170 Rockwell Automation Publication 2080-UM002M-EN-E - April 2022

Chapter 8 Motion Control

Axis Start/Stop Velocity

Start/Stop velocity is the initial velocity when an axis starts to move, and the

last velocity before the axis stops moving. Generally, Start/Stop velocity is

configured at some low value, so that it is smaller than most velocity used in

the motion function block.

• When the target velocity is smaller than Start/Stop velocity, move the

axis immediately at the target velocity.

• When the target velocity is NOT smaller than Start/Stop velocity, move

the axis immediately at Start/Stop velocity.

Real Data Resolution

Certain data elements and axis properties use REAL data format (single-

precision floating point format). Real data has seven-digit resolution and digit

values entered by the user that are longer than seven digits are converted. See

the examples in Table 21

.

If the number of digits is greater than seven (7) and the eighth digit is greater

than or equal to 5, then the seventh digit is rounded up. For example:

21474185 rounded to 2.147419E+07

21474186 rounded to 2.147419E+07

If the eighth digit is <5, no rounding is done and the seventh digit remains the

same. For example:

21474181 rounded to 2.147418E+07

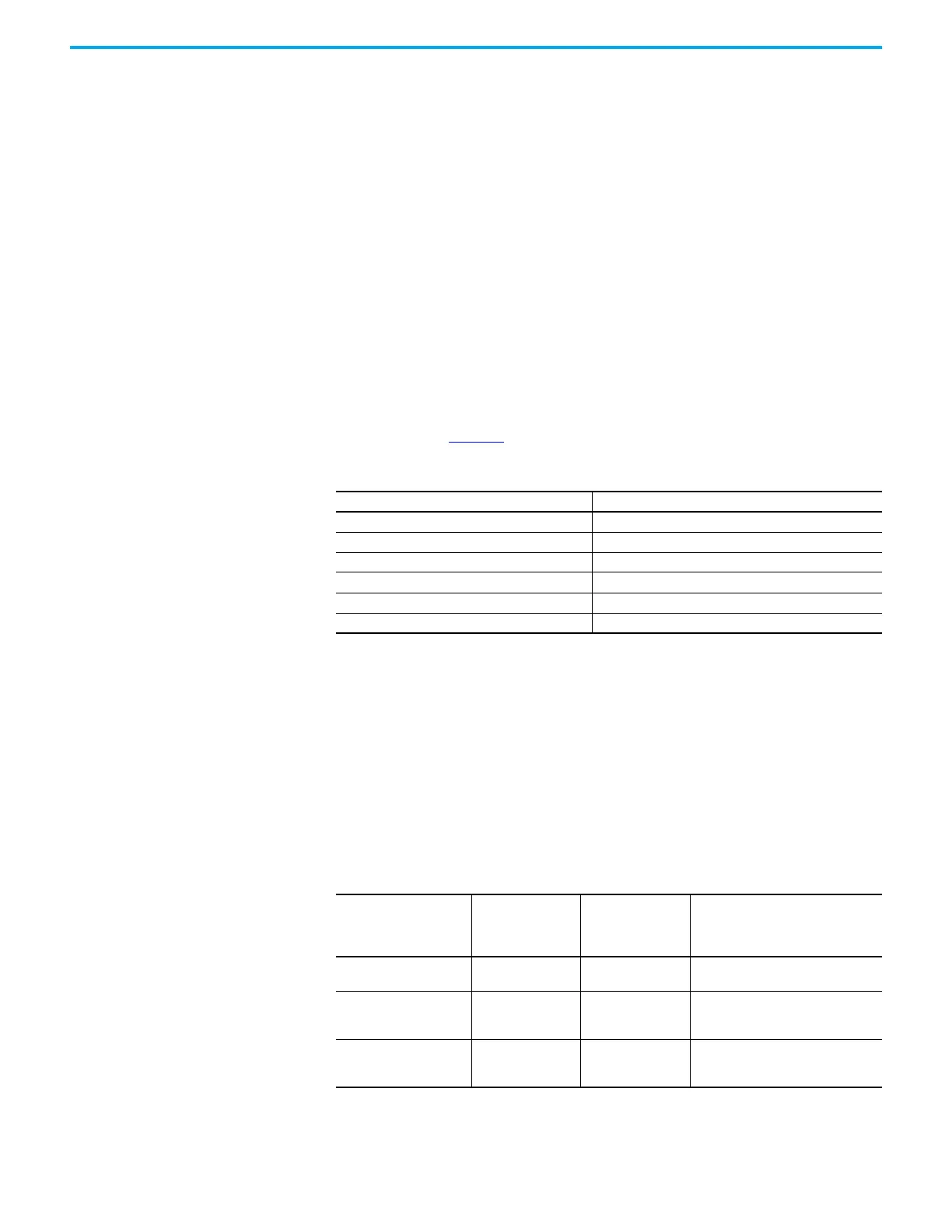

Table 21 - REAL Data Conversion Examples

User Value Converted To

0.12345678 0.1234568

1234.1234567 1234.123

12345678 1.234568E+07 (exponential format)

0.000012345678 1.234568E-05 (exponential format)

2147418166 2.147418+E09

-0.12345678 -0.1234568

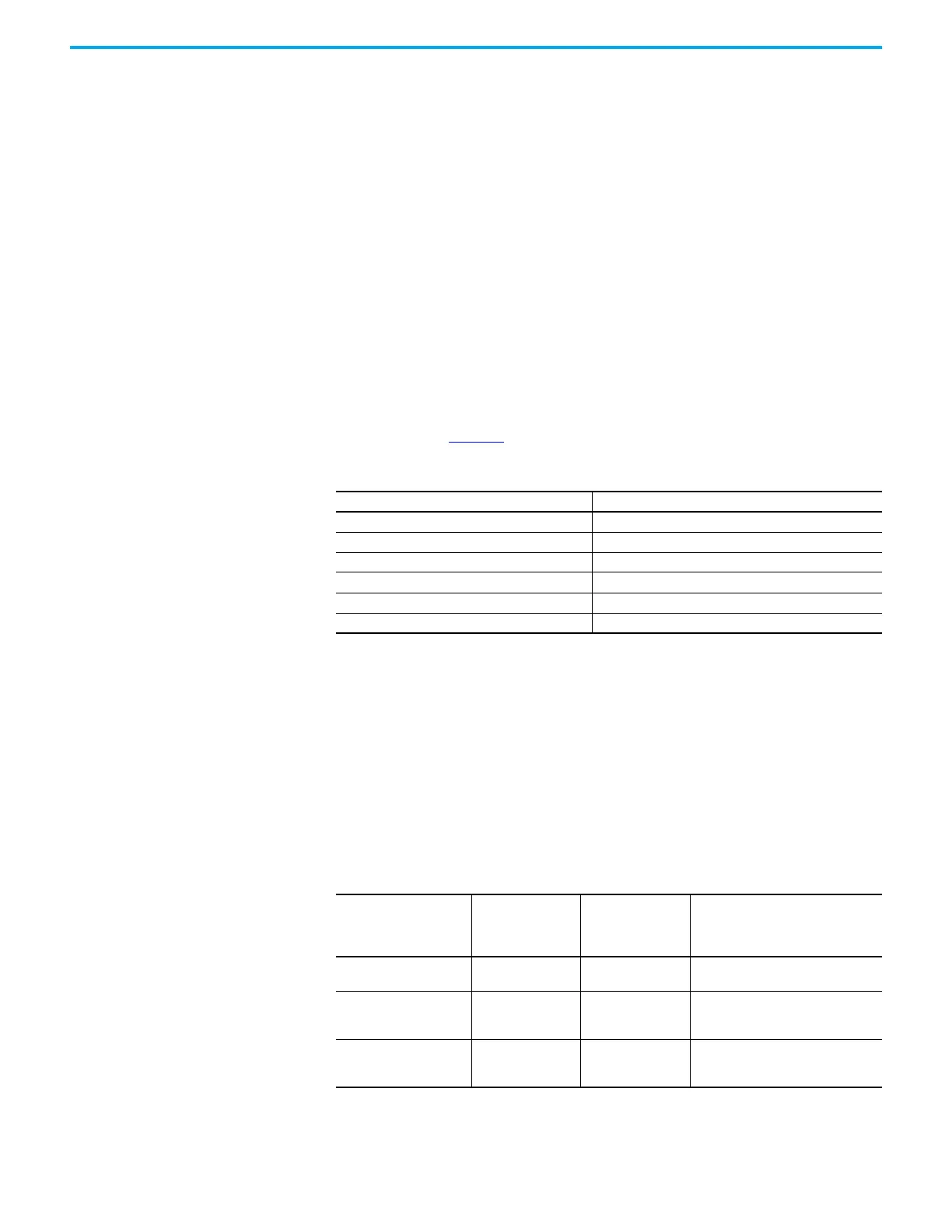

Table 22 - Examples for Motion Configuration

Parameter

Actual Value

Entered by User

Converted Value in

Connected

Components

Workbench

Tooltip Error Value

(1)

(1) On the axis configuration page in Connected Components Workbench, an input field with a red border indicates that the value

that has been entered is invalid. A tooltip message should let you know the expected range of values for the parameter. The

range of values presented in the tooltip messages are also presented in REAL data format.

Pulses per revolution 8388608

8388608

(no conversion)

Pulse per revolution must be in the

range of 0.0001…8388607 user unit.

Upper Soft Limit 10730175 1.073018E+7

Upper Soft limit must be greater than

Lower Soft Limit. The range is from 0

(exclusive) to 1.073217E+07 user unit.

Lower Soft Limit -10730175 -1.073018E+7

Lower Soft limit must be smaller than

Upper Soft Limit. The range is from -

1.073217E+07...0 (exclusive) user unit.

Loading...

Loading...