Operating Instructions Chapter 4

M4000 Adv., Adv. A/P, Area

8010797/PA53/27-06-05 © SICK AG • Industrial Safety Systems • Germany • All rights reserved

23

Configurable functions

WARNING

Use different beam codings if the systems are mounted in close proximity!

Systems mounted in close proximity to each other must be operated with different beam

codings (code 1 or code 2). If this precaution is neglected, the system may be impaired in

its protective function by the beams from the neighbouring system and so change to the

unsafe state. This would mean that the operator is at risk.

• Beam coding increases the availability of the protected machine. Beam coding also

enhances the resistance to optical interference such as weld sparks or similar.

• Within a system you must configure the beam coding for every device (sender and

receiver) separately.

• In a cascaded system the host and guest always have the same beam coding. There is

no mutual interference.

• After switching on, the 7@segment display of sender and receiver will briefly display the

coding.

Device symbol M4000 Advanced (sender or receiver), M4000 Advanced (A/P) or M4000

Area (sender or receiver), context menu Open device window, parameter node General.

4.3 Application diagnostic output (ADO)

The M4000 has an application diagnostic output (ADO) that can be configured. With the

aid of the application diagnostic output, the multiple light beam safety device can signal

specific states. You can use this output for a relay or a PLC.

WARNING

You must not use the application diagnostic output for safety-relevant functions!

You are only allowed to use the application diagnostic output for signalling. You must

never use the application diagnostic output for controlling the application or with safety-

relevant functions.

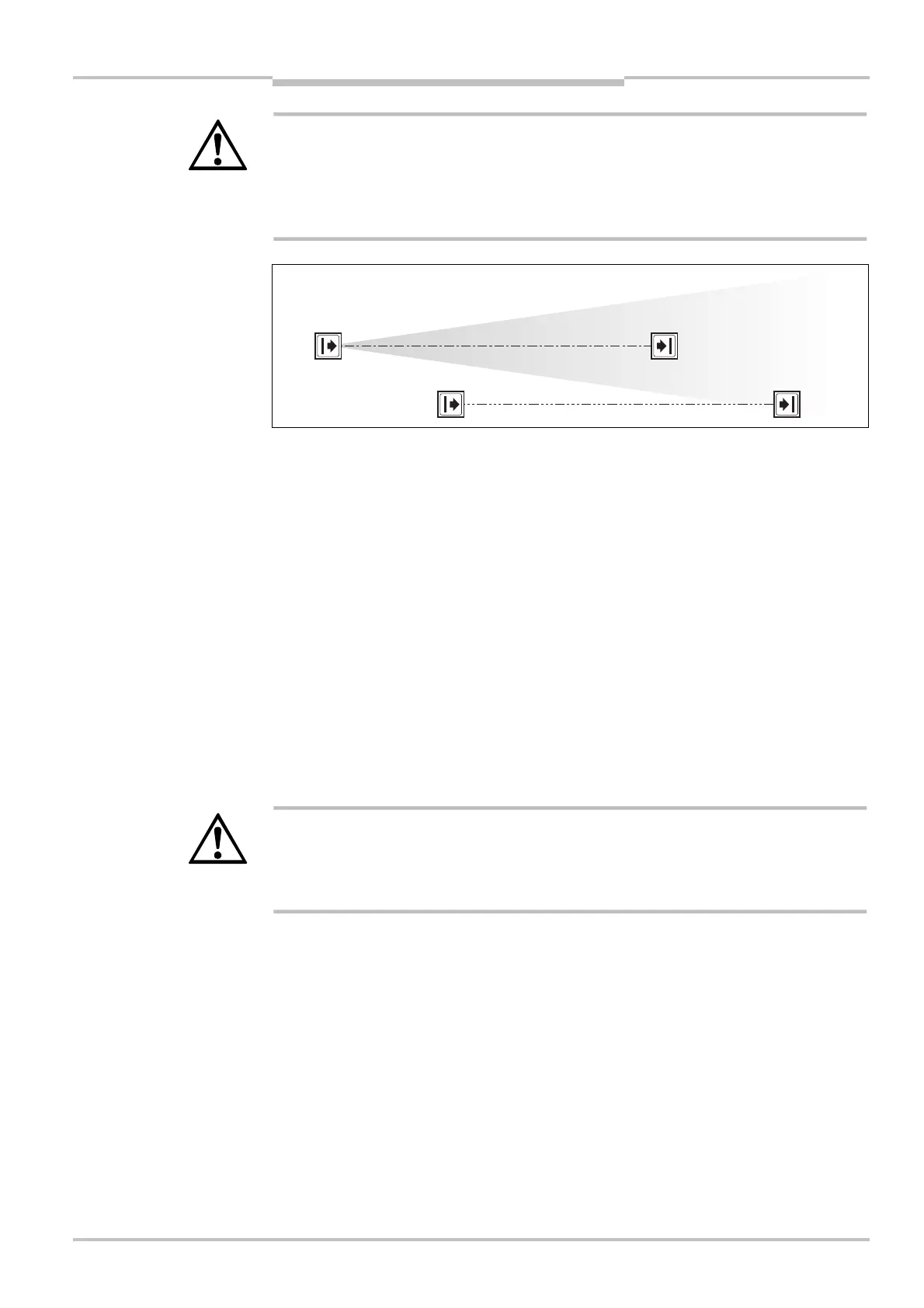

Fig. 15: Schematic

illustration of the beam

coding

Notes

AUDIN - 7 bis rue de Tinqueux - 51100 Reims - France - Tel : 03.26.04.20.21 - Fax : 03.26.04.28.20 - Web : http: www.audin.fr - Email : info@audin.fr

Loading...

Loading...