ATTENTION: always set 1 with UC199.

(*) pulleys cannot be inverted on UC199 Japan (100V-50/60Hz).

3 – CUTTING SPPED:

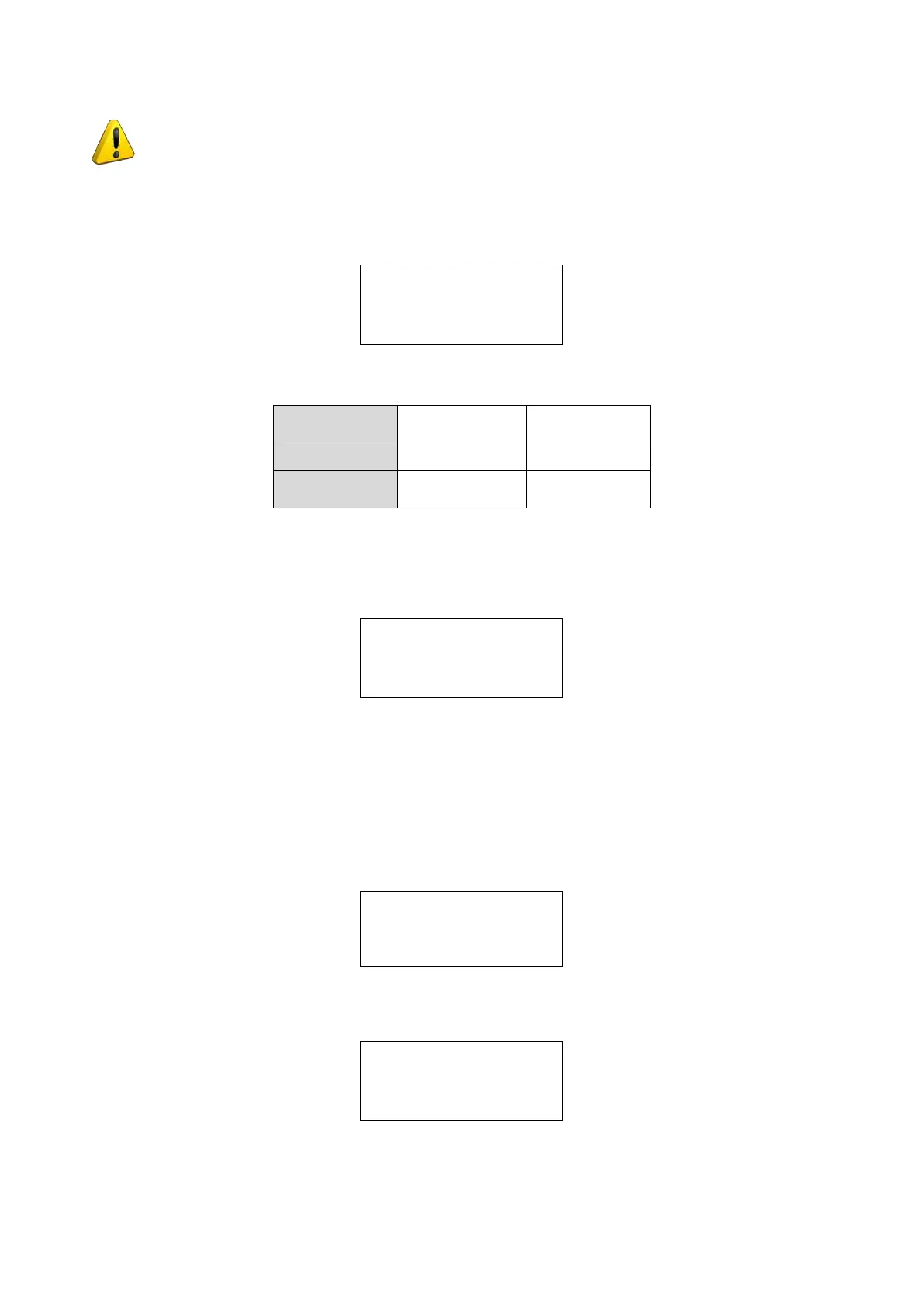

Cutting speed

HSS Hd. Met

250 350

(100-500) (200-700)

Corresponds to the carriage advancement speed during the key cutting operation:

On the basis of the cutter material selected, speed can be altered as shown in the table.

Cutter metal

Recommended

speed

Speed

range

HSS

250 100-500

Hard metal

(carbide)

350 200-700

Operating keys: arrow keys [Up/Down] to go from one eld to another (HSS or hard metal). Arrow keys [< >] to

increase or decrease the speed value. Conrm with ENTER.

4 - CARRIAGE SPEED:

Carriage approach

speed = 4000

(1000-5000)

This is the speed at which the carriages move towards the cutting area, before starting the cutting cycle.

We recommend to operate the machine with the speed that is set (4000). If required, the operator can adjust the

carriage approach speed from a minimum of 1000 to a maximum of 5000.

Arrow keys [< >] to increase or decrease the speed value.

5 - PREFERENCES:

work parameters are chosen from this menu.

1- Measurement unit

2- Start menu

3- Quick menu

4- Adjusted copy

1 / Measurement (inches or millimetres):

choose the viewing method for measurement values (mm = millimetres, inch. = inches).

Measurement unit = 0

( 0=Millimetres )

( 1=Inch )

2 / Start-up menu

choosethefunctionintheMainmenuthatyouwouldliketoappearrstwhenthemachineisturnedon.

Operating Manual UC199

Copyright Silca 2012

61

Loading...

Loading...