7.32

FINAL DRIVE

NOTE: The amount of grease that’s provided is pre-

measured, so use all the grease.

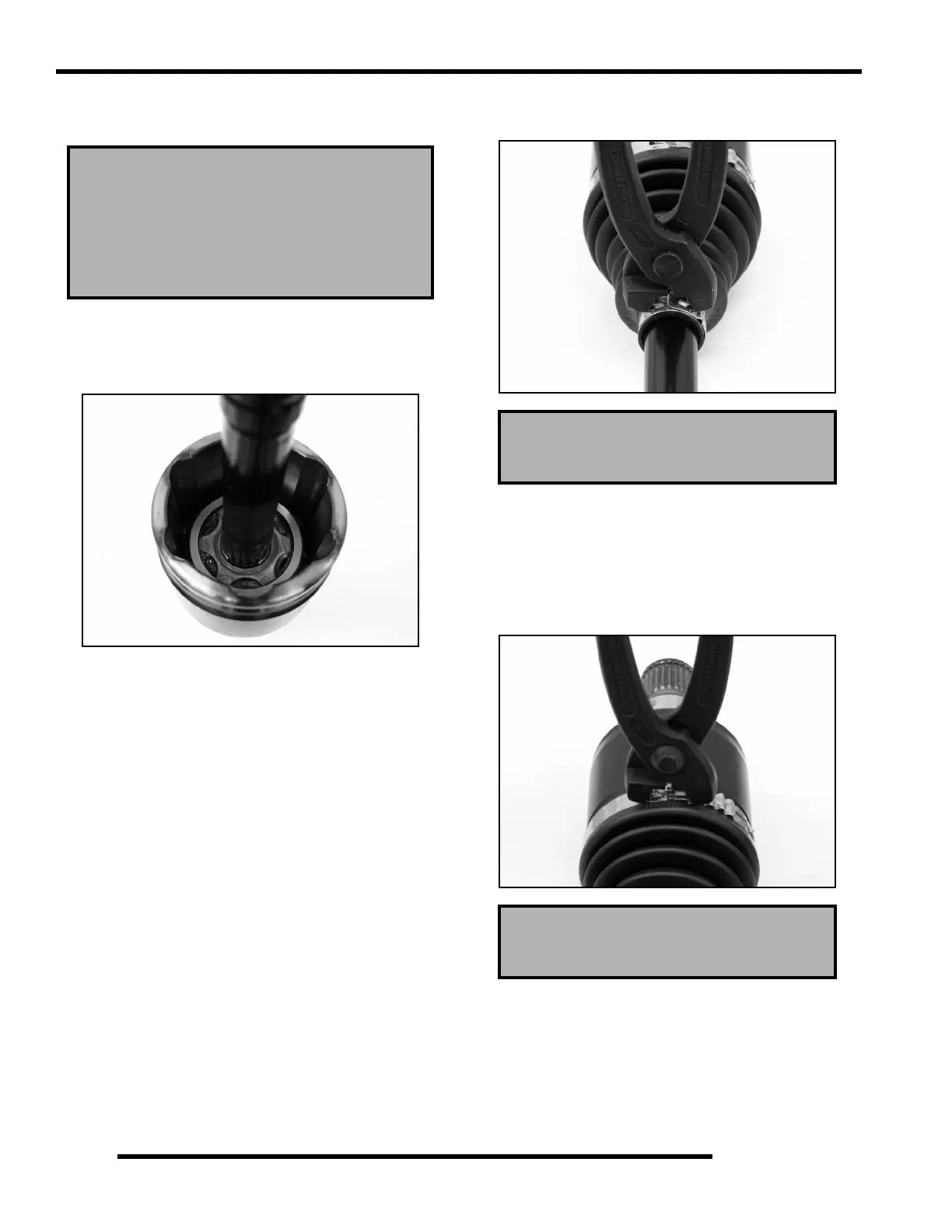

14. Fully compress the joint and push the drive shaft firmly into

the inner race.

15. Align the circlip with the lead-in chamfer.

16. Use a soft-faced hammer to tap the joint onto the drive shaft

until you reach the end of the splines and the joint locks in

place.

17. Pull on the joint to test that the circlip is seated and that the

joint is securely fastened to the shaft.

18. Remove excess grease from the plunging joint’s external

surfaces and place the excess grease in the boot.

19. Pull the boot over the joint and position the boot lips into

the grooves on the joint housing and shaft. Make sure the

boot is not dimpled or collapsed.

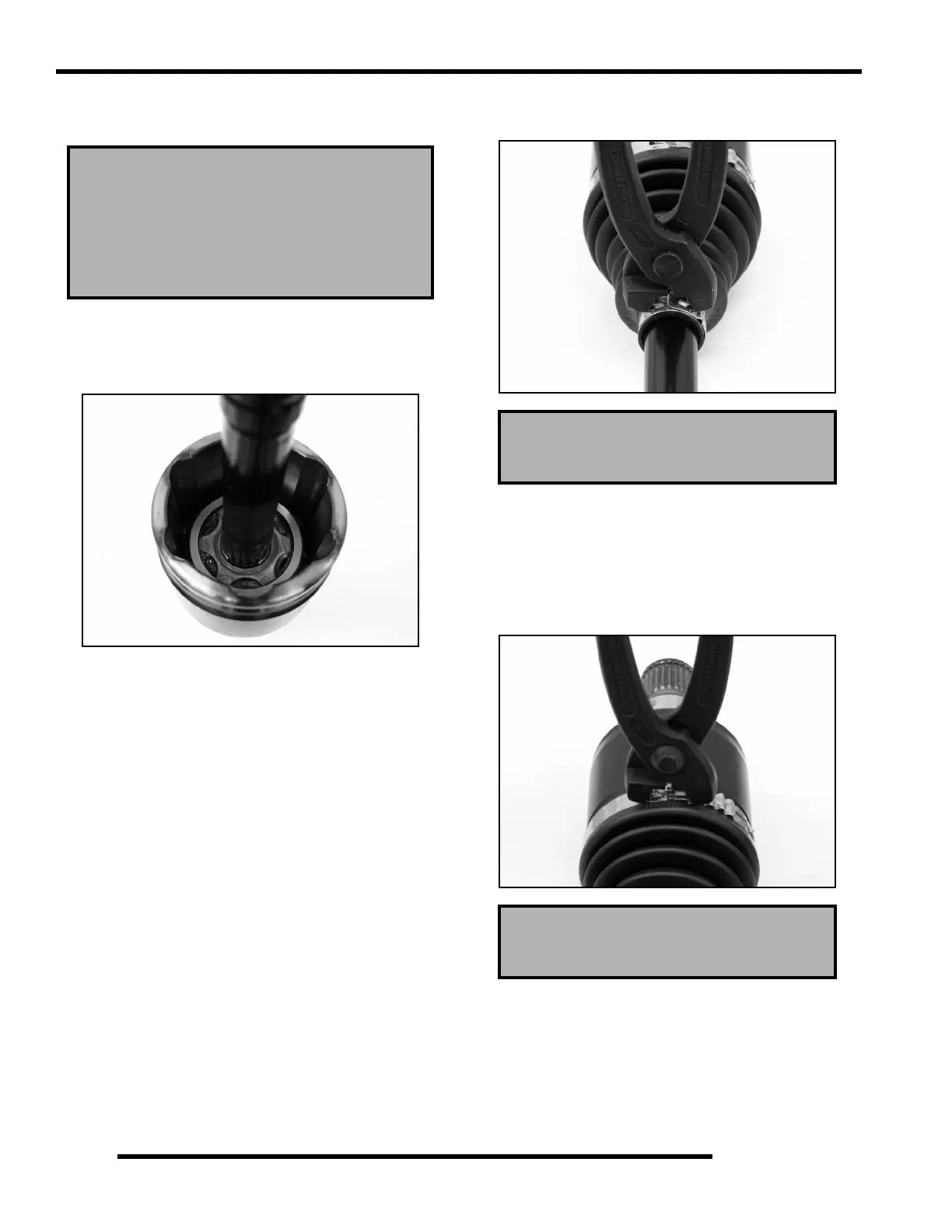

20. Install and tighten the small clamp using the Axle Boot

Clamp Tool (PU-48951).

21. Pull out on the drive shaft to center the joint in the housing.

Slide a straight O-ring pick or a small slotted screw driver

between the large end of the boot and the joint housing and

lift up to equalize the air pressure in the boot.

22. Position the boot lip in its groove. Install and tighten the

large clamp using the Axle Boot Clamp Tool (PU-48951).

Boot Replacement Grease Requirement:

Grease Only Service Kits

PN 1350059 (20g) / PN 1350046 (30g) / PN 1350047 (50g)

Inner Plunging Joint Capacity: 90g

Axle Boot Clamp Tool

PU-48951

Axle Boot Clamp Tool

PU-48951

Loading...

Loading...