Detailed Braking Resistor Selection

When the usage rate of the braking resistor selected on

the previous page exceeds 10% ED, or when an

extremely large braking torque is required, use the

method below to calculate a regenerative energy and

make your selection.

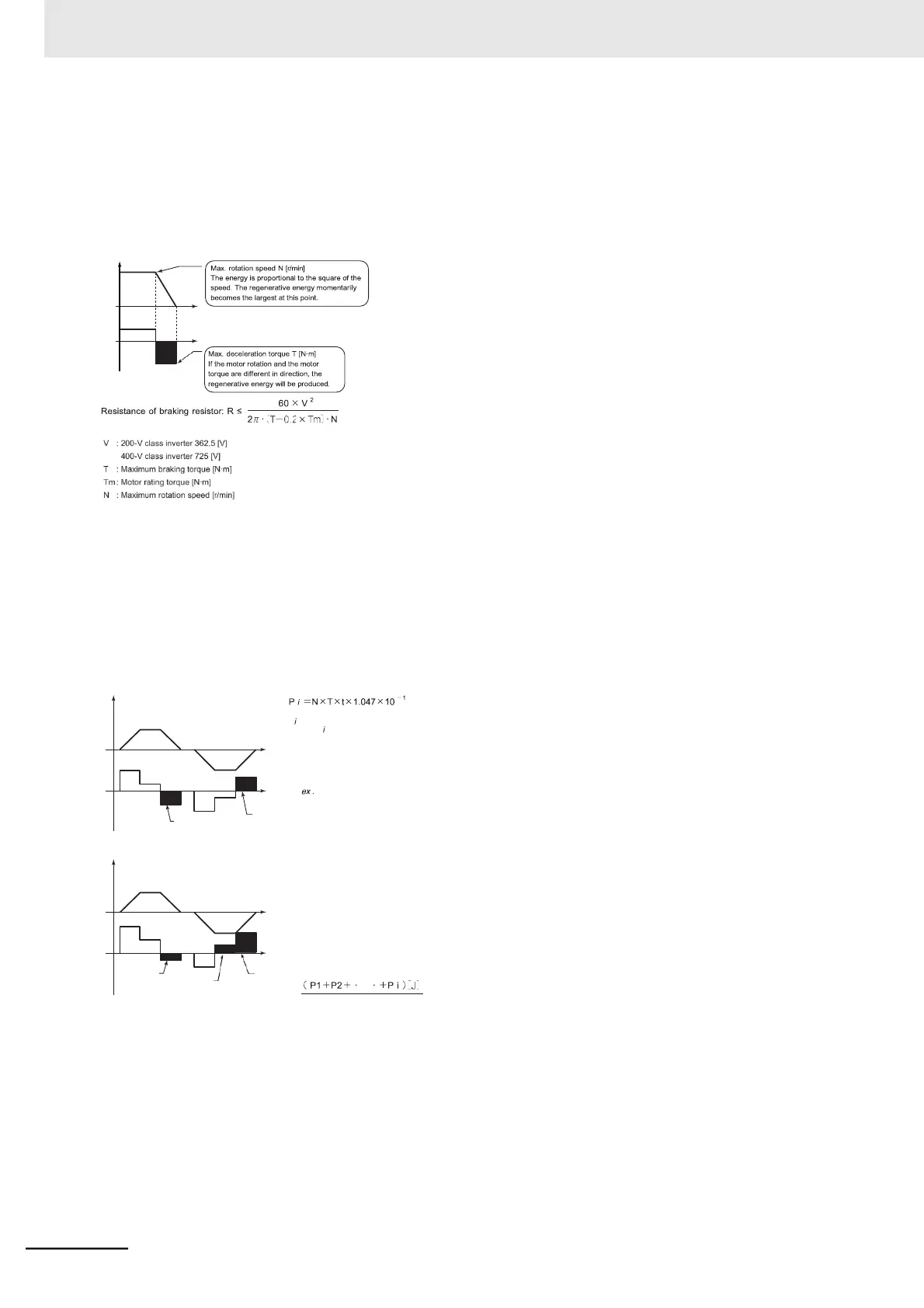

Calculation of Required Braking Resistance

Sp

Braking Resistor Selection

Select a braking resistor from the required braking resistance

and the average regenerative energy described on the left

section.

• Required braking resistance ≥ Resistance of braking

resistor ≥ Min. connection resistance of inverter or

regenerative braking unit

• Average regenerative energy ≤ Resistance capacity of

braking resistor

Tor

Note)

1.

Connecting a braking resistor whose resistance is less than the

minimum connection resistance value of the inverter or regenerative

braking unit results in damage to the internal braking transistor. If the

required braking resistance is less than the minimum connection

resistance, change the inverter or regenerative braking unit to one

having a larger capacity and ensure that the required braking

resistance is not less than the minimum connection resistance.

2.

Two or more regenerative braking units can be connected in parallel.

Refer to the following formula to know the braking resistance value in

such a case: Braking resistance [

] = (Required braking resistance

calculated as above) x (No. of units)

3.

Make allowance for the resistance capacity of the braking resistor.

Select a braking resistor whose capacity is at least 20% larger than

Note: Calculate a braking torque according to Inverter Capacity Selection in

the Motor Capacity Selection section.

the calculated value. Otherwise, it may be overheated.

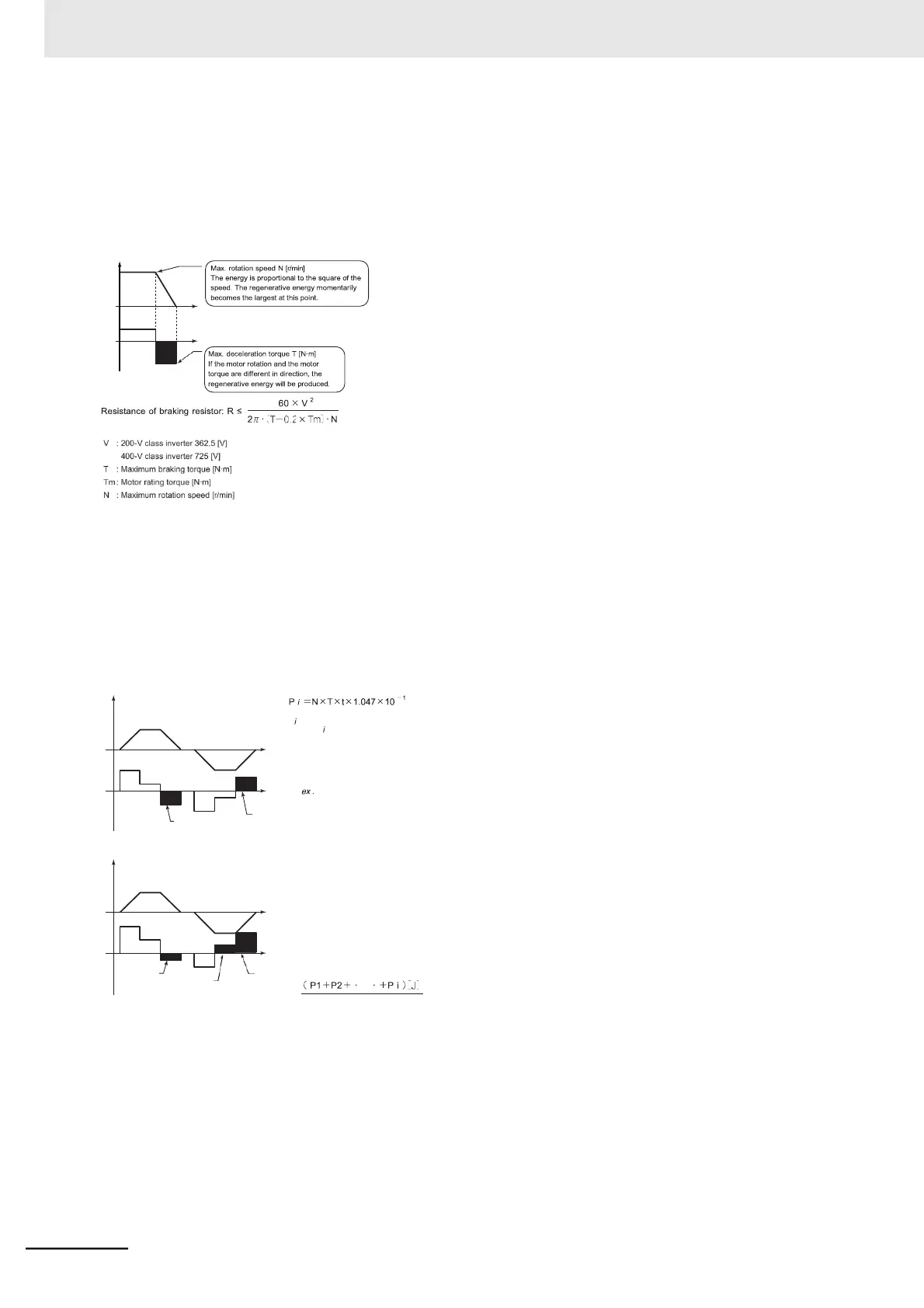

Calculation of average regenerative energy

Regenerative energy is produced when the motor

rotation and the torque are opposite in direction.

Use the following formula to calculate the regenerative

energy for each period in a cycle.

Speed

Torque

For horizontal load

Time

P : Regenerative energy in Period

1 [J]

N: Motor rotation speed [r/min]

When the number of rotations

changes, take an average

value.

For linear deceleration

(N max+N min)/2

Speed

Period 1

For vertical load

Period 2

T: Deceleration torque [N·m]

t:

Deceleration time [s]

• For the average regenerative

energy, calculate the time

average by adding the

regenerative energy for all

periods in a cycle and dividing it

by the cycle time, as shown

below.

Torque

Time

Average regenerative energy [W] =

Period 1

Period 2

Period 3

1 cycle time [s]

Note)

1.

For Speed, the forward rotation direction is indicated as

positive. For Torque, the torque in the forward rotation direction

is indicated as positive.

2.

Calculate a braking torque according to Inverter Capacity

Selection in the Motor Capacity Selection section.

Loading...

Loading...