MX-3114N MAINTENANCE 9 – 13

* 1: Note for cleaning the image registration/density sensor.

When in maintenance or in case a service call, refer to "Criteria for necessary of cleaning" below to judge the necessity of cleaning the image

registration/density sensor. If it is judged that cleaning is necessary, then perform cleaning

Criteria for necessity of cleaning

• The SIM44-2 item D/E/F value is increased by aging or dirt of the image density sensor.

• When the image density is decreased, execute SIM44-2 and execute SIM46-74 Copy balance adjustment.

Greasing

Greasing is not always required for every maintenance. In the fol-

lowing cases, check and grease.

• When there are some noises.

• When a lot of jams occur frequently. (Check the jam history.)

For the part code of grease to be used, refer to "[15] TOOL LIST."

Cleaning of sensors and detectors in the paper feed/transport

system

Cleaning of sensors and detectors in the paper feed/transport sys-

tem is not always required for every maintenance. In the following

cases, check and clean.

• When a trouble or a jam occurs due to a sensor or a detector.

(Check the jam history.)

Torque limiter check and replacement

Torque limiter check and replacement is not always required for

every maintenance. In the following cases, check and replace.

• When there are some noises.

• When a lot of jams occur frequently. (Check the jam history.)

Alcohol for cleaning

Be sure to use ethanol for cleaning.

Cleaning of the primary transfer mode detector (CL/BK)

• When replacing the OPC drum, remove the primary transfer unit

and the developing unit, and clean them.

• Blow air to the light emitting section and light receiving section to

remove the attached toner.

• Blow air also when the sensor is wiped and cleaned with waste

cloth.

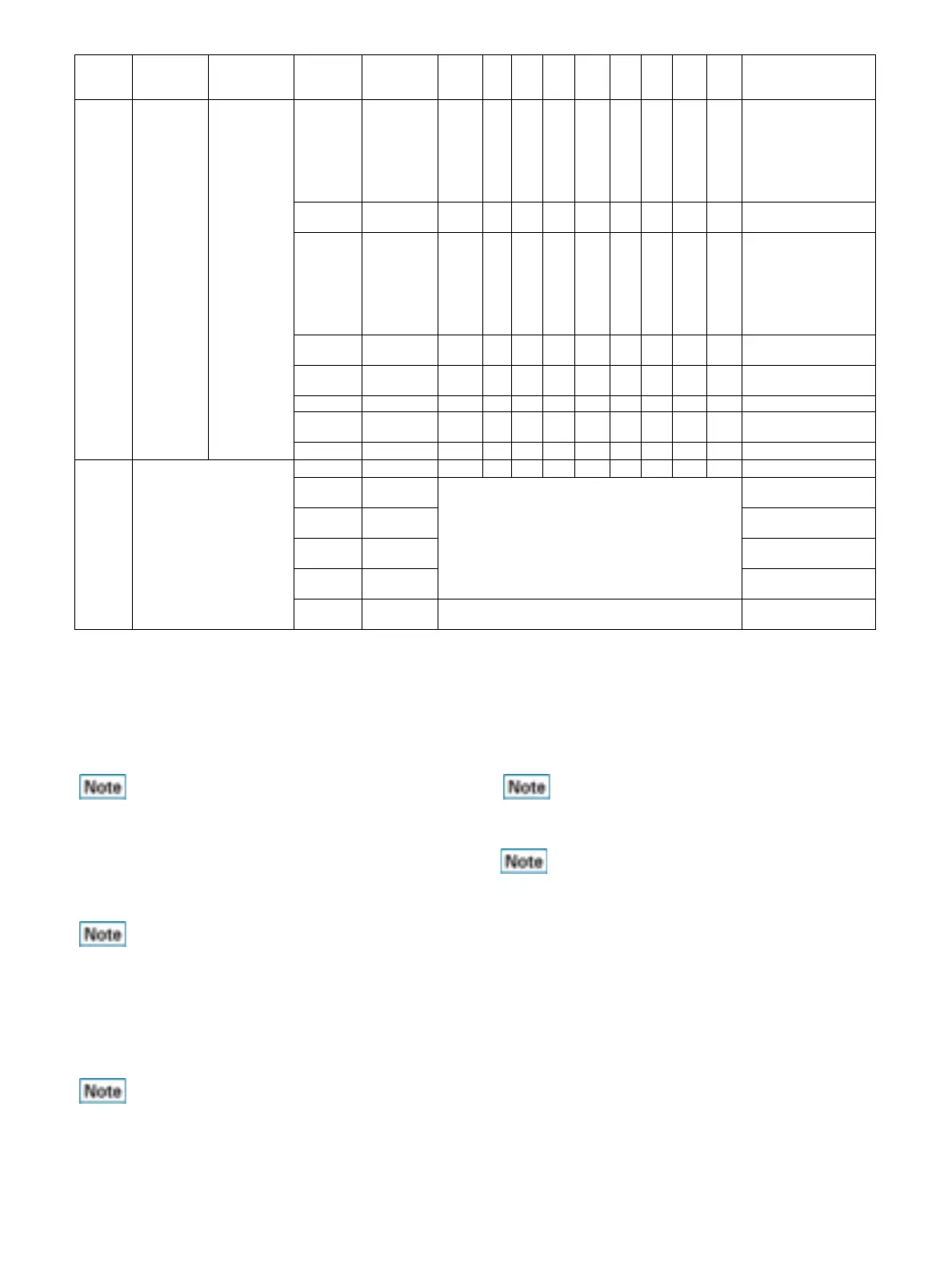

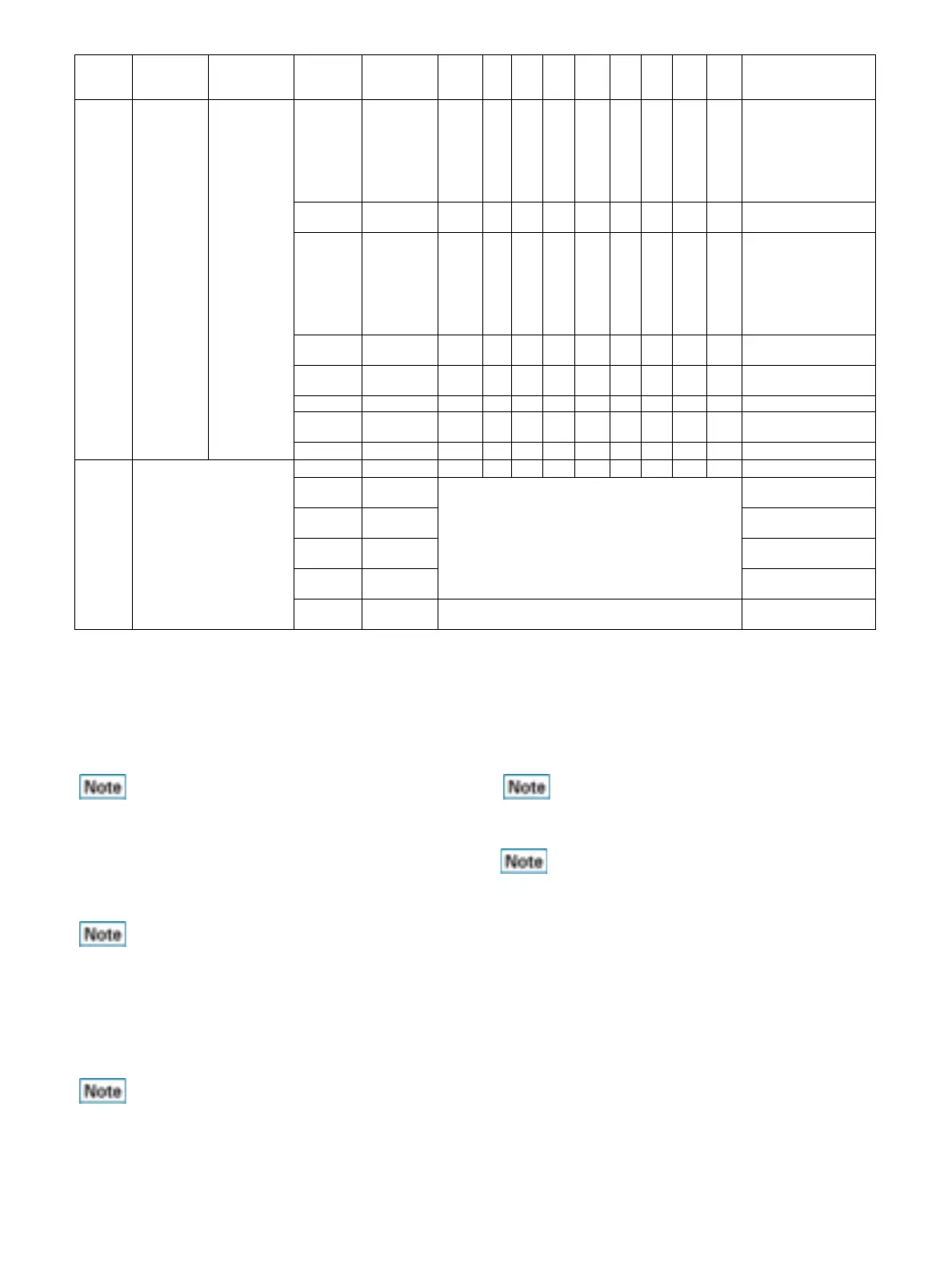

10 Fusing

section

Fusing unit 17 Fusing roller ✕ – – Apply grease to the

shaft section when

replacing. (JEF552) /

Integrated with the

pressure roller as a

maintenance kit.

Replace at every 200K.

18 Heating

roller

✕✕– ✕✕✕– ✕✕Replace as needed.

19 Fusing belt ✕ – – Integrated with the fuser

belt guide collar as a

maintenance kit. / When

replacing, clean the

fusing belt surface with

alcohol.

Replace at every 200K.

20 Main

thermistor

✕✕– ✕✕✕– ✕✕Replace as needed.

21 Paper

guides

– –

22 Gears ✕✕– ✕✕✕– ✕✕Replace as needed.

23 Pressure

spring

✕✕– ✕✕✕– ✕✕

24 Washer ✕✕– ✕✕✕– ✕✕

11 Other 1 Ozone filter – – – – –

2 Toner

cartridge BK

User replacement for every toner empty.

3 Toner

cartridge C

4 Toner

cartridge M

5 Toner

cartridge Y

6 Waste toner

box

Replaced by the user when full is detected. Replacement reference:

50K

Section/

Unit work

sequence

Section name Unit name

Parts work

sequence

Part name

When

calling

200

K

300

K

400

K

600

K

800

K

900

K

1000

K

1200

K

Remark

Loading...

Loading...