Multi-function Compact Inverter 3G3MX2-EV2 User’s Manual (I666-E1)

Precautions for Correct Use

•

Setting the Motor Electronic Thermal Selection (b910) to 01 to 03 separates the inverter from

the motor electronic thermal function. This enables you to change the operation characteris-

tics of the motor electronic thermal function according to the thermal time constant of the

motor in use. For how to change these characteristics, refer to 7-8-2 Motor Electronic Ther-

mal Function on page 7-74.

•

To comply with UL standards, set the Electronic Thermal Load Rate Memory Selection at

Power-off (b914) to 01 (Enabled).

•

To set the electronic thermal function to work as with the conventional 3G3MX2 Series, set

the Motor Electronic Thermal Selection (b910) to 00 (Disabled).

•

To connect several motors to a single inverter, set the Electronic Thermal Level to the rated

output current of the inverter and install a thermal relay etc. for each motor.

•

Before setting the electronic thermal function, set the 1st/2nd Motor Capacity (H003/H203)

and the 1st/2nd Motor Pole Number (H004/H204) correctly according to your motor.

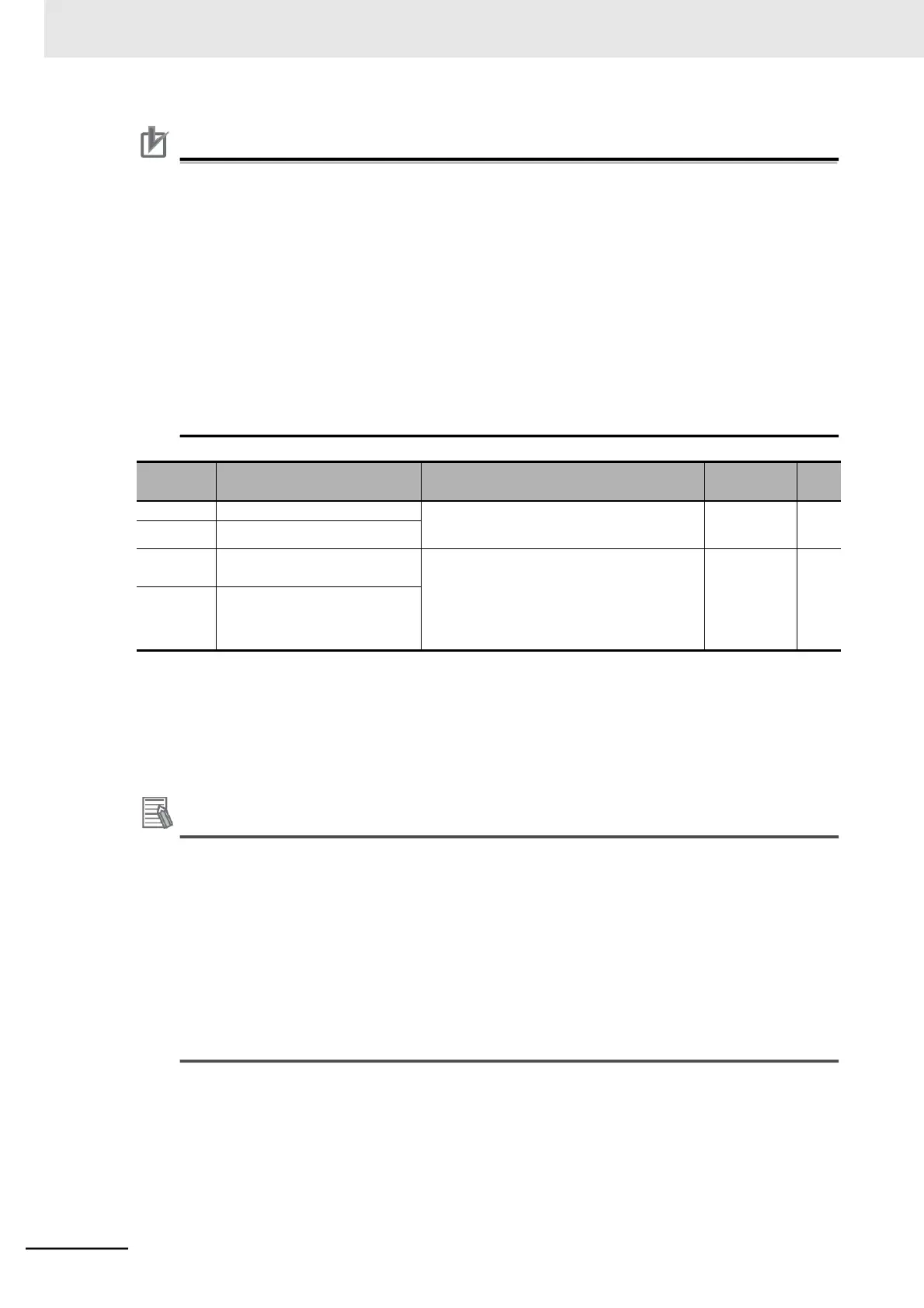

1st Electronic Thermal Level

0.20 Rated current to 1.00 Rated current

*1

Rated

current of

inverter

2nd Electronic Thermal Level

*2

1st Electronic Thermal

Characteristics Selection

00: Reduced torque characteristics (for

general-purpose motor)

01: Constant torque characteristics (for

dedicated inverter motor)

02:

Free setting

*3

2nd Electronic Thermal

Characteristics Selection

*2

*1. Set according to the rated current of your motor.

*2. To enable the switching to the 2nd control, allocate one of the Multi-function Input 1 to 7 Selection (C001 to C007)

to 08 (SET) and then turn ON that terminal.

*3. When 02 (Free setting) is set, the inverter performs overload detection based on the free-electronic thermal

function setting described in 7-8-1 Free-electronic Thermal Function on page 7-73.

Additional Information

•

To check the status of the electronic thermal function, use the Electronic Thermal Load Rate

Monitor (d104). An Overload trip (E05) error will occur if the value reaches 100%.

•

This inverter has the free-electronic thermal function. The free-electronic thermal function

allows you to set the reduction factor for overload detection based on your application.

For details, refer to 7-8-1 Free-electronic Thermal Function on page 7-73.

•

The electronic thermal function can output a warning signal before the inverter is stopped by

an overload detection.

The use of a warning signal is effective to reduce the system down time because it enables

you to solve problems previously.

For details, refer to 7-8-3 Electronic Thermal Warning on page 7-77.

Loading...

Loading...