Rockwell Automation Publication 2080-UM002M-EN-E - April 2022 229

Chapter 11 Using microSD Cards

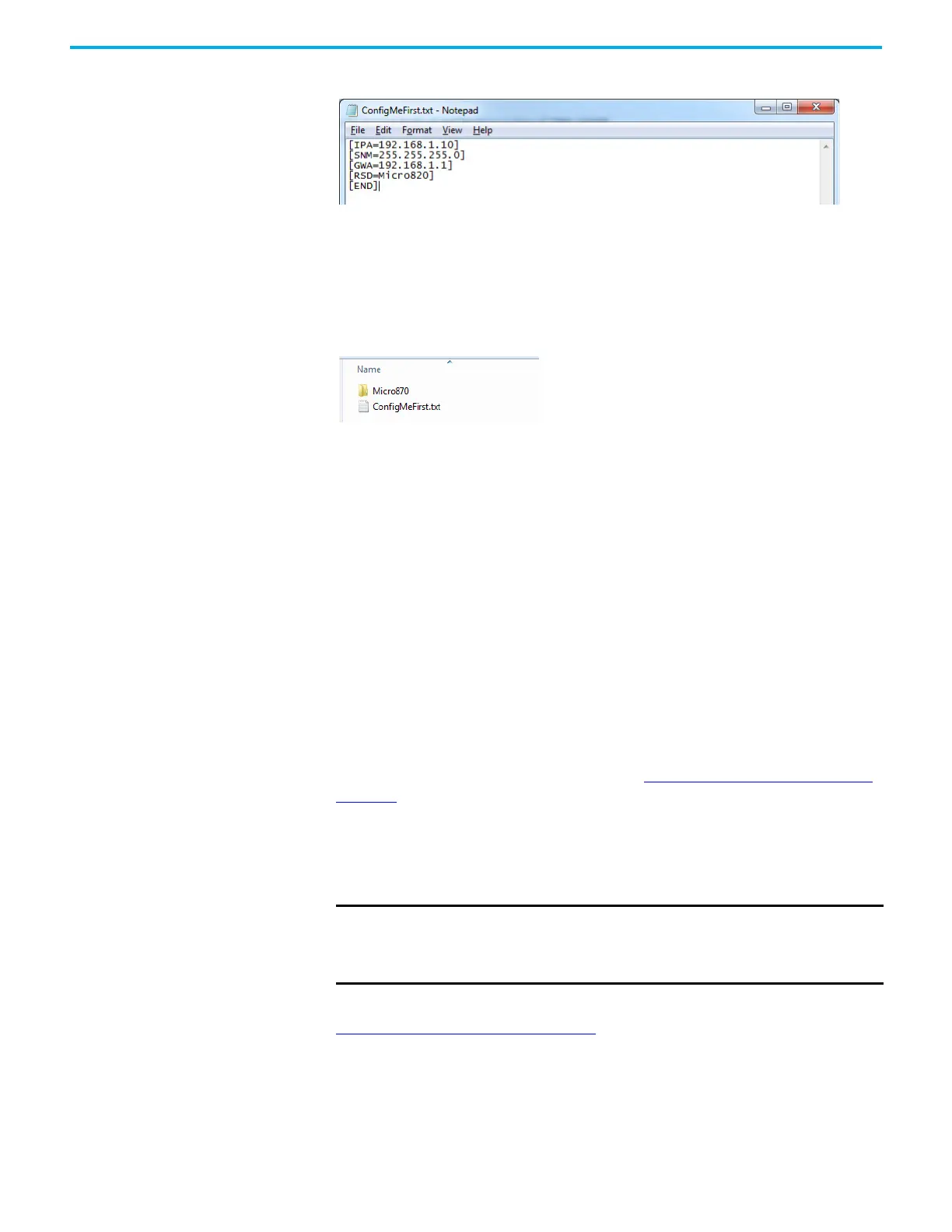

Figure 20 - Example Configuration for Project Restore

In the example shown above, the ConfigMeFirst.txt file configures the IP

address, subnet mask, and gateway of the controller, and restores the project

from the location specified on the microSD card.

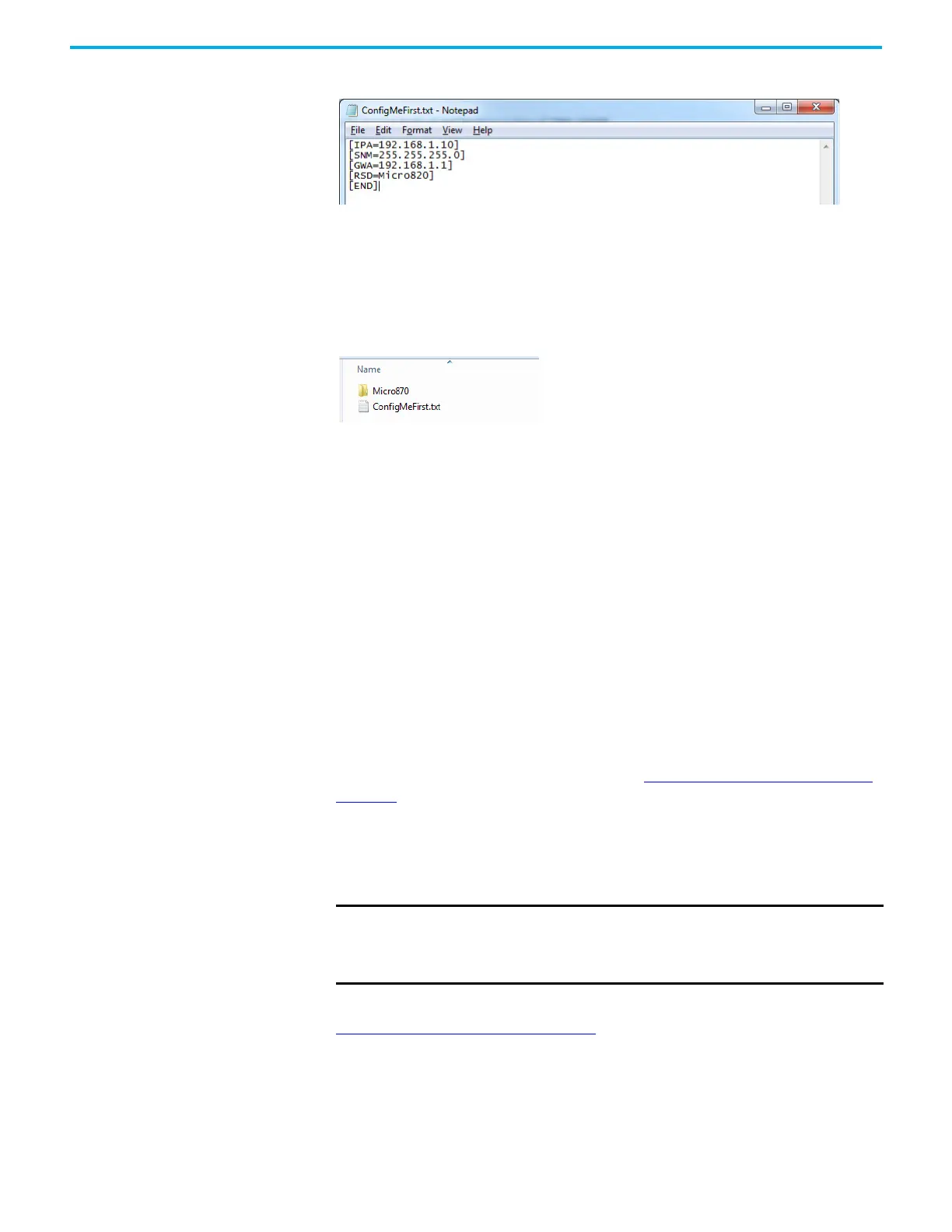

The ConfigMeFirst.txt file must be placed in the same root directory as the

backup folder in the microSD card.

1. Insert the microSD card into the microSD card slot.

2. Cycle power to the controller.

3. When the SD LED displays a steady green light, the project restore is

complete.

Data Log The data logging feature allows you to capture global and local variables with

timestamp from the Micro800 controller into the microSD card. You can

retrieve the recorded datasets on the microSD card by reading the contents of

the microSD card through a card reader or by doing an upload through the

Connected Components Workbench software.

A maximum number of 10 datasets is supported for a Micro800 program. Each

dataset can contain up to 128 variables, with a maximum of four data string

variables per dataset. String variables can have a maximum of 252 characters.

All datasets are written to the same file. For more information on how data

logs are stored on the microSD card, see the Data Log Directory Structure

on

page 230.

You can retrieve data log files from the microSD card using a card reader or by

uploading the data logs through the Connected Components Workbench

software.

See the sample quickstart project to get you started on the Data Log feature,

Use the Data Log Feature

on page 239.

IMPORTANT

Uploading data log files in PROGRAM mode is recommended for optimum

performance and to prevent file access conflict. For example, if the data

log instruction is executing, Connected Components Workbench

software will not upload the last data log file.

Loading...

Loading...