The Y measurement read should be the same as the theoretical one (value = 500 expressed in brackets).

If not, proceed as follows:

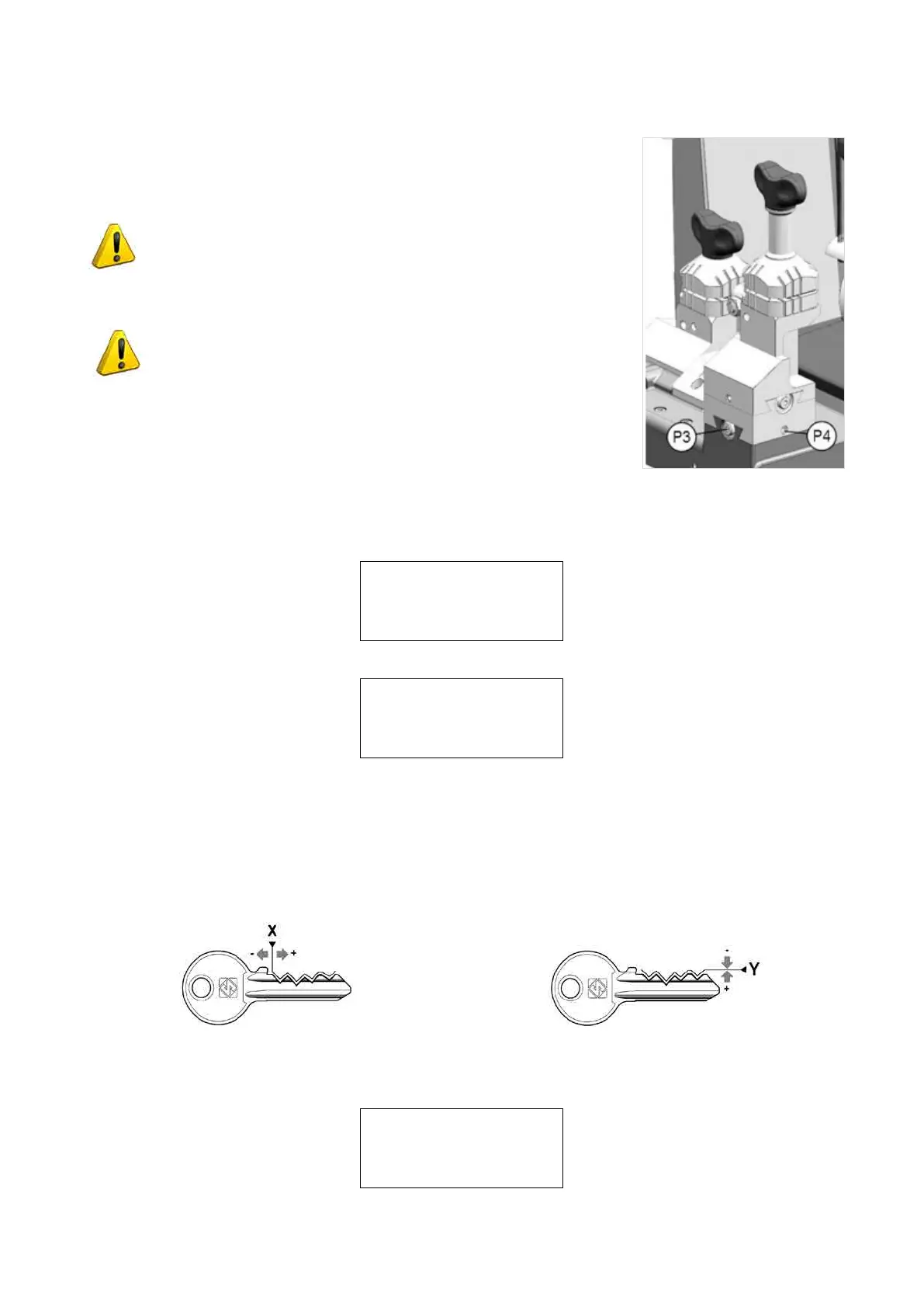

• For Y values of less than 500, loosen the grub screw (P3) and use the hex.

wrench to tighten the screw (P4)

ATTENTION: a quarter turn of the screw (P4) makes a movement

of approx. 19 hundredths of a millimetre.

• For Y values of over 500, loosen the grub screw (P3) and use the hex. wrench

to tighten the screw (P4).

ATTENTION: a quarter turn of the screw (P4) makes a movement

of approx. 19 hundredths of a millimetre.

Fig. 56

Tighten the grub screw (P3) and press START to repeat the operation until the X and Y values are correct.

When the values read for X and Y are the same as the theoretical ones (expressed in brackets), press STOP.

The display will show:

Conrmyouwantto

quit the gauging

procedure?

No=STOP Yes=ENTER

PressENTER(*)toconrm.Thedisplaywillshow:

L100-STANDARD S: A

Manual adjustment:

X=+000 Y=+000

To calibrate [START]

Press START to re-start the gauging cycle.

Press STOP.

5.7.1.1-a MANUAL ADJUSTMENTS

WhentheautomaticcalibrationprocedureisnishedforclampL100(Side:A)adjustmentstoX(spaces)andY

(depths) can be made manually for sides B - C - D.

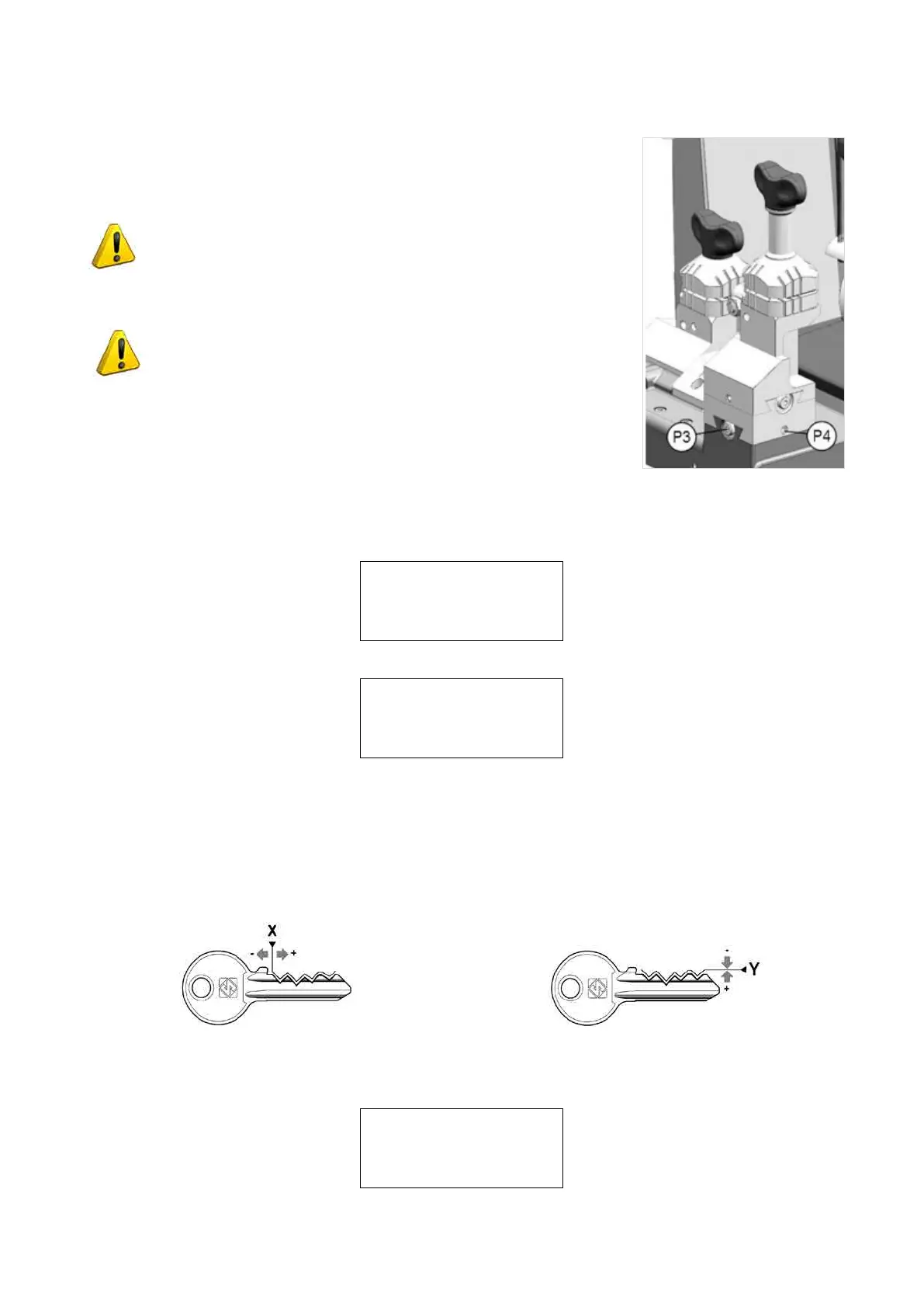

Fig. 57 - SPACING ADJUSTMENT (X) Fig. 58 - DEPTH ADJUSTMENT (Y)

Press SHIFT+ENTER to see on the display:

L100-STANDARD S: B

Manual adjustment :

X=+000 Y=+000

Operating Manual UC199

Copyright Silca 2012

46

Loading...

Loading...