10.29

ELECTRICAL

10

Voltage Drop Test

The Voltage Drop Test is used to test for bad connections. When

performing the test, you are testing the amount of voltage drop

through the connection. A poor or corroded connection will

appear as a high voltage reading. Voltage shown on the meter

when testing connections should not exceed .1 VDC per

connection or component.

To perform the test, place the meter on DC volts and place the

meter leads across the connection to be tested. Refer to the

voltage drop tests on the starter system in this chapter.

Starter Motor Removal / Disassembly

NOTE: Use electrical contact cleaner to clean starter

motor parts. Some solvents may leave a residue or

damage internal parts and insulation.

1. Remove the starter from the engine.

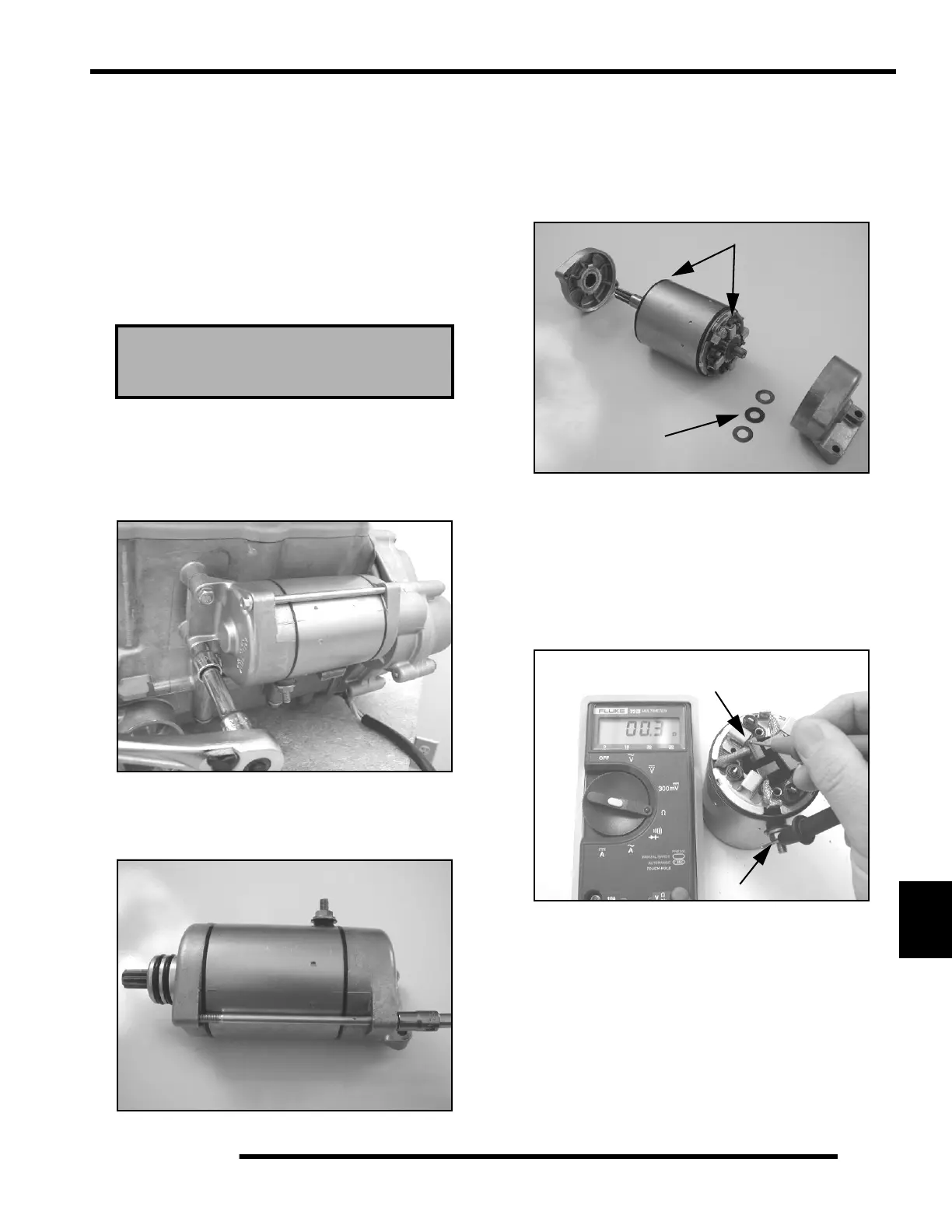

2. Remove the two bolts, washers, and sealing O-Rings.

Inspect O-Rings and replace if damaged.

NOTE: Note the alignment marks on both ends of

the starter motor casing. These marks must align

during reassembly.

3. Remove the front bracket assembly and the rear bracket

assembly. Remove the shims from the armature shaft and

inspect the O-rings located on the armature housing.

NOTE: The shims will be replaced during

reassembly.

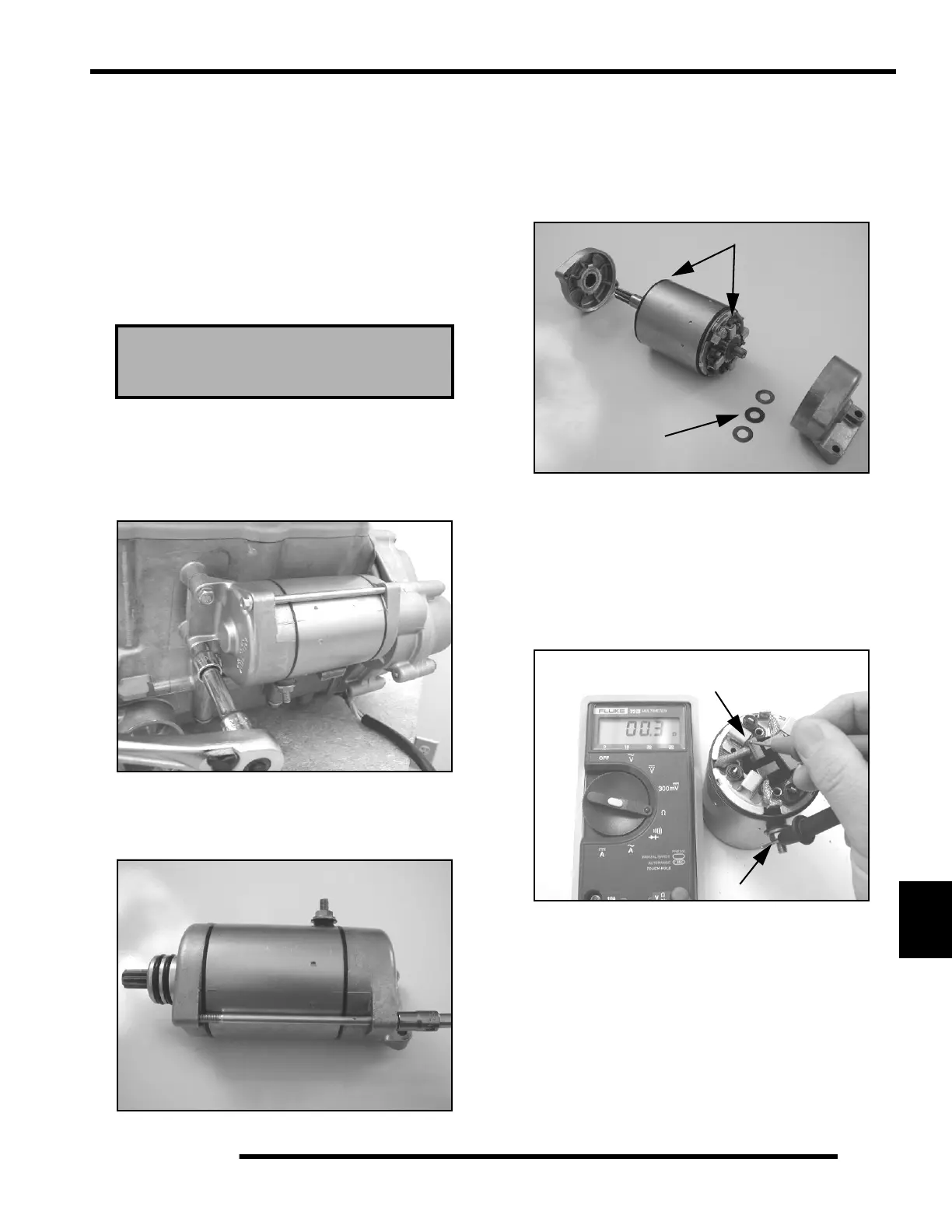

Brush Inspection / Replacement

1. Measure resistance between starter input terminal and

insulated brushes. The reading should be .3 ohms or less.

Remember to subtract meter lead resistance.

Voltage should not exceed

.1 DC volts per connection

Loading...

Loading...