280 Rockwell Automation Publication 2080-UM002M-EN-E - April 2022

Appendix B Quickstarts

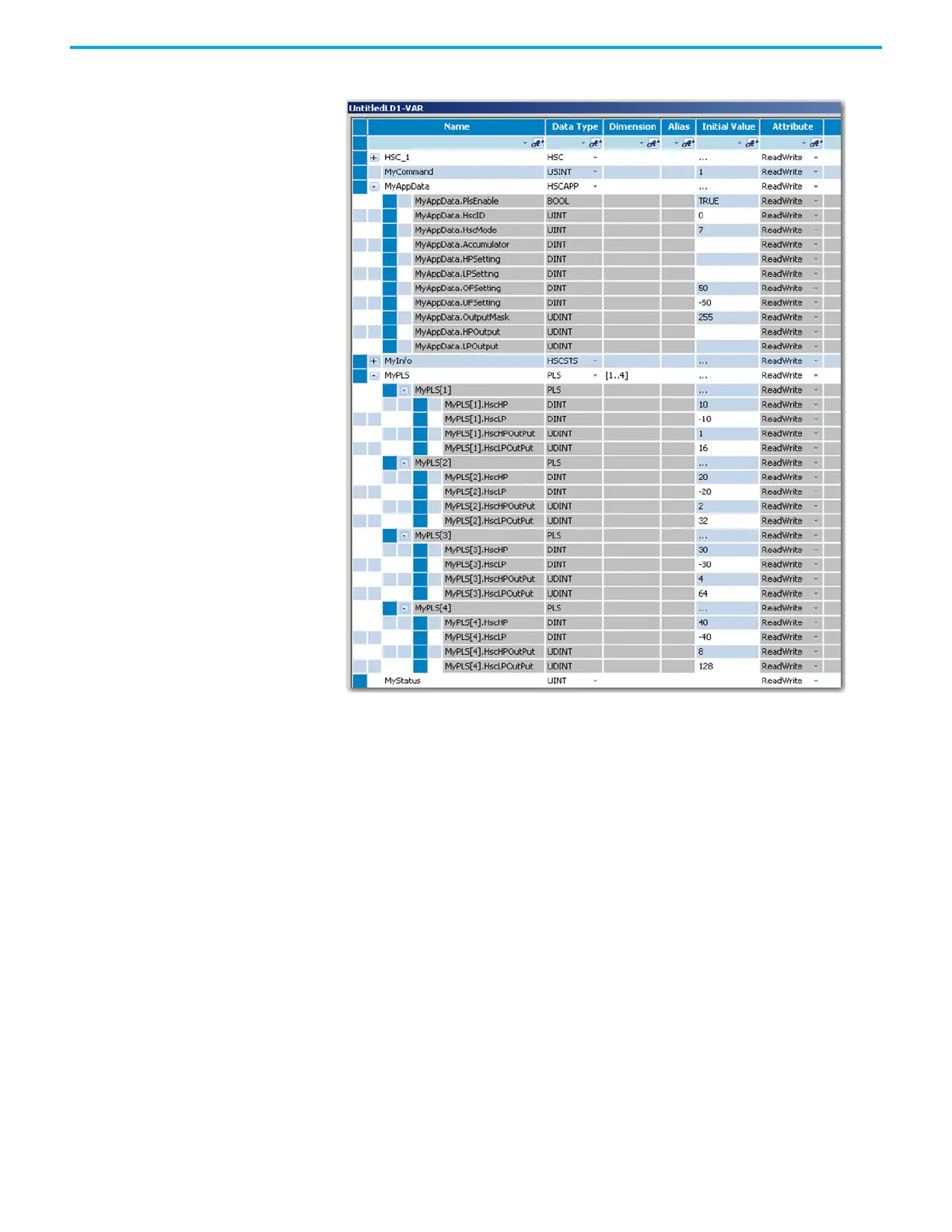

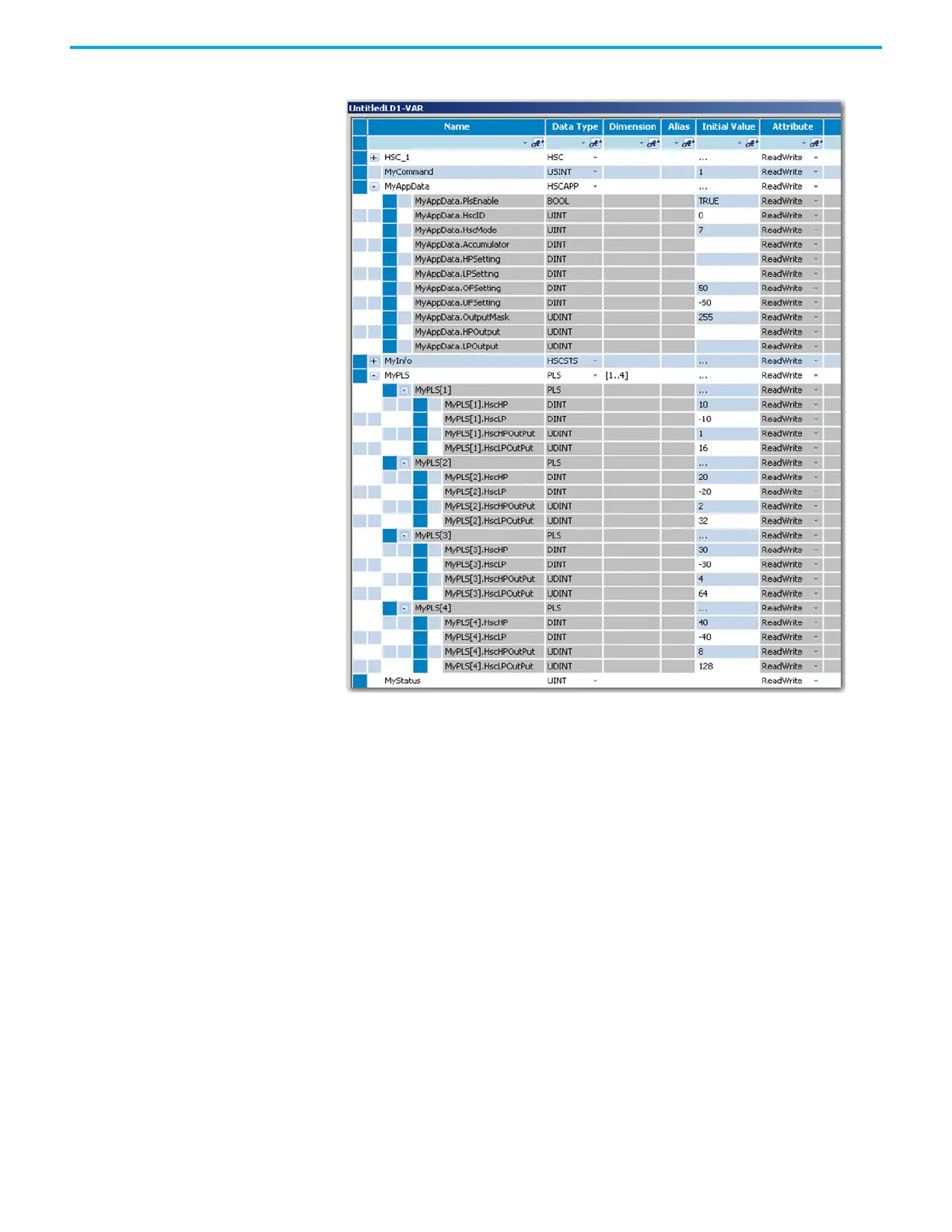

Figure 27 - PLS Values

In this example, the PLS variable is given a dimension of [1..4]. This

means that the HSC can have four pairs of High and Low Presets.

Once again, your High Presets should be set lower than the OFSetting

and the Low Preset should be greater than the UFSetting. The

HscHPOutPut and HscLPOutPut values will determine which outputs

will be turned on when a High Preset or Low Preset is reached.

2. You can now build and download the program into the controller then

debug and test it following the instructions for the last project.

Forcing I/Os Inputs are logically forced. Status indicators do not show forced values, but the

inputs in the user program are forced.

Forcing is only possible with I/O and does not apply to user-defined variables

and non-I/O variables, and special functions such as HSC and Motion that

execute independently from the User Program scan. For example, for motion,

Drive Ready input cannot be forced.

Unlike inputs, outputs are physically forced. Status indicators do show forced

values and the user program does not use forced values.

Loading...

Loading...