9.17

BRAKES

9

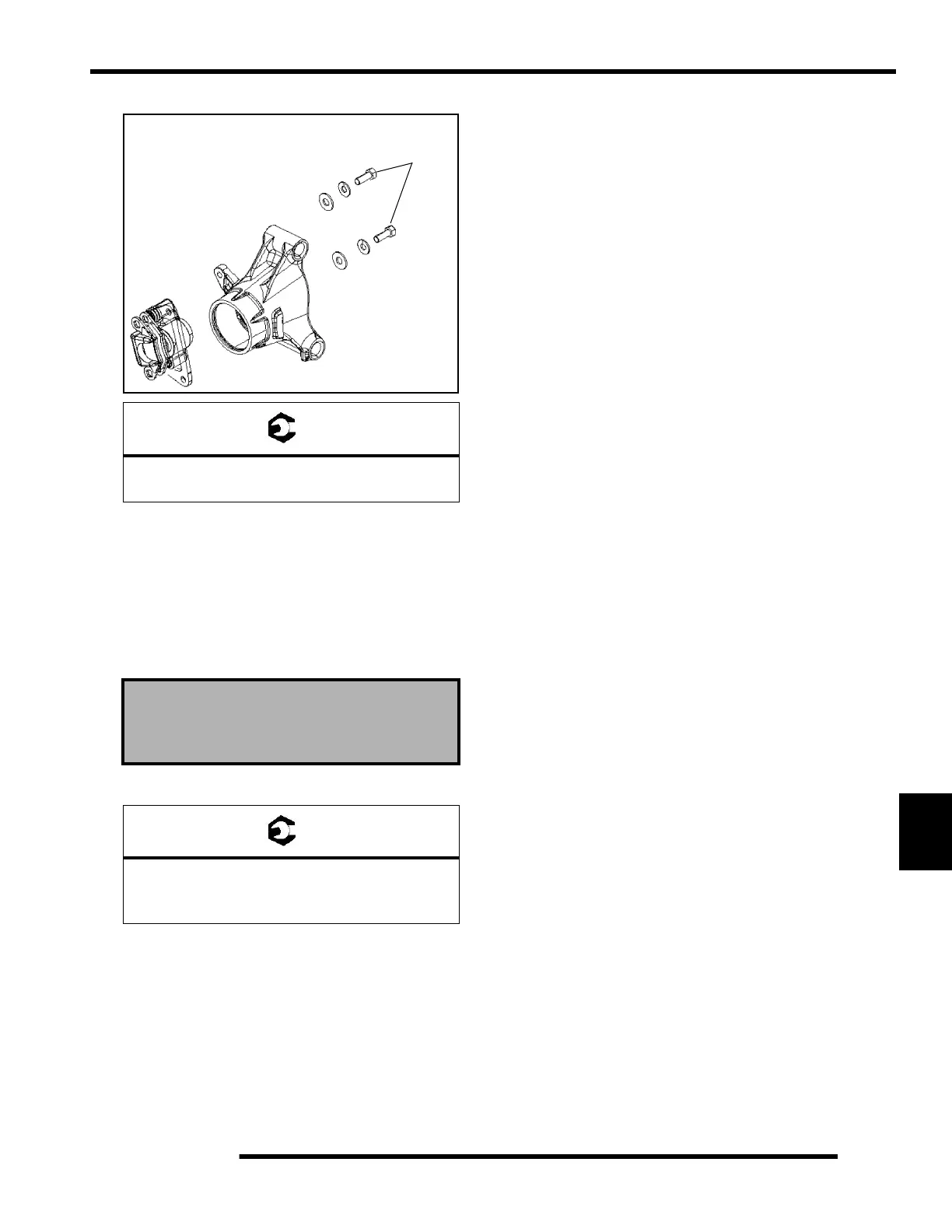

3. Install caliper and torque mounting bolts to specification.

4. Slowly pump the brake pedal until pressure has been built

up. Maintain at least 1/2, (12.7 mm) of brake fluid in the

reservoir to prevent air from entering the brake system.

5. Install the adjustment set screw and turn clockwise until the

stationary pad contacts the disc, then back off 1/2 turn.

6. Verify fluid level in reservoir is up to the MAX line inside

reservoir and install reservoir cap.

7. Install wheel and torque wheel nuts to specification.

Brake Burnishing Procedure

It is required that a burnishing procedure be performed after

installation of new brake pads to extend service life and reduce

noise.

Start machine and slowly increase speed to 30 mph. Gradually

apply brakes to stop machine. Allow pads and disc to cool

sufficiently during the procedure. Do not allow pads or disc to

become hot or warping may result. Repeat this procedure 10

times.

Rear Caliper Mount Bolt Torque:

18 ft. lbs. (24 Nm)

Master Cylinder Fluid

Up to MAX line inside reservoir

Wheel Nuts:

Steel Wheels: 35 ft. lbs. (47 Nm)

Aluminum Wheels: 30 ft. lbs. + 90° (1/4 turn)

Loading...

Loading...