SECTION 24: TROUBLESHOOTING

137 of 154

24.1 Initial Checks

When encountering any abnormal operation or fault conditions of the equipment, all troubleshooting should

start with the following initial checks. If a problem is discovered in these initial checks it must be corrected

before moving on in the trouble shooting.

1. Compare voltage and phase of supply power on site with rating plate information.

2. Review wiring between remote panel and control panel. Do the electrical connections match the sup-

plied wiring diagram?

3. Compare gas type and supply pressure on site with rating plate information.

4. Check for proper blower rotation on air handler and any exhaust blowers.

•Blowers powered with a three phase motor can be reversed by swapping any two incoming power

legs. For blowers powered by a single phase motor refer to the motor rating plate for reversing

instructions.

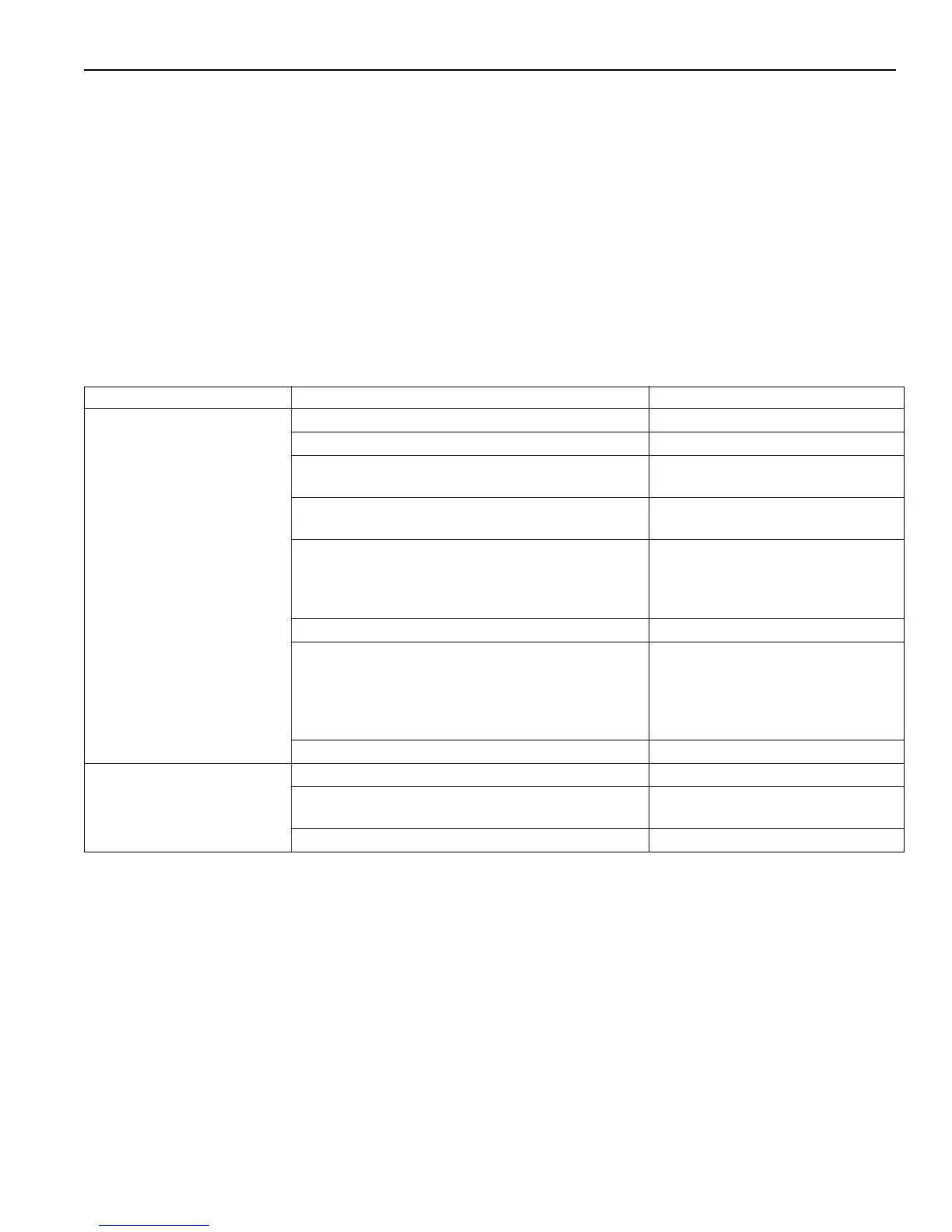

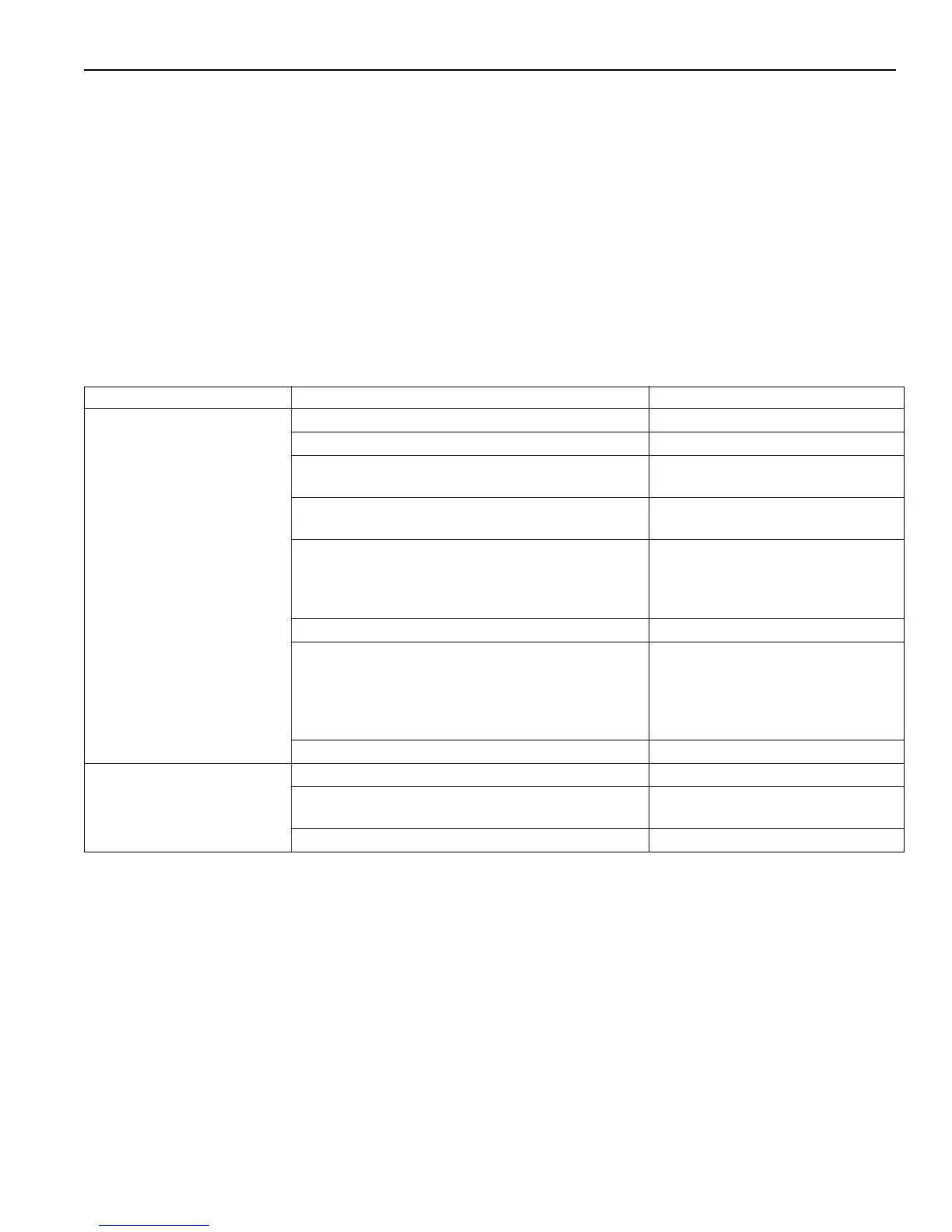

24.2 Motor and Blower

PROBLEM POSSIBLE CAUSE SOLUTION

Motor does not operate Main disconnect switch is OFF Turn disconnect to ON

Blown fuse(s) in disconnect Replace fuse(s)

Blown fuse(s)/breaker tripped in control transformer Replace fuse(s)/reset breaker (with

disconnect off)

Fan switch on Check wiring between remote panel

and air handler. Replace switch.

Optional: Damper does not open Check that damper is not obstructed

Check that linkage is tight and

secure

Replace damper actuator

Motor starter (contactor) does not operate. Replace starter

Tripped motor overload. Power out to MUA motor

when motor starter is energized?

Reset

Check for proper FLA setting

Replace overload

If applicable: Tighten screws on

heater packs or overload.

Optional: Low limit switch set to high Re-adjust low limit switch setting

Blower does not operate Belts broken or loose? Replace/tighten belts

Loose motor or blower sheaves (pulleys) Reinstall and properly torque set-

screws

Blower bearings, do they turn freely? Replace bearing(s)

Loading...

Loading...