FLEX-AUGER - INSTRUCTIONS FOR THE USER

ROXELL - 031- 0516

I-4

OPERATOR'S GUIDE

ACTIONS IN GREY BACKGROUND MUST BE DONE BY A TECHNICALLY TRAINED PERSON.

1. Never let the Flex-Auger run without feed. When the Flex-Auger runs empty, the life time ot the system

is reduced considerably.

2. Open the slide valve under the bin completely when the system runs with mash or pellets. Always use a thumper

when feeding mash. Always use pellet guides when feeding pellets (close the flow regulator).

3. THE LEVEL SWITCH IS INSTALLED LOW INSIDE THE LAST FEEDING TROUGH OR HOPPER.

See that there are enough animals in the last pen : they empty the trough completely, so that fresh feed will be

supplied at all times.

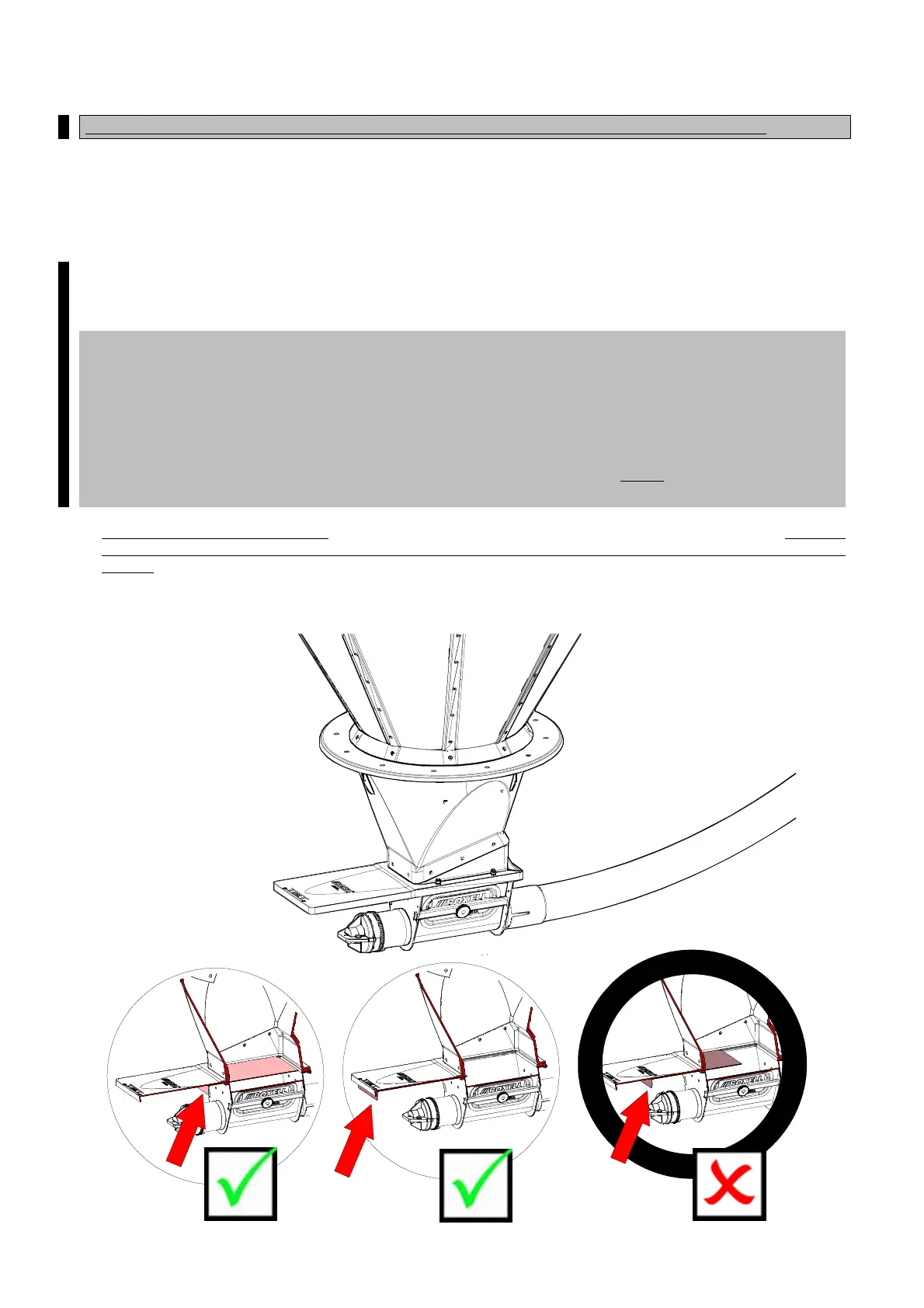

4. The r estrictor on the boot anchor adjusts the amount of feed taken away by the auger.

Start any new system with the restrictor in minimum position. Let the system run a while before you adjust the

feed flow, allowing the auger to be cleaned by the feed.

You obtain minimum feed flow by moving the restrictor as far as possible away from the anchor.

In a Flex-Auger system with EXTENSION BOOT, the second part must convey more feed than the first part.

Adjust the restrictor in the int ake boot with restrictor (beneath the weigher, daybin, bin....) if necessary.

5. If the F lex-Auger starts from a tandem system : empty one bin after another. Never

feed from both bins at the

same time. When one of the bins is empty, remove the thumper (if used).

6. Maximum running time per day : 4 hours (system without elbows) / 2 hours (system with elbows). For layer

feed and any feed other than commercial feed or poultry and pigs, the maximum running times are

considerably

shorter

!

7.

Useoftheslidevalve:

Loading...

Loading...