4.34

ELECTRONIC FUEL INJECTION

IGNITION COIL

Operation Overview

The ignition coil is used to provide high voltage to fire the spark

plugs. When the ignition key is on, DC voltage is present in

primary side of the ignition coil windings. During engine

rotation, an AC pulse is created within the crankshaft position

sensor for each passing tooth on the flywheel. The two-tooth gap

creates an “interrupt” input signal, corresponding to specific

crankshaft position. This signal serves as a reference for the

control of ignition timing. The ECU then calculates the time

interval between the consecutive pulses, and determines when

to trigger the voltage spike that induces the voltage from the

primary to the secondary coil windings to fire the spark plugs.

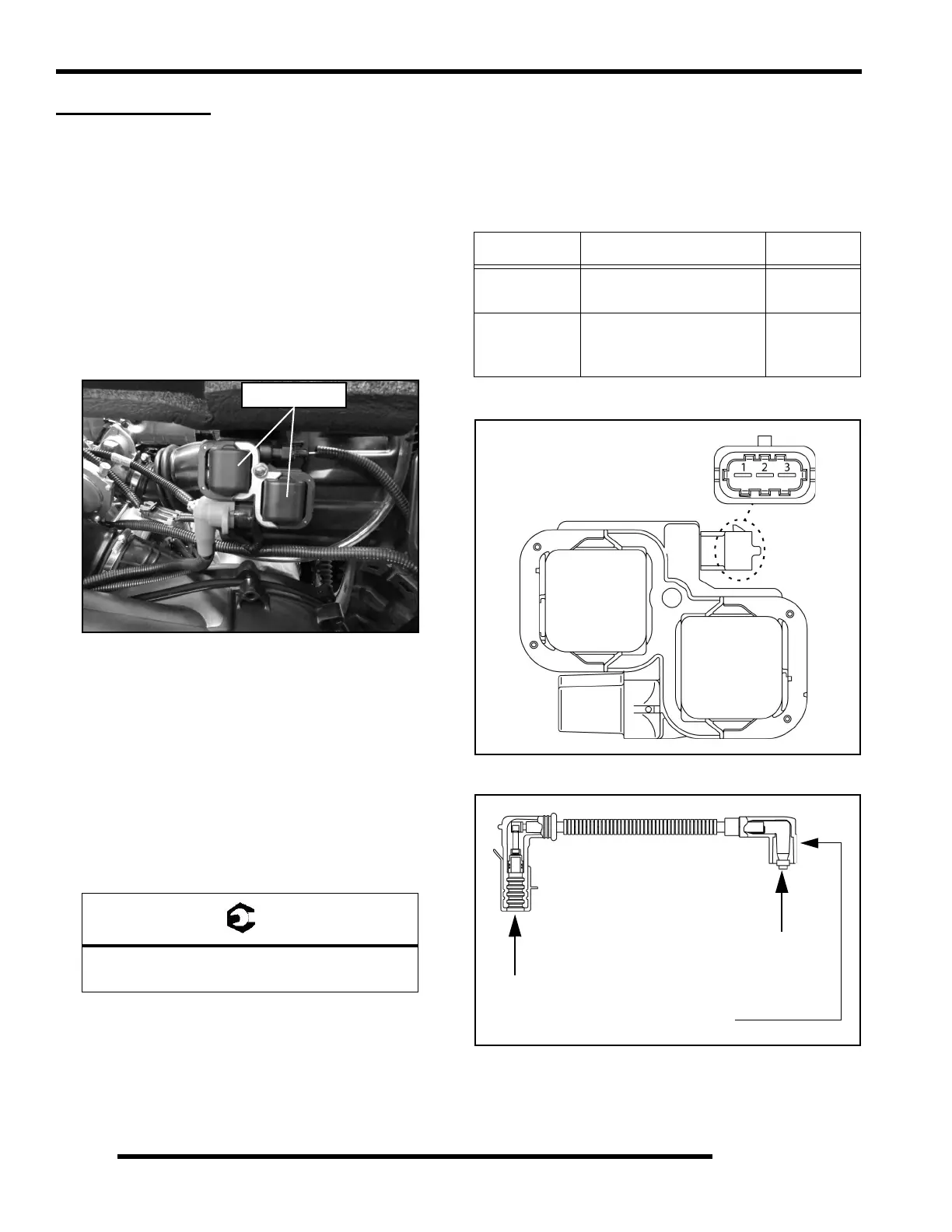

Ignition Coil / HT Lead Replacement

1. Remove the driver and passenger seats.

2. Remove the rear service panel to access the ignition coil.

3. Disconnect the ignition coil harness and remove the high

tension leads from the coil.

4. Remove the fastener retaining the ignition coil and remove

it from the vehicle. If replacing the high tension lead(s),

remove the other end of the lead(s) from the spark plug.

5. Install the new ignition coil and/or high tension lead(s).

NOTE: Be sure to mark / note which ignition coil

wire goes to which cylinder and ignition coil post.

The engine will misfire if the spark plug wires are

installed incorrectly. The spark plug wires are

marked PTO and MAG and should be installed to the

corresponding cylinder spark plug and coil post.

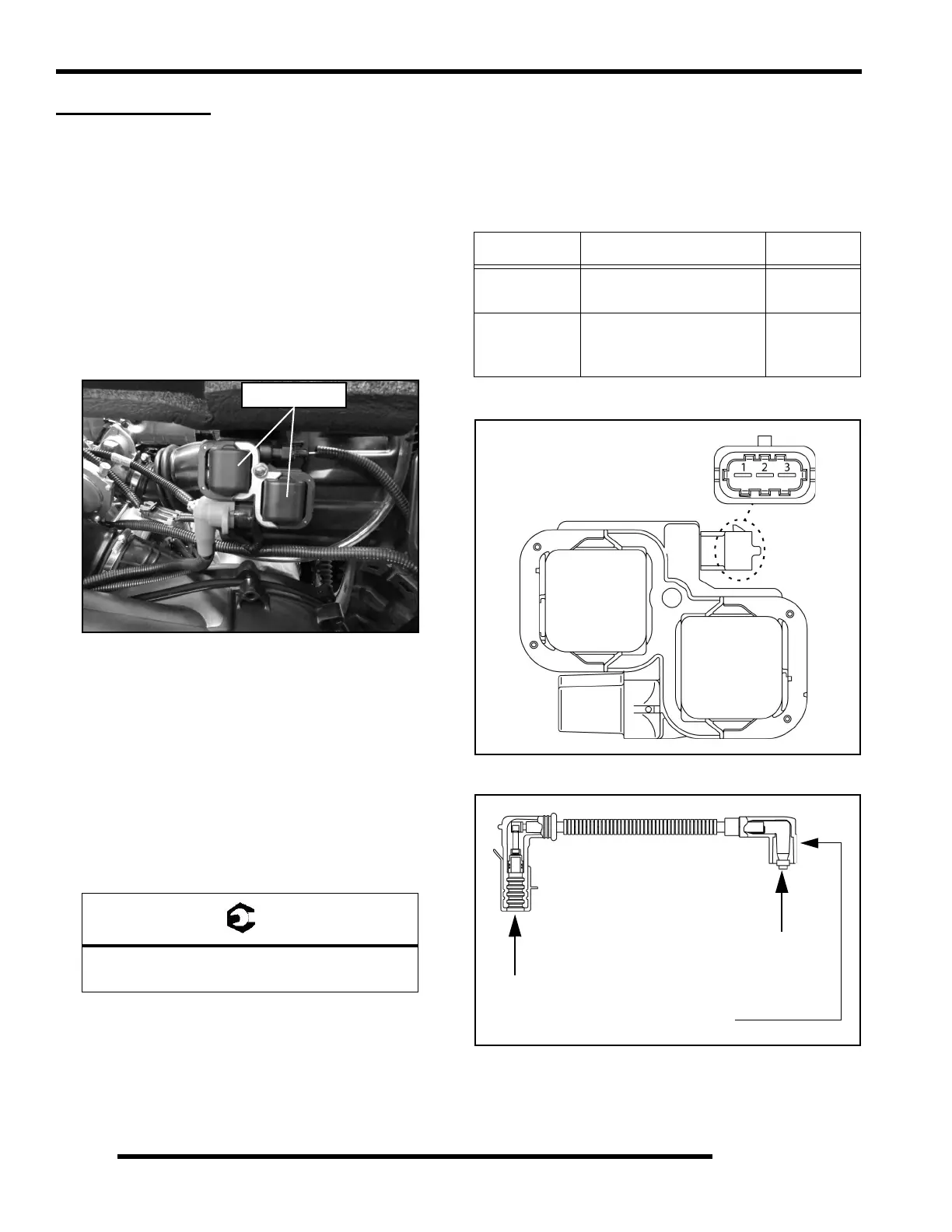

Ignition Coil Tests

The ignition coil can be tested by using an ohm meter. Use the

following illustration and specification table to test the ignition

coil.

Primary Test

Secondary Test

Ignition Coil Retaining Bolt Torque:

75 in. lbs. (8.5 Nm)

Ignition CoilIgnition Coil

Ignition Coil Resistance Readings

Test Pin Connection Resistance

Primary

Between 1 & 2

Between 2 & 3

0.4

Secondary

Between High Tension

Lead End Caps

(Red end caps on coil end)

6.6 k

Measure Between

Connector Pins

0.4

Measure Between End Caps

6.6k

Loading...

Loading...