7.31

FINAL DRIVE

7

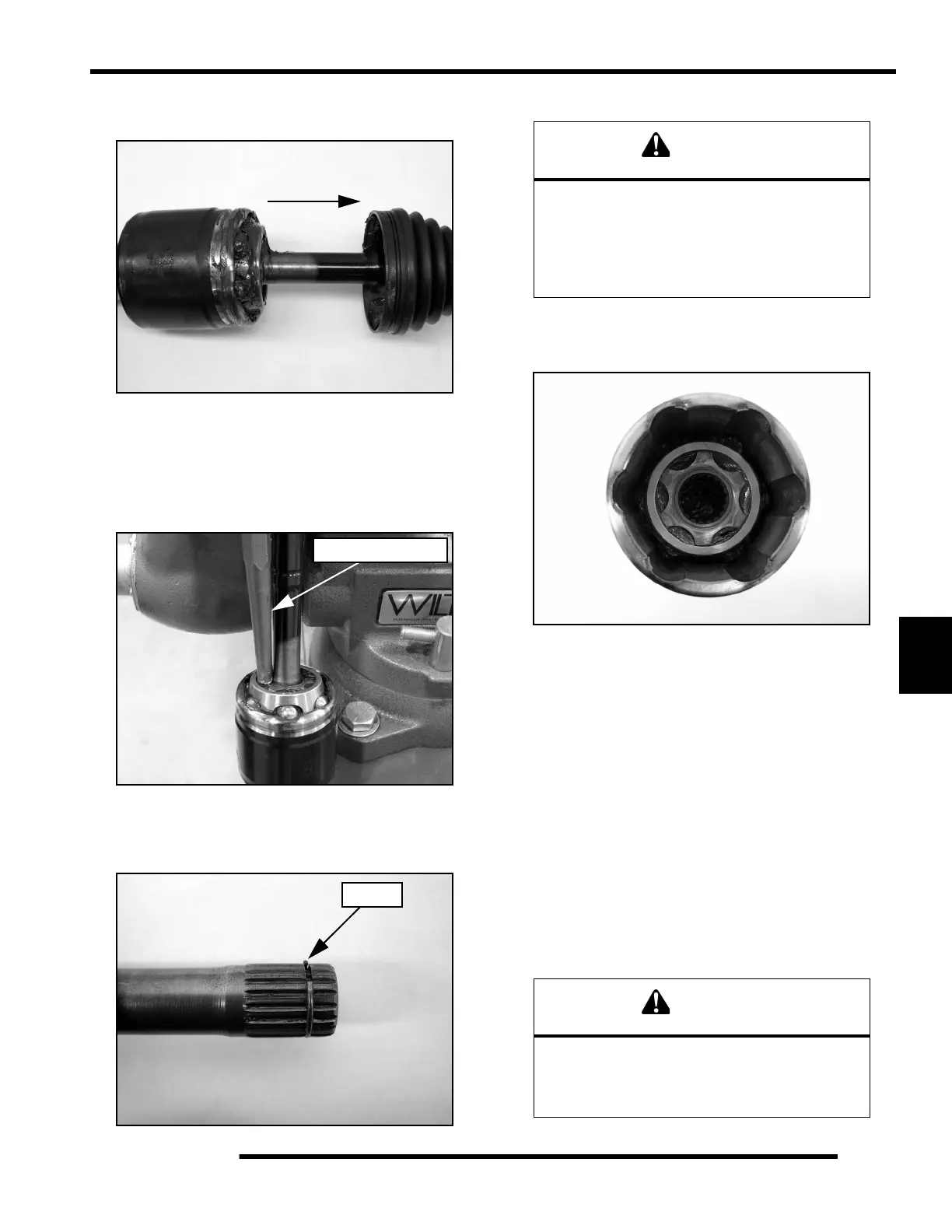

2. Remove the large end of the boot from the plunging joint

and slide the boot down the shaft.

3. Clean the grease from the face of the joint.

4. Place the drive shaft in a soft-jawed vise.

5. Using a soft-faced hammer, or brass drift, strike the inner

race of the joint to drive the joint off the drive shaft. Be sure

to tap evenly around the joint to avoid binding.

IMPORTANT: Tap on inner race only!

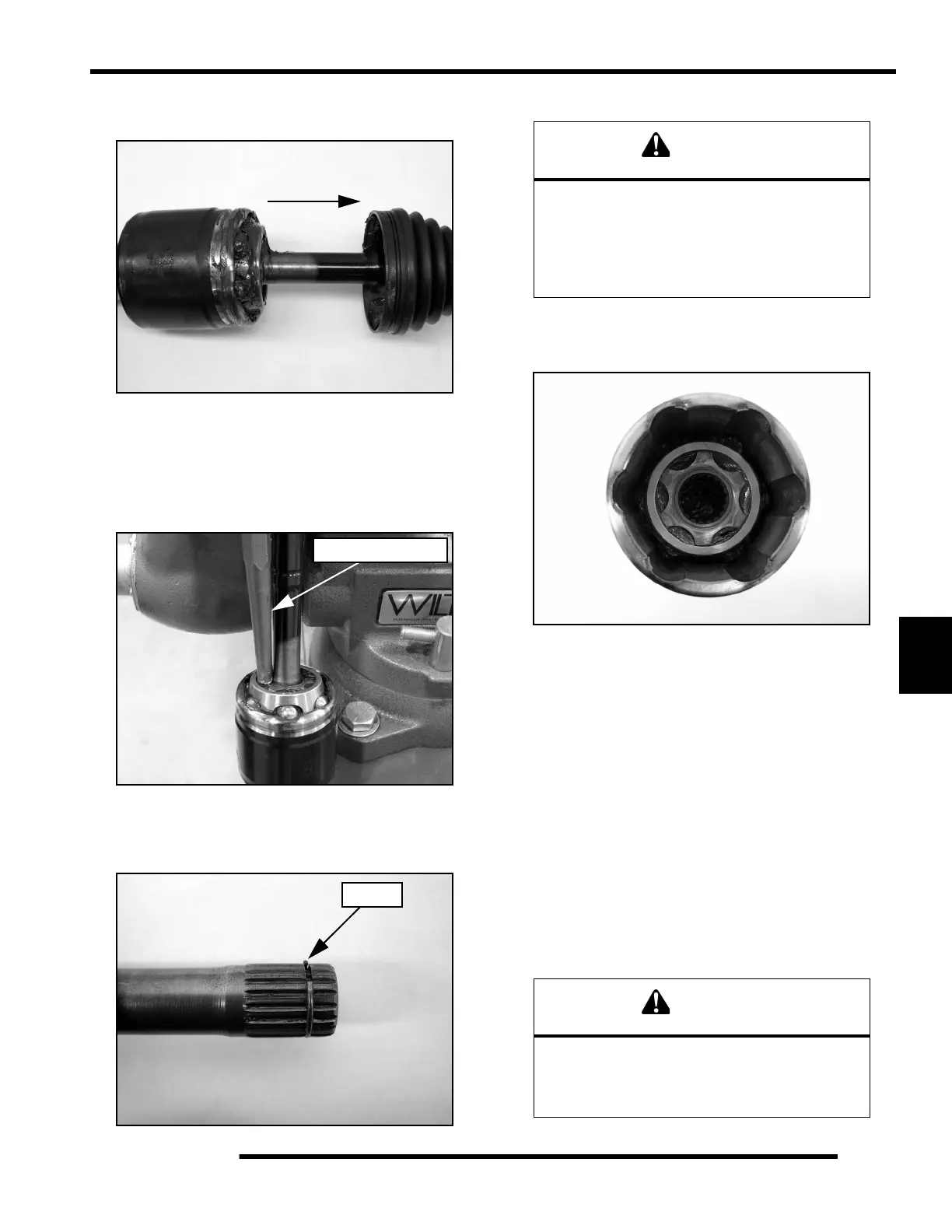

6. Make sure the circlip is still on the shaft and not left in the

joint.

7. Remove the boot from the shaft.

IMPORTANT: If the grease in the joint is obviously

contaminated with water and/or dirt, the joint should

be replaced.

8. Thoroughly clean the joint with an appropriate solvent and

dry the joint to prevent any residual solvent from being left

in the joint upon reassembly.

9. Visually inspect the joint for damage. Replace if needed.

10. Clean the splines on the end of the shaft and apply a light

coat of grease prior to reassembly.

11. Slide the small boot clamp and boot (small end first) onto

the drive shaft and position the boot in its groove machined

in the shaft.

12. Install a NEW circlip on the end of the shaft.

13. Grease the joint with the special joint grease provided in the

boot replacement kit. Fill the cavity behind the balls and the

splined hole in the joint’s inner race. Pack the ball tracks

and outer face flush with grease. Place any remaining

grease into the boot.

Complete disassembly of the plunging joint is

NOT recommended. The internal components

are a precision fit and develop their own

characteristic wear patterns. Intermixing the

internal components could result in looseness,

binding, and/or premature failure of the joint.

The grease provided in the replacement kit is

specially formulated for wear resistance and

durability. DO NOT use substitutes

or mix with other lubricants.

Loading...

Loading...