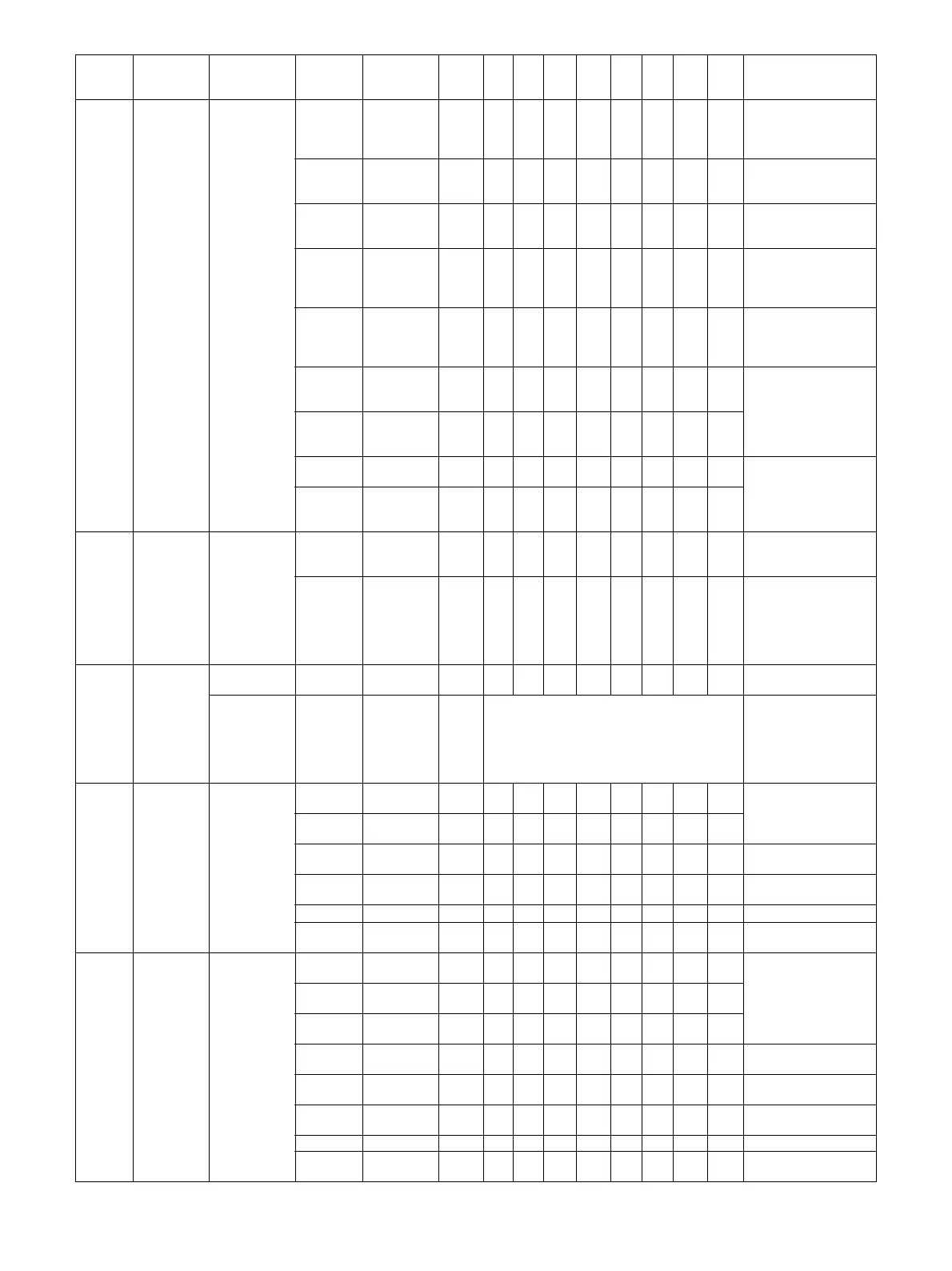

MX-3114N MAINTENANCE 9 – 6

3 Transfer

section

Secondary

transfer unit

1 Secondary

transfer belt

follower

roller

––– –– ––

2 Secondary

transfer belt

––– –– – – Never use alcohol or

solvents for cleaning.

Replace at every 300K.

3 Secondary

transfer belt

drive roller

––– –– ––

4 Secondary

transfer

backup

roller

––– –– ––

5 Secondary

transfer belt

tension

roller

––– –– ––

6 Secondary

transfer

roller

–––✕ ––✕ – – Replace as needed.

7 Secondary

transfer

drive gear

–––✕ ––✕ ––

8 Separation

cam

–––✩ ––✩ – – When replacing, apply

HANARL FL-955R to

the shaft section.

9 Secondary

transfer

frame

–––✩ ––✩ ––

4 Other Other 1 PTC unit – Replace. Reciprocate

the PTC cleaning rod

back and forth 3 times.

2 Image

density

sensor

– Remove dirt from the

light emitting/receiving

sections (transparent

plastic sections) of the

sensor with dry waste

cloth. *

1

5 LSU section LSU 1 Dust-proof

glass

Use the LSU cleaning

rod.

Other 2 Cleaning

base

✕ Replace every time the waste toner box is

replaced.

Attached to the waste

toner box. (2 pcs.) /

Replace when the

waste toner box is

replaced, or at 100K, or

2 years of use.

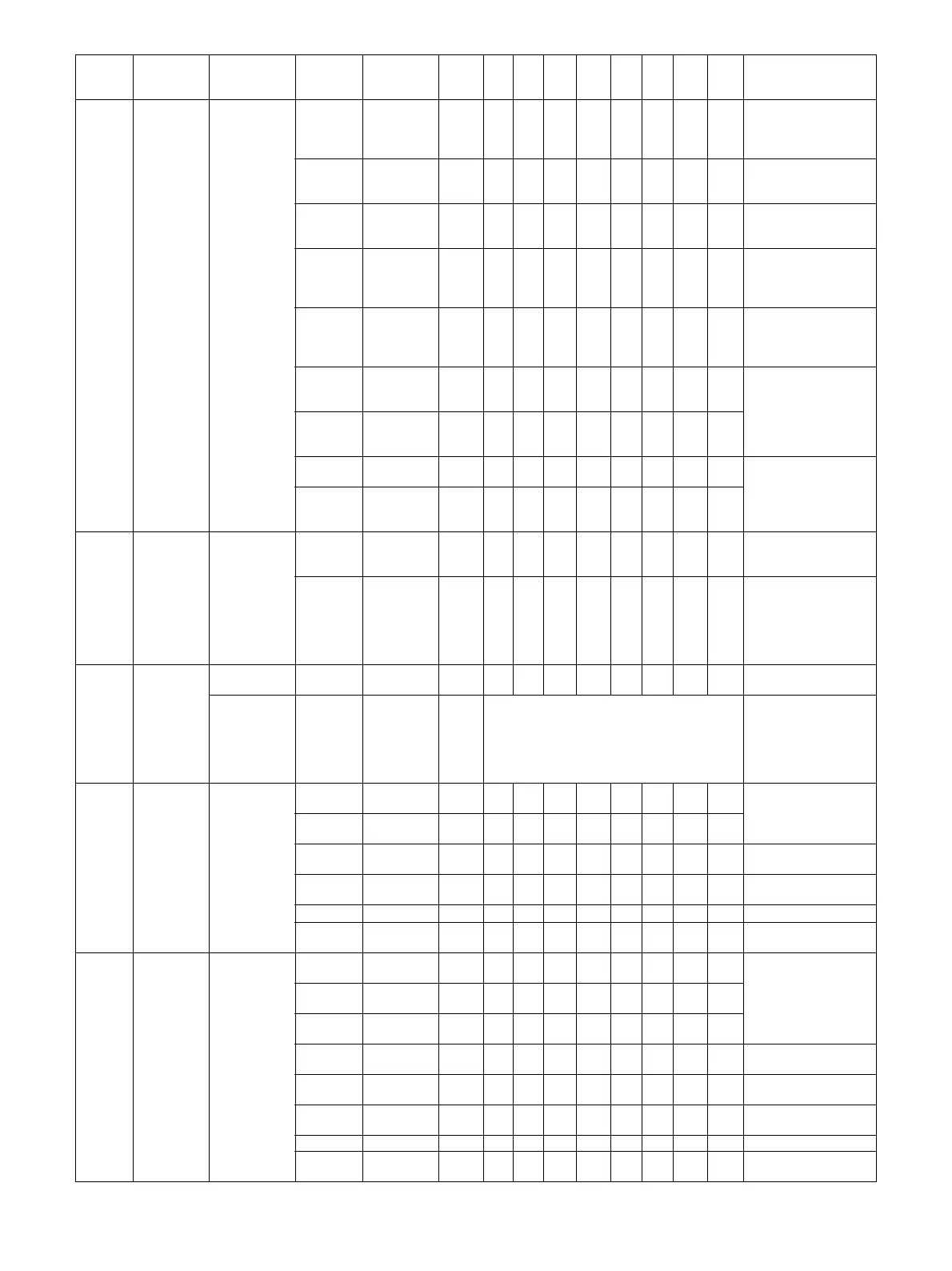

6 Manual

paper feed

section

Manual paper

feed unit

1 Paper feed

roller

✕ Replace at 100K of the

manual paper feed

counter or 1 year of use.

2 Separation

roller

✕

3 Torque

limiter

✕✕✕✕✕✕✕✕✕

4 Transport

roller 9

✕

5

Sensors ✕✕✕✕✕✕✕✕✕

– Paper

guides

Clean with alcohol.

7 Tray paper

feed section

Tray paper

feed unit

1 Paper

pickup roller

✕ Replace at 100K of the

tray paper feed counter

or 1 year of use.

2 Paper feed

roller

✕

3 Separation

roller

✕

4 Transport

roller 4

✕

5 Transport

roller 2

✕

6 Torque

limiter

✕✕✕✕✕✕✕✕✕

7Sensors ✕✕✕✕✕✕✕✕✕

– Paper

guides

Clean with alcohol.

Section/

Unit work

sequence

Section name Unit name

Parts work

sequence

Part name

When

calling

100

K

200

K

300

K

400

K

500

K

600

K

700

K

800

K

Remark

Loading...

Loading...