- OPTICAL READER CLAMP-

The display will show:

READER CALIBRATION

Install the Z20

template on reading

clamp. [START]

TheZ20templateshouldbetted,otherwise:

-

Raise the safety shield.

-

Fit the Z20 template on side A of the reading clamp, as if it were a key, and use the gauge as a stop.

-

Lower the gauge and safety shield.

Press START. The display will show:

Reading in progress

X POSITION READING:

X=404 (400)

See operatine manual.

[START]

NOTE: Note: X deviations of +/- 20 hundredths of a mm from the theoretical measurement can be

considered insignicant. Press START to conrm gauging without mechanical regulation.

The X measurement read should be the same as the theoretical one (value = 400 expressed in brackets).

If not, proceed as follows:

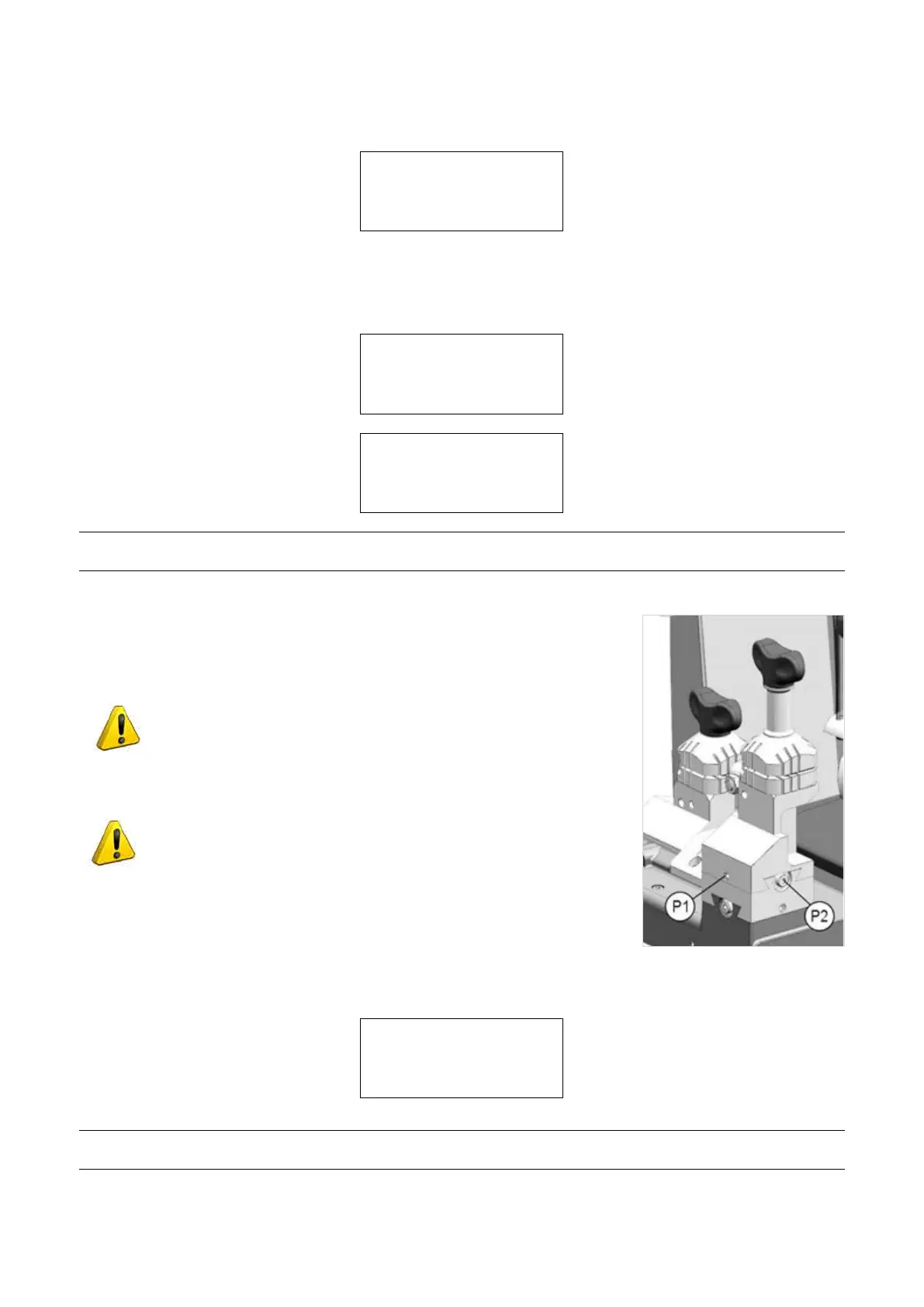

• For X values of less than 400, loosen the grub screw (P1) and use the hex.

wrench to loosen the screw (P2).

ATTENTION: a quarter turn of the screw (P2) makes a movement

of approx. 19 hundredths of a millimetre.

• For X values of over 400, loosen the grub screw (P1) and use the hex. wrench

to tighten the screw (P2).

ATTENTION: a quarter turn of the screw (P2) makes a movement

of approx. 19 hundredths of a millimetre.

Fig. 55

Tighten the grub screw (P1) and press START:

Y POSITION READING:

Y=502 (500)

See operatine manual.

To repeat [START]

NOTE: Y deviations of +/- 20 hundredths of a mm from the theoretical measurement can be considered

insignicant. Press STOP to conrm gauging without mechanical regulation.

Operating Manual UC199

Copyright Silca 2012

45

Loading...

Loading...