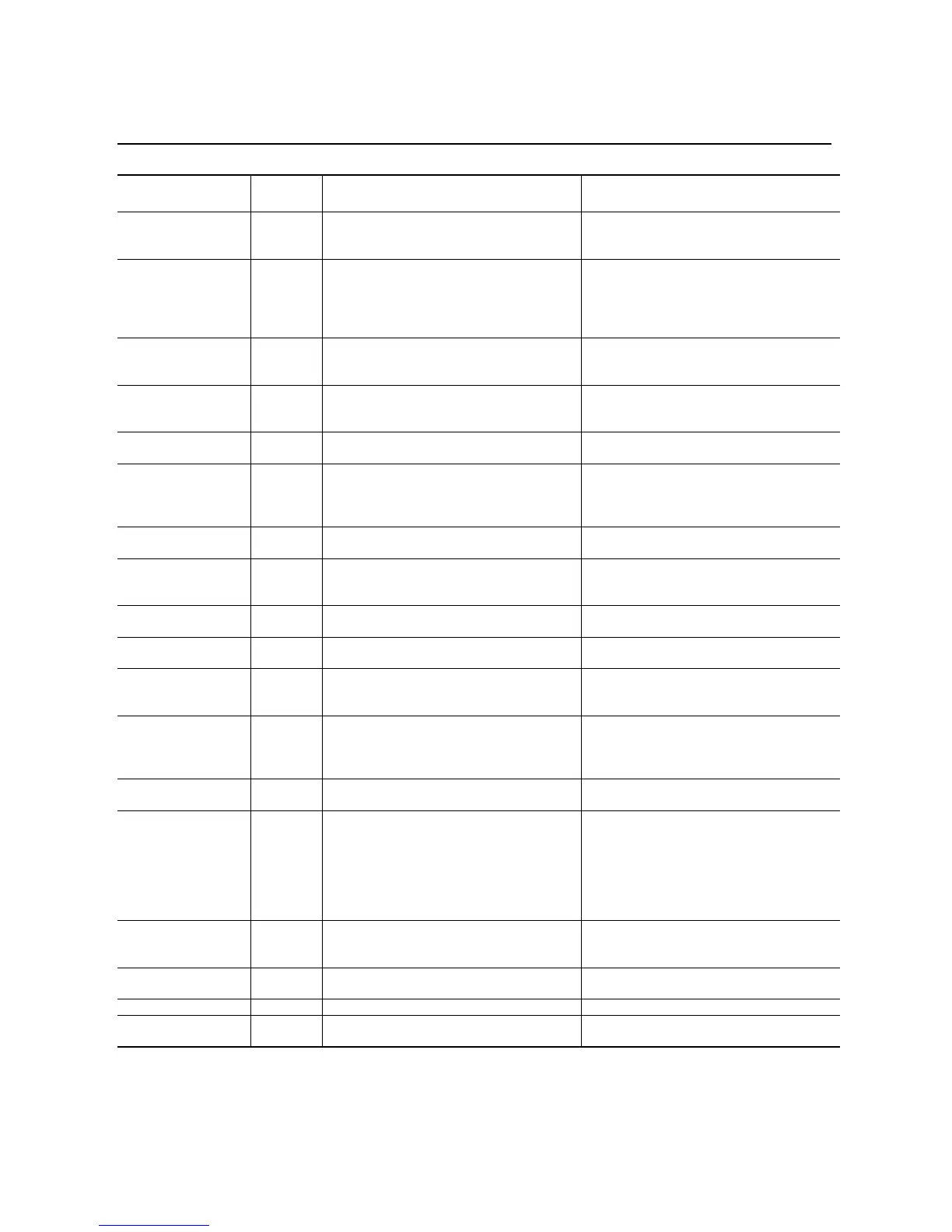

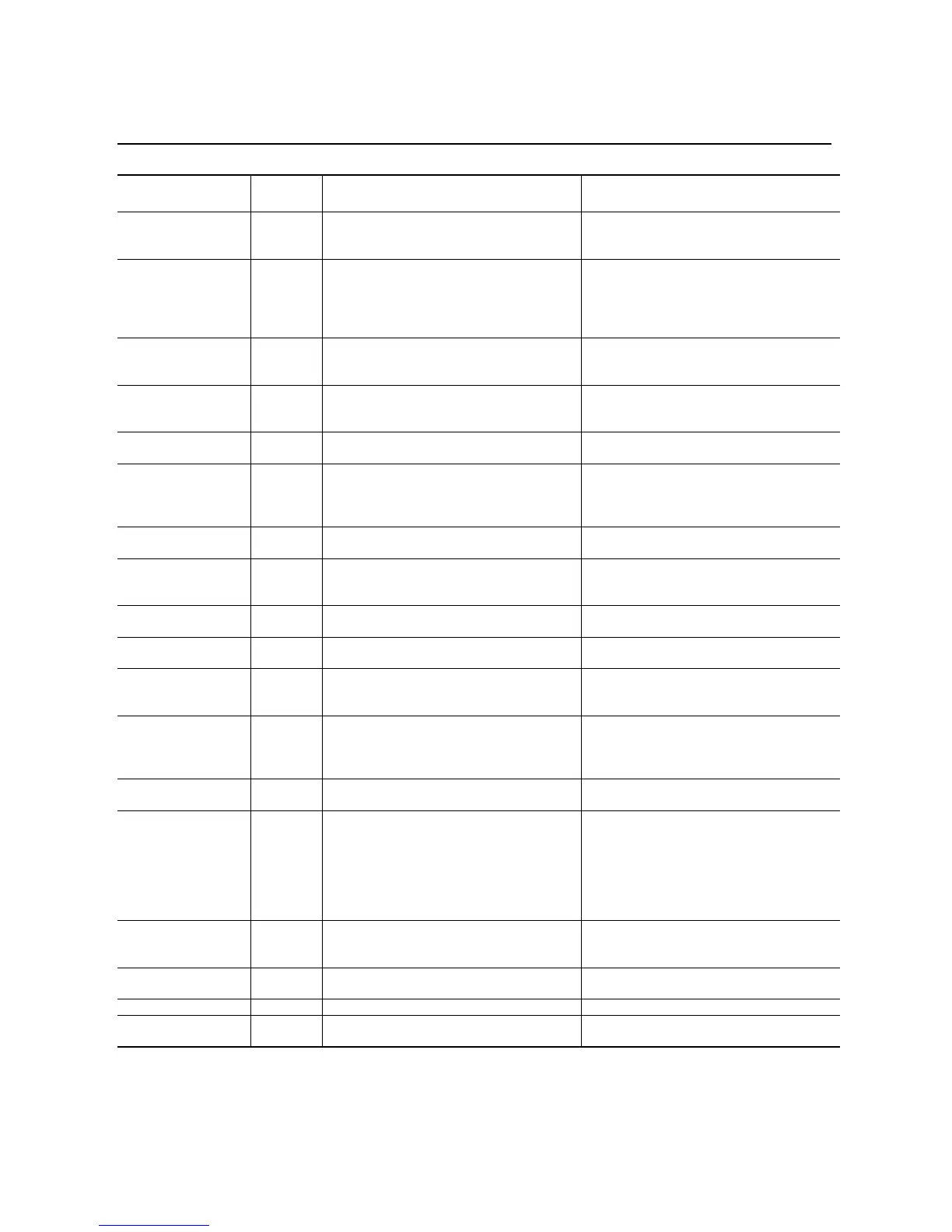

Troubleshooting

10-3

Table 10.A SMC Fault Display Explanation

①

Prestart fault indication.

②

To further define this fault, the user can clear the fault and re-initiate a start signal. If the fault condition is still present, the controller will display either a Power Loss

or a Line Fault with the phase indicated.

Display

Fault

Code

Possible Causes Possible Solutions

Power Loss

①

(with phase indication)

F1, F2, F3,

F30, F31,

& F32

• Missing supply phase (as indicated)

• Converter module and/or cable failure

• Check for open line (i.e., blown line fuse)

• Inspect converter module cable connections

Line Fault

①

(with phase indication)

F11, F12,

F13, F26,

F27, & F28

• Missing supply phase

• Motor not connected properly

•Shorted SCR

• Converter module and/or cable failure

• Check for open line (i.e., blown fuse)

• Check for open load lead

• Check for shorted SCR; replace if necessary

• Inspect converter module cable connections

• Consult the factory

Line Fault

②

(no phase indication)

F15 and

F29

• Missing supply phase

• Motor not connected properly

•Shorted SCR

• Check for open line ( i.e., blown fuse)

• Check for open load lead

• Check for shorted SCR; replace if necessary

Voltage Unbalance F10

• Supply unbalance is greater than the user-

programmed value

• The delay time is too short for the application

• Check power system and correct if necessary

• Extend the delay time to match the

application requirements

Phase Reversal F16

• Incoming supply voltage is not in the

expected ABC sequence

• Check power wiring

Undervolt F4

• Supply voltage is less than user-programmed

value

• The delay time is too short for the application

• Check power system and correct if necessary

• Correct the user-programmed value

• Extend the delay time to match the

application requirements

Overvolt F5

• Supply voltage is greater than user-

programmed value

• Check power system and correct if necessary

• Correct the user-programmed value

Overload F7

• Motor overloaded

• Overload parameters are not matched to the

motor

• Check motor overload condition

• Check programmed values for overload class

and motor FLC

Stall F6

• Motor has not reached full speed by the end

of the programmed ramp time

• Correct source of stall

Jam F19

• Motor current has exceeded the user

programmed jam level.

• Correct source of jam

Underload F9

• Broken motor shaft

• Broken belts, toolbits, etc.

• Pump cavitation

• Repair or replace motor

• Check machine

•Check pump system

Open Gate

(with phase indication)

F23-F25

• Open gate circuitry

• Loose gate lead (180–1000A)

• Perform resistance check; replace power

module if necessary

• Check gate lead connections to the interface

board

Excess Starts/Hr. F64

• Number of starts in a one hour period has

exceeded the value programmed

• Wait an appropriate amount of time to restart

• Turn off the Starts/Hr. feature

Controller Temperature F8

• Controller ventilation blocked

• Controller duty cycle exceeded

• Fan failure (if used)

• Ambient temperature limit exceeded

• Failed thermistor

• Failed control module

• Check for proper ventilation

• Check application duty cycle

•Replace fan

• Wait for controller to cool or provide external

cooling

• Replace power module

• Replace control module

Comm Fault F21

• Communication disconnection at the serial

port

• Check for a communication cable

disconnection to the SMC Dialog Plus

controller

System Faults

F128 &

above

• Internal control module hardware failure • Replace control module

MPU Comm Fault — • Internal control module hardware failure • Replace control module

Curr Fdbk Loss F20

• Converter module cable disconnection • Inspect converter module cable and

connections

Loading...

Loading...