14.7.5 Supplementary condition

Tool changes

If, in a machine model, tools change as a result of being replaced/exchanged or wear without

programming a tool offset selection (D number), then the recalculation of the machine model

must be explicitly requested. You will find more precise information in:

Function Manual Special Functions (FB3); collision avoidance (K9),

Chapter: "Function description" > "Tools"

14.8 Collision avoidance example

14.8.1 Fundamentals

General Information

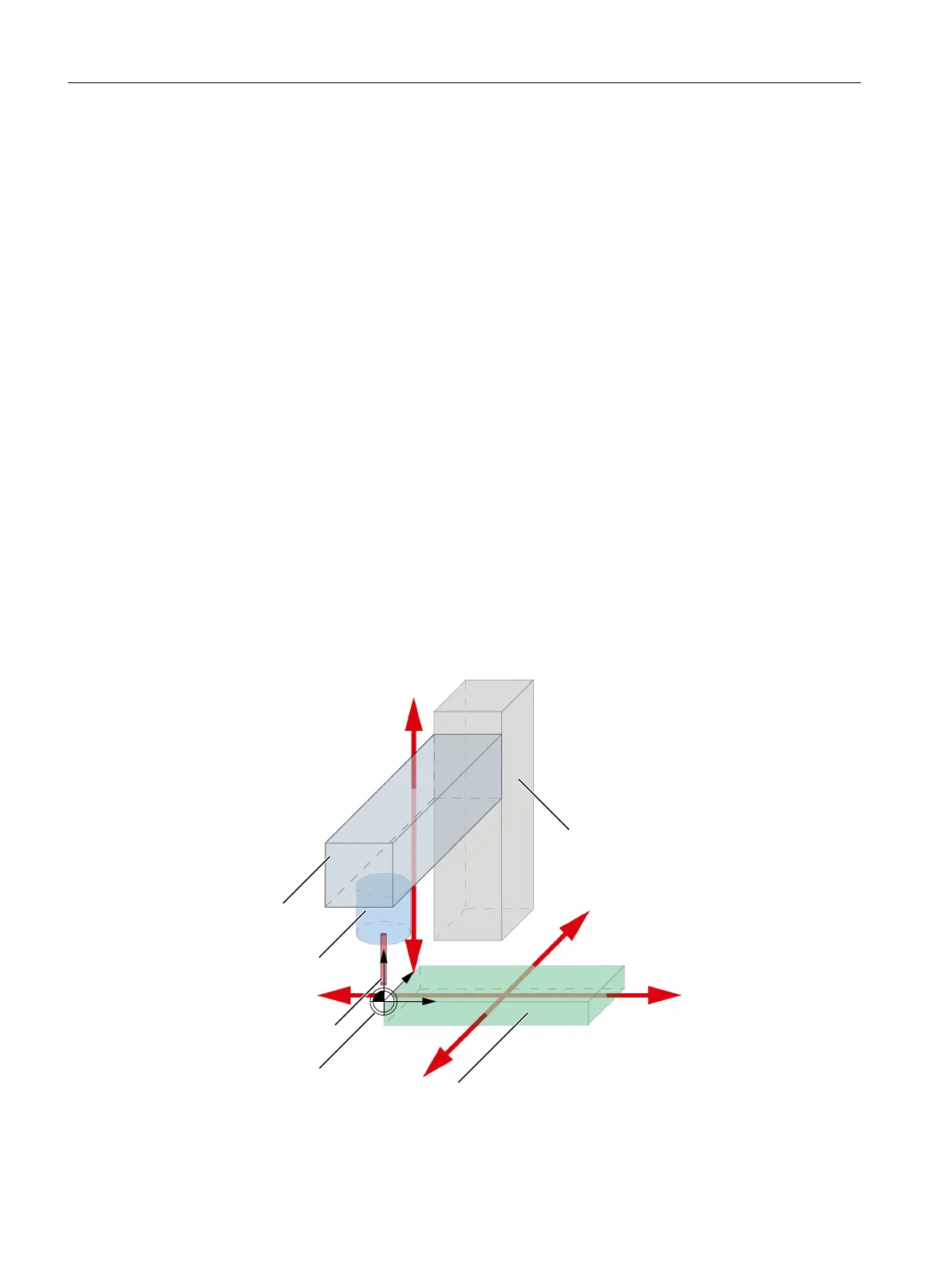

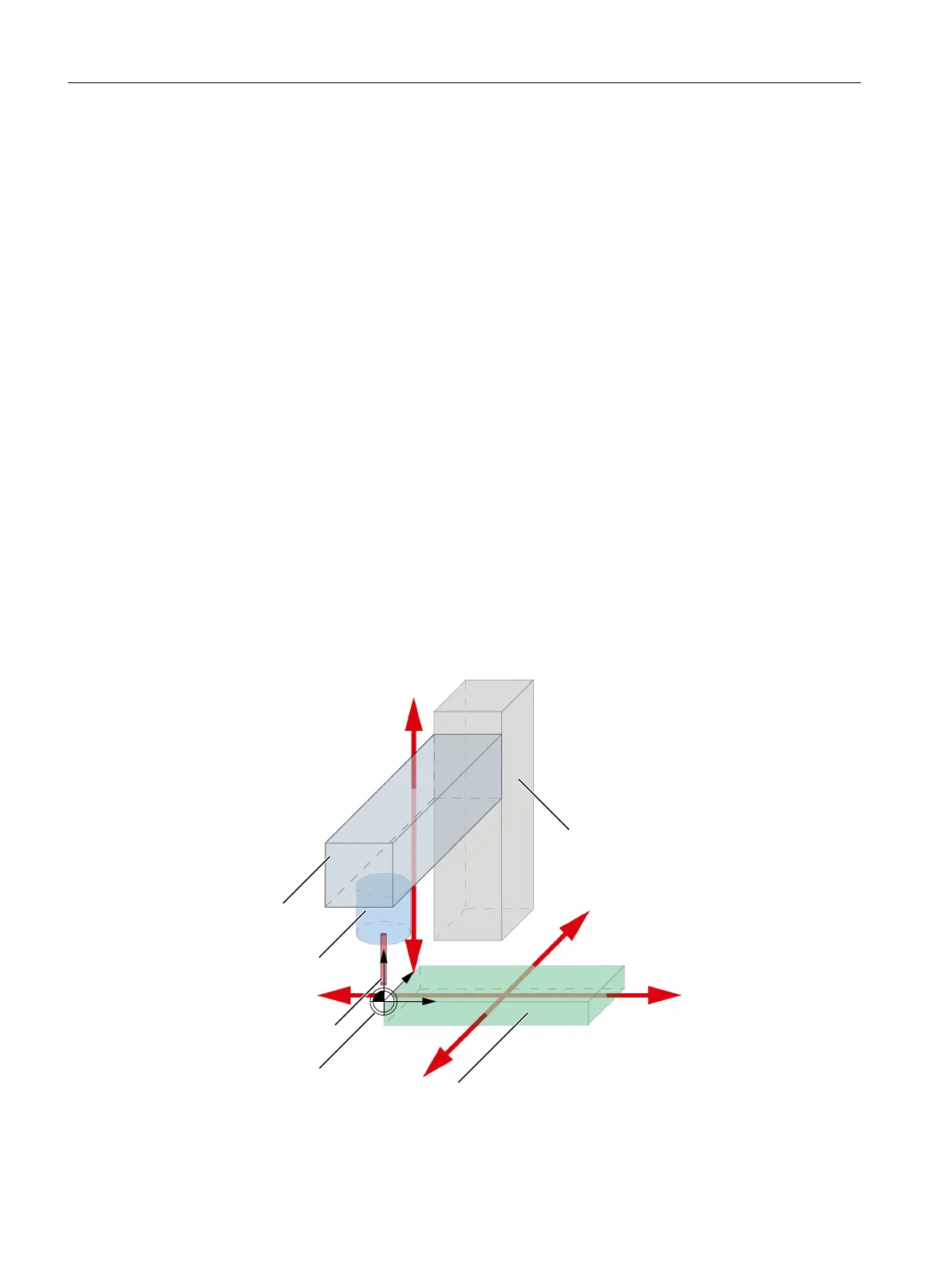

The following example contains the machine model elements of a simple 3-axis milling

machine for a simplified kinematic chain.

Machine model elements

;

<

=

7RROKROGHU

7RRO

7DEOH

=D[LV

6WDQG

0DFKLQH]HUR

5HIHUHQFHSRLQW

;

<

=

Collision avoidance

14.8 Collision avoidance example

SINUMERIK Operate (IM9)

320 Commissioning Manual, 12/2017, 6FC5397-1DP40-6BA1

Loading...

Loading...