ROXELL - 031 - 0516

FLEX-AUGER - INSTALLATION INSTRUCTIONS

III-23

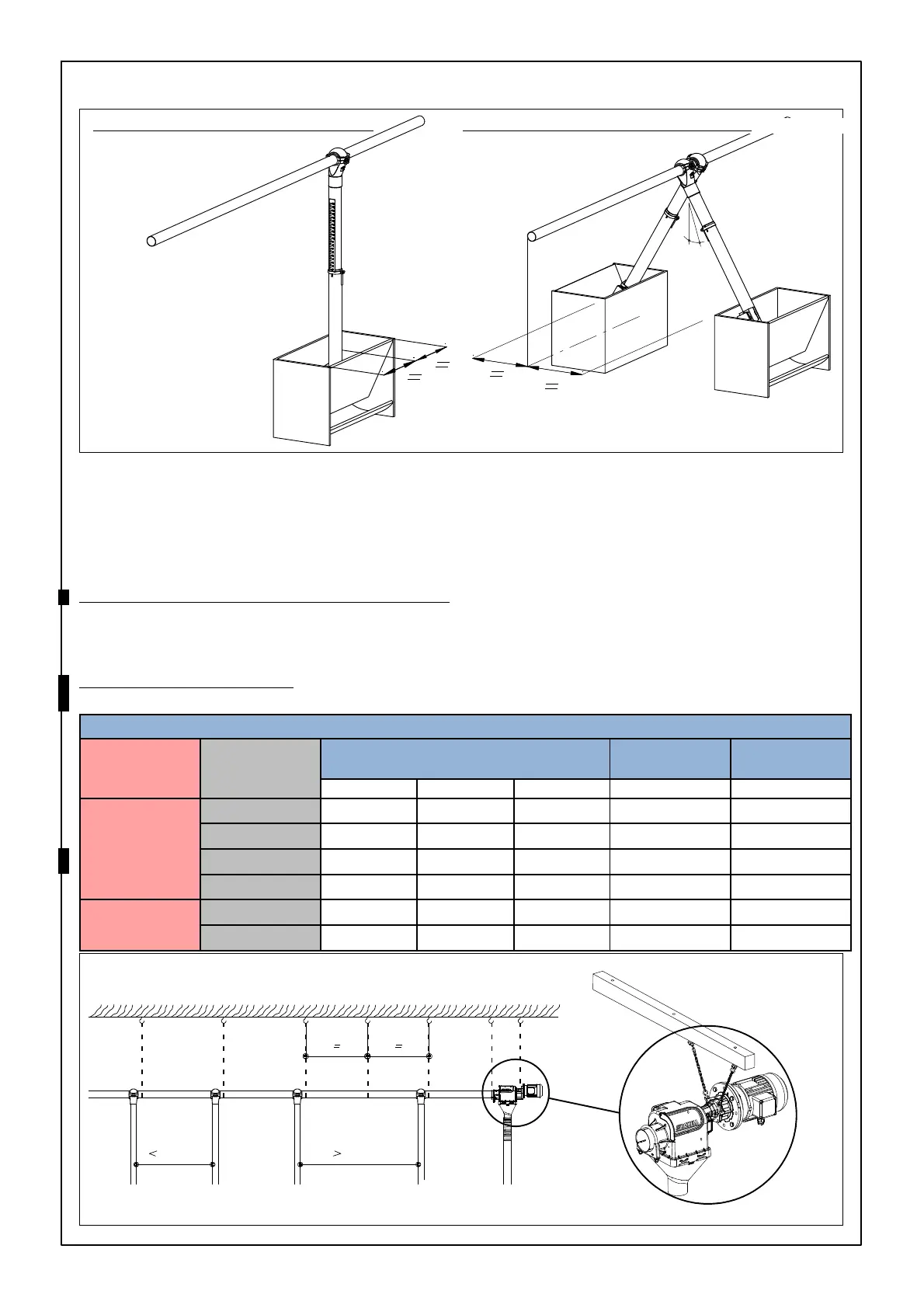

TRANSPORT LINE LOCATION

SINGLE ROW OF FEEDING TROUGHS

- in a feeding trough : against the

back wall.

- in 100kg hopper : in the center.

Install the drop tube.

FIGURE 26.

Suspend the line in the cen-

ter.

DOUBLE ROW OF FEEDING TROUGHS

Max. 45º

pellets

Max. 30º meal

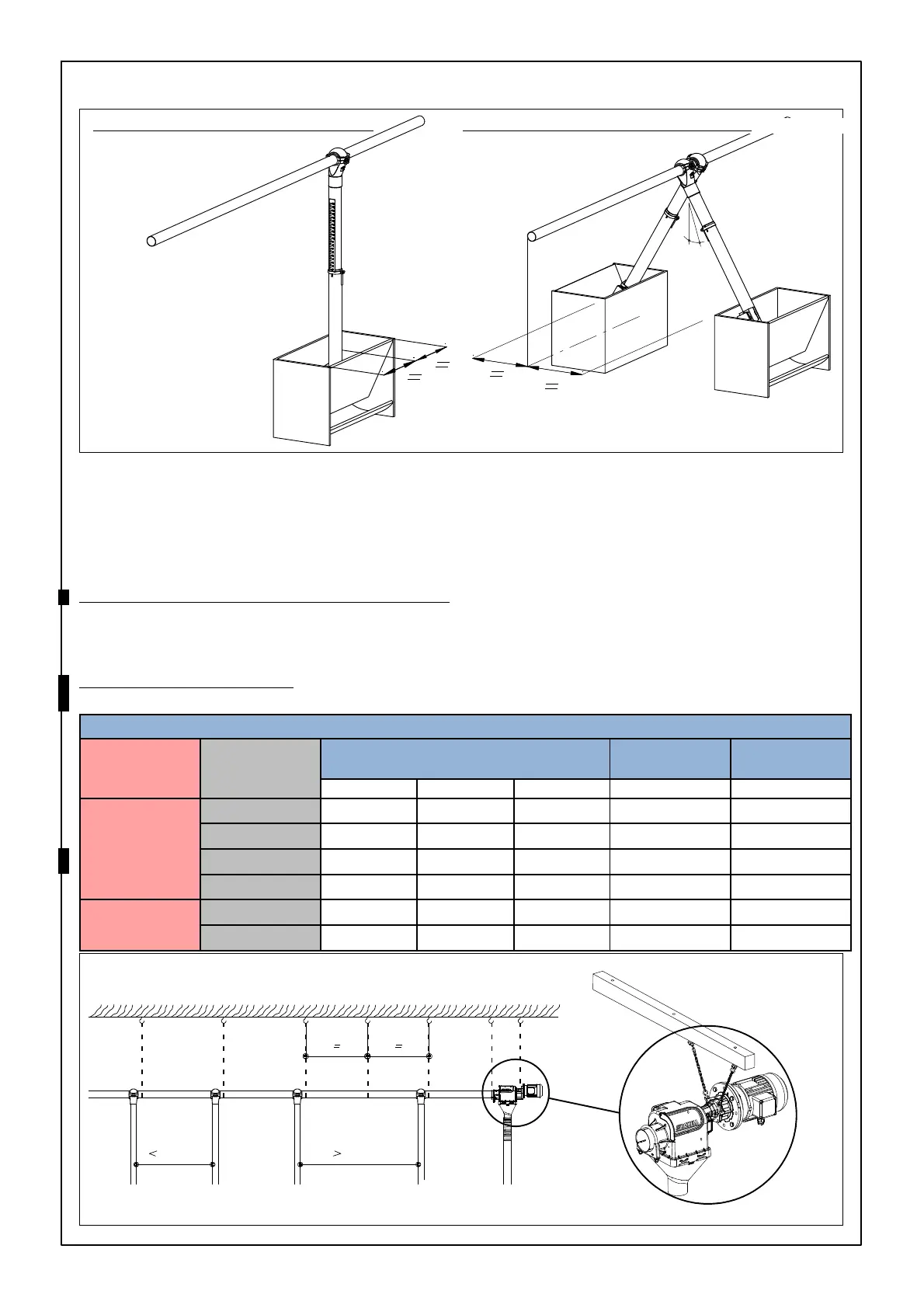

DISTANCE BETWEEN SUSPENSION POINTS

Recommendation: SUSPEND ALL Flex-Auger components !

Suspension in auger direction (no fixation of tube support).

Maximum tensile force of the S-hook : 60kg.

Closing the S-hook increases the resistance.

MODEL

55, 75, 90 AND 125 (NOVICOR/DENSICOR)

If distance between outlets is less than 2m , use one suspension per outlet.

Fordistancemorethan2m:useanextrasuspensioninbetween.

For tubes without outlets: suspension every 2m.

MODEL 90

AND 125 (METAL)

One suspension per 3M.

Maxload(kg) (inclusivesafetyfactor3)

Material Tube Flex Auger

Flex-Auger length

Extension

boot

Power unit

1m 2m 3m

NOVICOR/

DENSICOR

FA55 6 13 53 59

FA75 14 28 68 74

FA90 16 33 87 93

FA125 29 59 98 94

METAL

FA90 67 87 93

FA125 118 98 94

FIGURE 27.

2m 2m

FIGURE 28.

Loading...

Loading...