4000-SERIES INSTALLATION, OPERATION AND SERVICE MANUAL

124 of 154

adjustment.

Table 35: Motor Sheave Drive Torque

Specifications

Table 36: Motor and Blower Bushing Torque

Specifications

21.4.2 Burner Pressure

1. A pressure tap is used to measure differential

at the burner and to set high fire gas pressure.

The pressure tap could be located on the

downstream side of the MR212 valve, on a T-

fitting coming off the outlet pressure tap on the

MR212 valve or between the MR212 valve and

the burner. See Page 71 through Page 73, Fig-

ures 55 - Figure 57 and Page 127, Figure 77.

2. Measure the burner pressure with the inlet

manual gas valve off.

- Open the manual shut off located between

the modulating valve and the burner.

- T

urn the blower on and record the negative

pressure on a u-tube manometer or gas

pressure gauge. This reading is used for high

fire burner pressure adjustment.

3. After taking the burner pressure reading, tem-

porarily leave the manometer attached to the

1/8" tap. It will be used later to check high fire

gas pressure.

21.5 Gas Piping and Initial Pressure Settings

1. Perform a pressure test on all gas supply lines

to the air handler per applicable codes.

Make sure to isolate all gas controls before

pressure testing the system.

2. Verify supply pressure does not exceed maxi-

mum rated gas pressure as stated on the rating

plate.

3. Set the supply gas pressure at the step down

regulator (normally outside of the enclosure if

one is installed) according to the nameplate

rating inlet gas pressure specifications.

4. Only after performing steps 1-3 (above), verify

pilot pressure.

•Place a u-tube manometer or gas pressure

gau ge on the tee at the downstream side of

the pilot pressure regulator.

• Open the main gas valve and close the gas

valve downstream of the MR valve.

•Set the burner switch to "on" and adjust the

pilot pressure regulator to 1.0 in wc for

natural gas or 0.5 in wc for LPG.

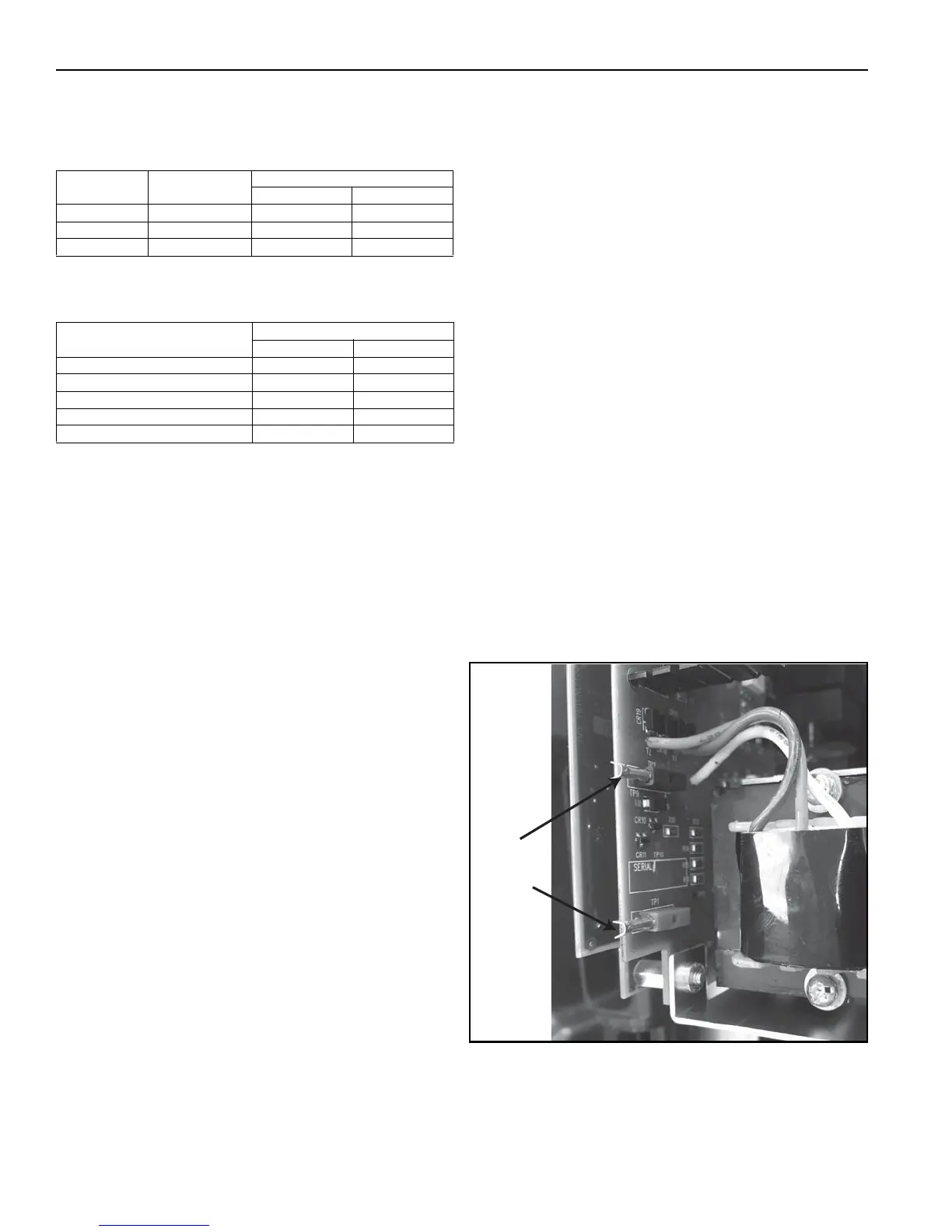

• Verify that the burner flame control has a

flame signal of 6-8 Vdc.

See Page 124,

Figure 76

.

FIGURE 76: Fireye Flame Module

Setscrew Size Allen Wrench

Torque Settings

in

•Lbs ft•Lbs

1/4" 1/8" 87 7.3

5/16" 5/32" 120 10.0

3/8" 3/16" 290 24.2

Bolt Size (on Bushing)

Torque Settings

in

•Lbs ft•Lbs

#10 60 5

1/4" 108 9

5/16" 192 16

3/8" 360 30

1/2" 720 60

Loading...

Loading...