Commissioning Manual

234 01/2017

Press this softkey to confirm your settings and go to the motor configur

ation window.

Use the cursor keys to select the right motor ID according to the motor rating plate.

Press this softkey to confirm your selection and return to the drive list window.

●

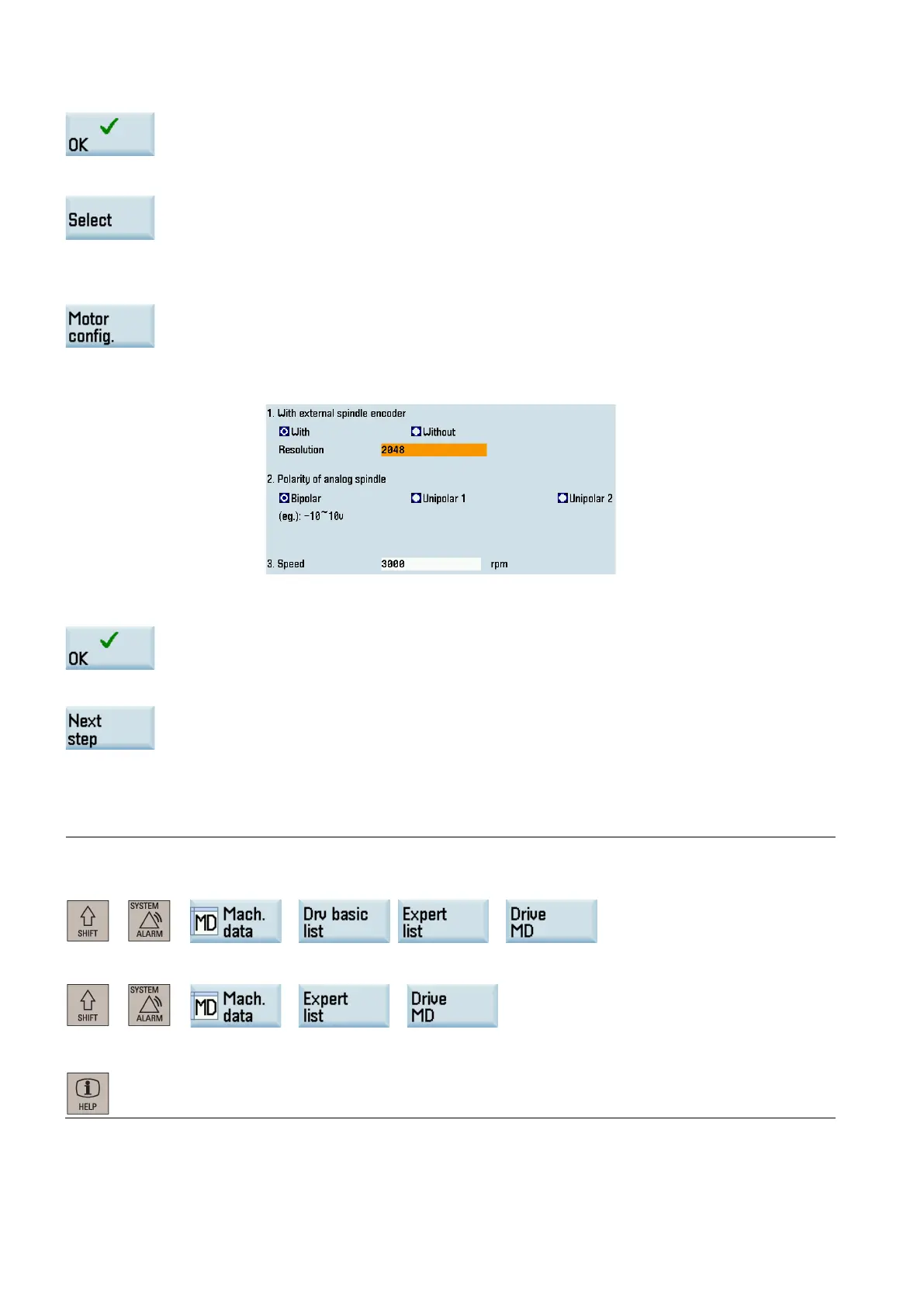

Configuring the analog spindle

Use the cursor keys to select the spindle MSP1 in the drive list window.

Press this softkey to open the spindle configuration win

dow.

Use the cursor keys to make the desired selections in the following window a

c

cording to the

actual application, and enter relevant values where applicable:

For more information about the polarity of analog spindle, see Section "

Analog spindle inter-

face - X54, spindle encoder interface - X60 (Page 99)".

Press this softkey to confirm your settings and return to the drive list window.

After you finish configuring all axes and the spindle, press this softkey to save the conf

iguration

results on both CNC and drives and proceed to the next st

ep.

The control system restarts after you press this softkey. In this case, for the drive connected

to a motor with an incremental encoder, immediately after the "RDY" LED on the drive lights up

green, the motor makes a short buzzing sound indicating

that the motor is identifying the magnetic

pole position of the rotor.

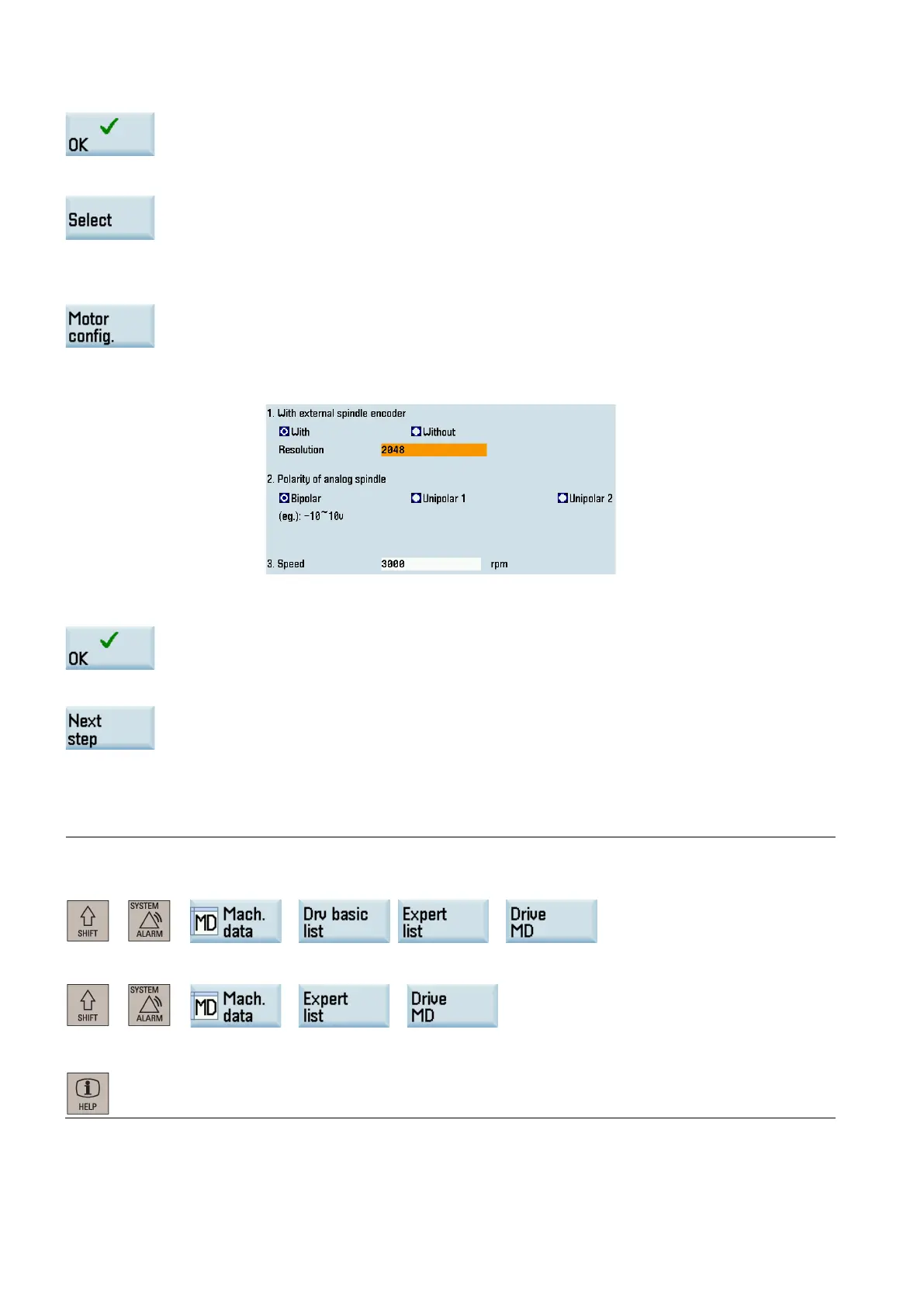

Note

You can change the motor direction of rotation by setting the drive parameter p1821. The parameter p1821 is accessible on

the PPU th

rough the following operations:

+ → → /( → )

Before changing the parameter p1821, first set the drive

parameter p10 = 3 when the drive is in "S OFF" state. Parameter

p10 is accessible on the PPU th

rough the following operations:

+ → → →

For detailed explanation about the drive parameters, you can call the online help by pressing the following key on the

corresponding drive parameter

screen:

Loading...

Loading...