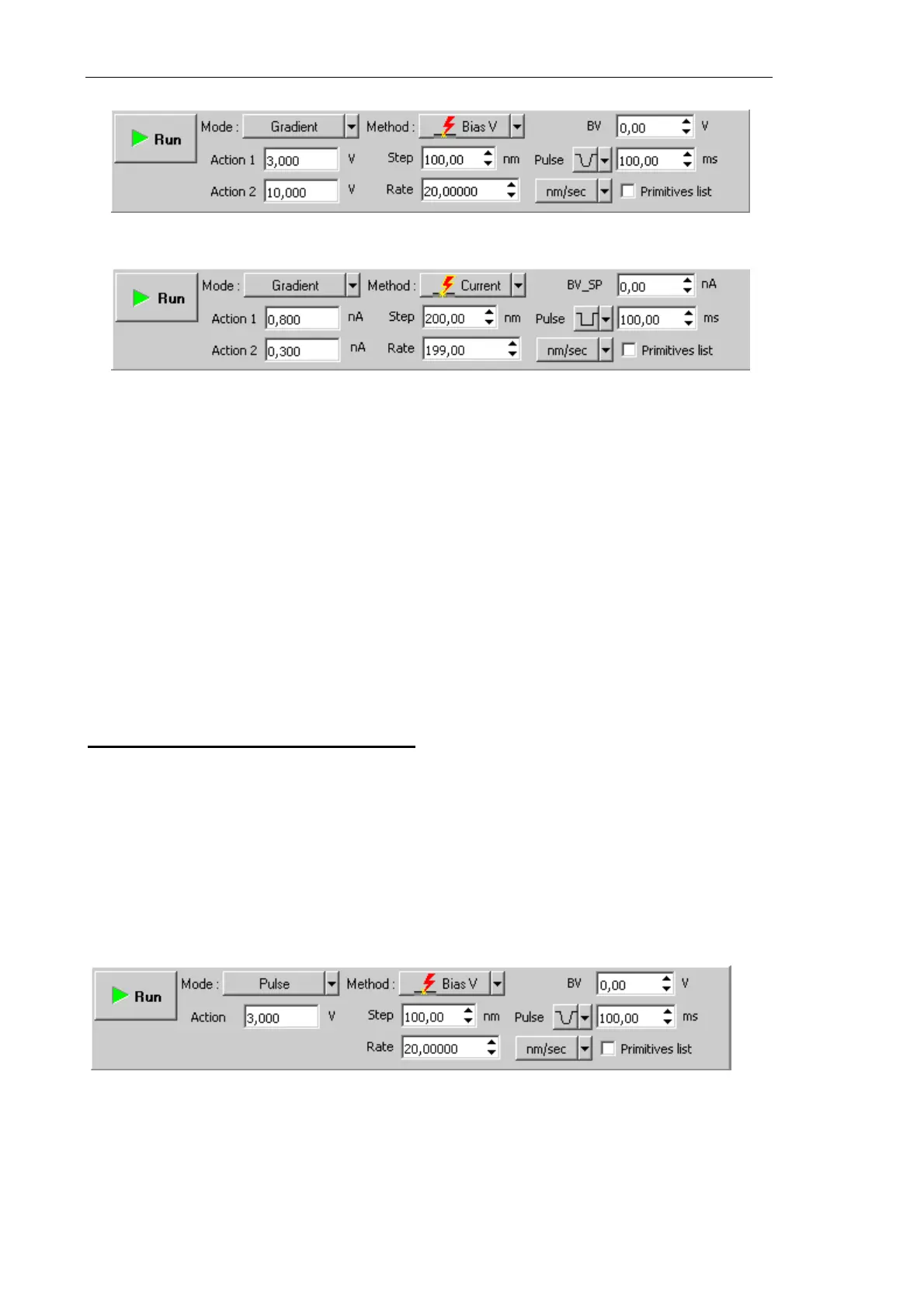

Fig. 8-48. Control panel for Charge lithography

Fig. 8-49. Control panel for Current lithography

3. In the SetPoint field, define the exposure to be applied to the sample when the probe

moves to starting points of the template objects after finishing drawing or at the start of

lithography. For current lithography, the BV field is used; for current lithography, the

BV_SP field is used. Usually, this level is defined to be 0.

4. In the Rate field, define the lithography rate (the speed of moving the probe relative to

the sample surface).

The lithography rate influences on results of the sample exposure to lithography. The

lower is the rate, the deeper is the exposure and the better is the correspondence

between the template and the resulting surface.

NOTE. The parameters

Step

and

Pulse

are irrelevant for the Gradient vector lithography.

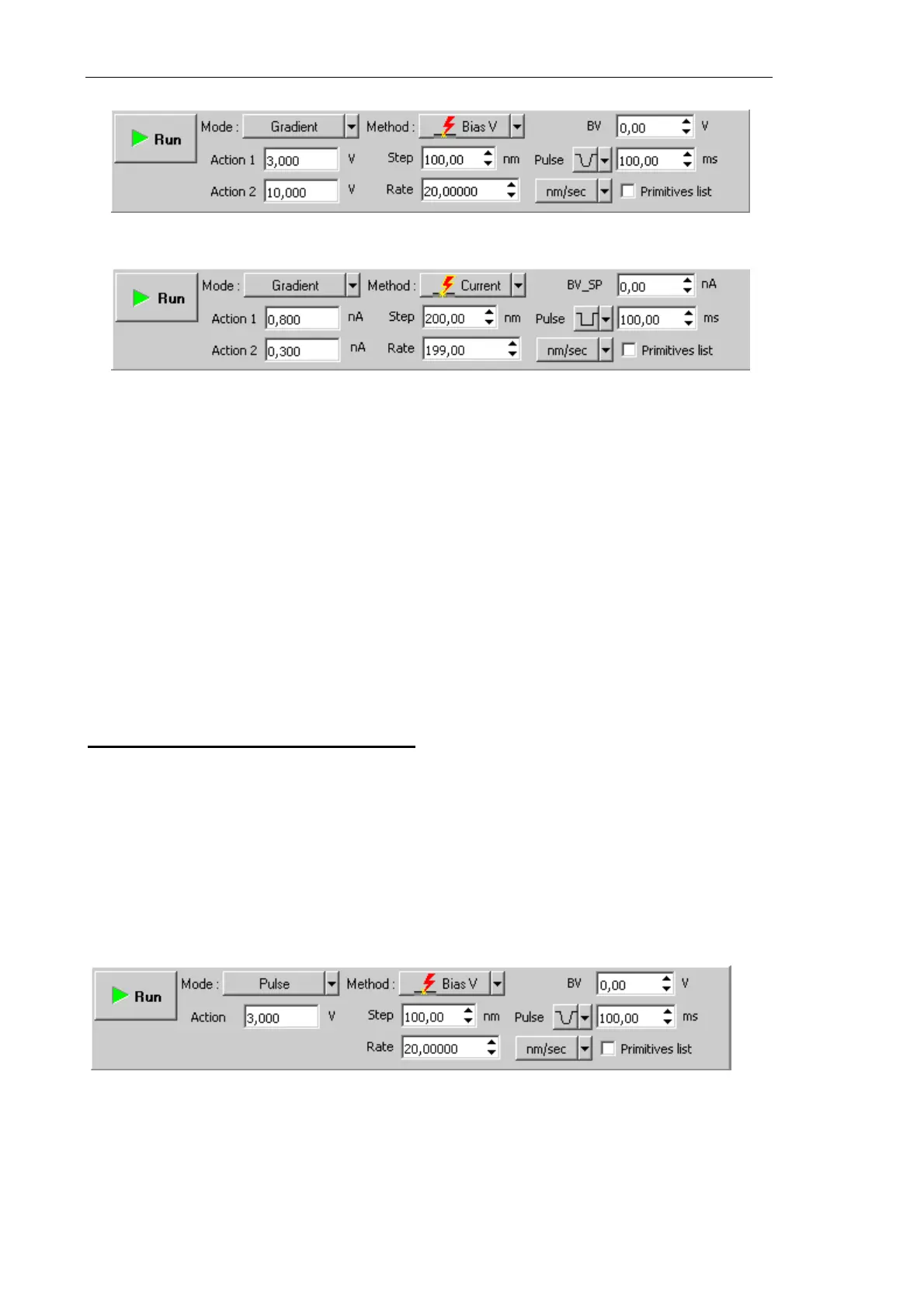

Adjusting Pulse Lithography Parameters

1. Decrease the level

SetPoint window by a factor of 2÷10 relatively to the SetPoint level

used for scanning.

2. In the Action field of the lithography Control panel, define the exposure level to be

applied to the sample during drawing the template objects (Fig. 8-22).

Sign of the applied voltage influences significantly results of lithography. For example,

at large negative (<–8 V) voltage applied to the probe tip (

Action parameter),

lithography can result not only in surface charging but also in local oxidation.

Fig. 8-50. Control panel for Charge lithography

Loading...

Loading...